Vertical numerical control spring grinding machine

A spring grinding machine and vertical technology, applied in the field of grinding spring machinery, can solve the problems of insufficient precision and smoothness, slow processing efficiency, etc., and achieve the effects of precision and smoothness guarantee, good quality and high output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

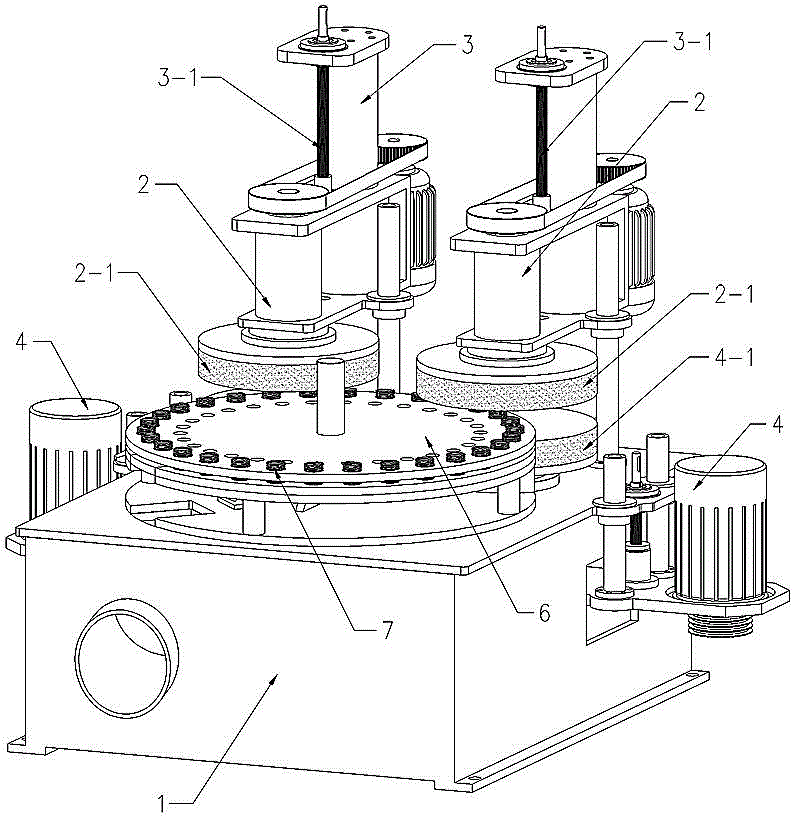

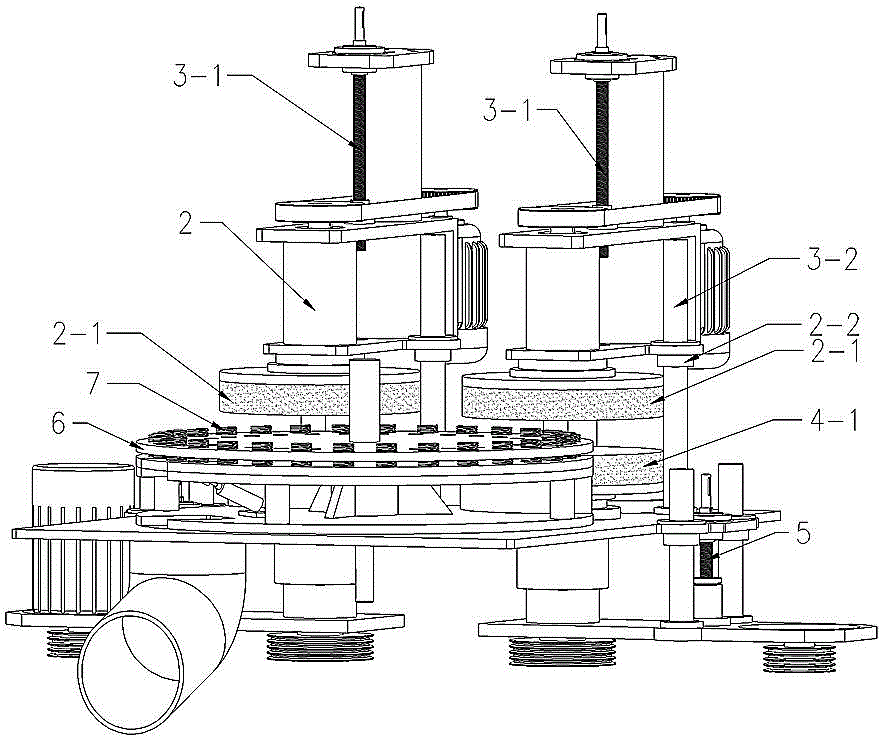

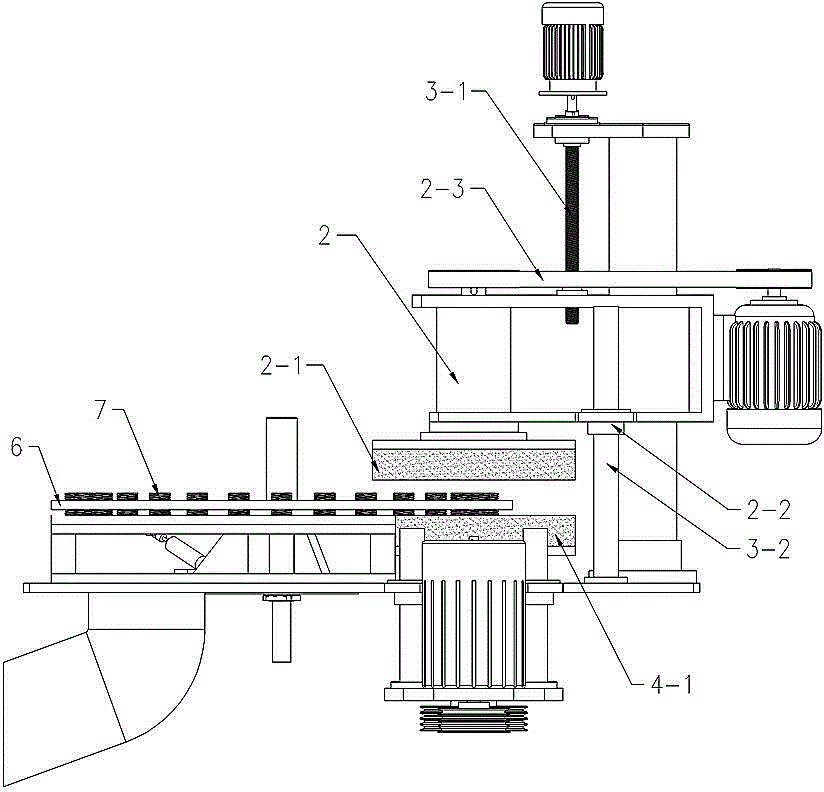

[0017] See attached figure 1 —3, a kind of vertical numerical control spring grinding machine comprises frame 1, grinding disc 6, upper grinding wheel rotating mechanism 2, lower grinding wheel rotating mechanism 4, upper grinding wheel lifting mechanism 3, lower grinding wheel lifting mechanism 5. The die holes for placing the springs 7 are arranged in a circular array on the grinding disc 6, and a grinding wheel is arranged on the top of each grinding wheel rotating mechanism, and is vertically lifted and lifted by the grinding wheel lifting mechanism; this embodiment uses two sets of grinding wheel rotating mechanisms with the same structure and The grinding wheel lifting mechanism is equipped with 4 grinding wheels in total, and there are two kinds of grain sizes; see figure 1 , the upper grinding wheel 2-1 and the lower grinding wheel 4-1 on the left side of frame 1 are coarse grinding wheels of the same particle size; the upper grinding wheel 2-1 and lower grinding whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com