Glass cutting and splitting processing method and device

A glass cutting and sheet processing technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problem that glass cannot be automatically cracked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

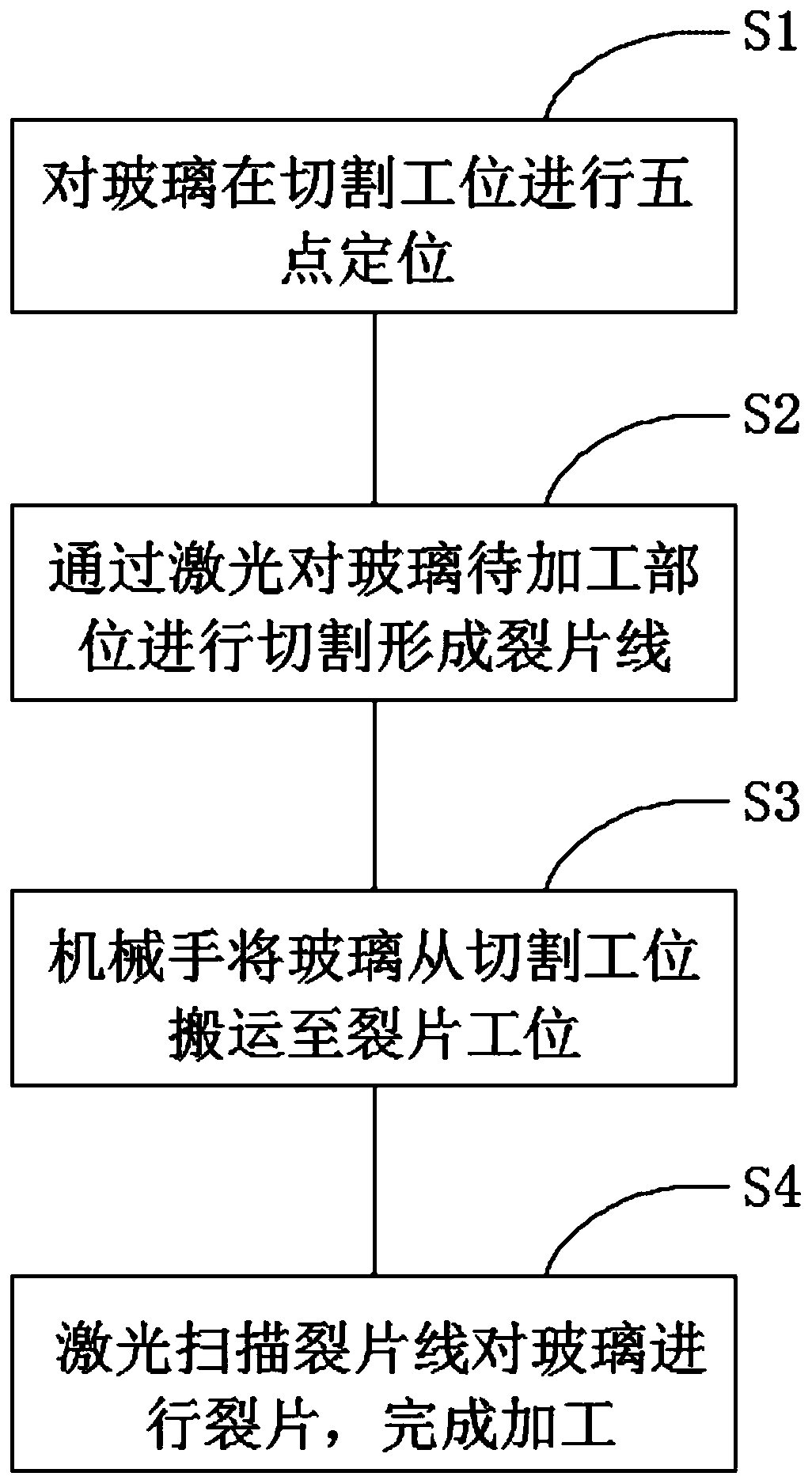

[0035] Such as figure 1 As shown, the present embodiment one provides a glass cutting slivers processing method,

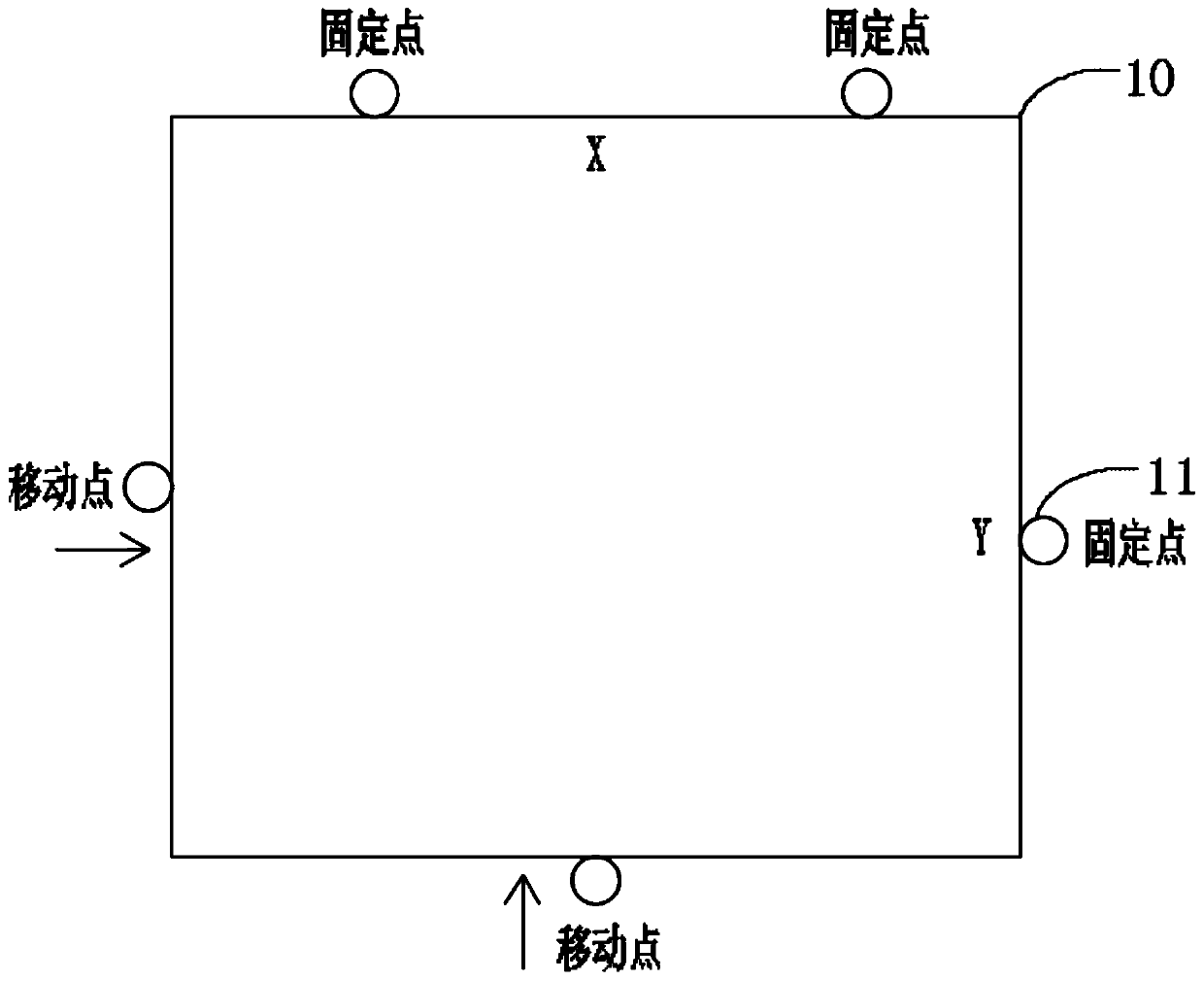

[0036] S101, performing five-point positioning on the cover glass at the cutting station;

[0037] S102, cutting and marking the cover glass according to the set trajectory to obtain a cutting line;

[0038] S103, the transplanting robot moves the cover glass from the cutting station to the split station;

[0039] S104. Generate laser thermal stress at the cutting line of the cover glass according to the set trajectory, so that the cut cover glass is split under the action of the laser thermal stress.

[0040] Wherein, the cutting tool used when cutting and scribing the cover glass includes an infrared laser; the laser used when generating laser thermal stress at the cutting line of the cover glass is a carbon dioxide laser.

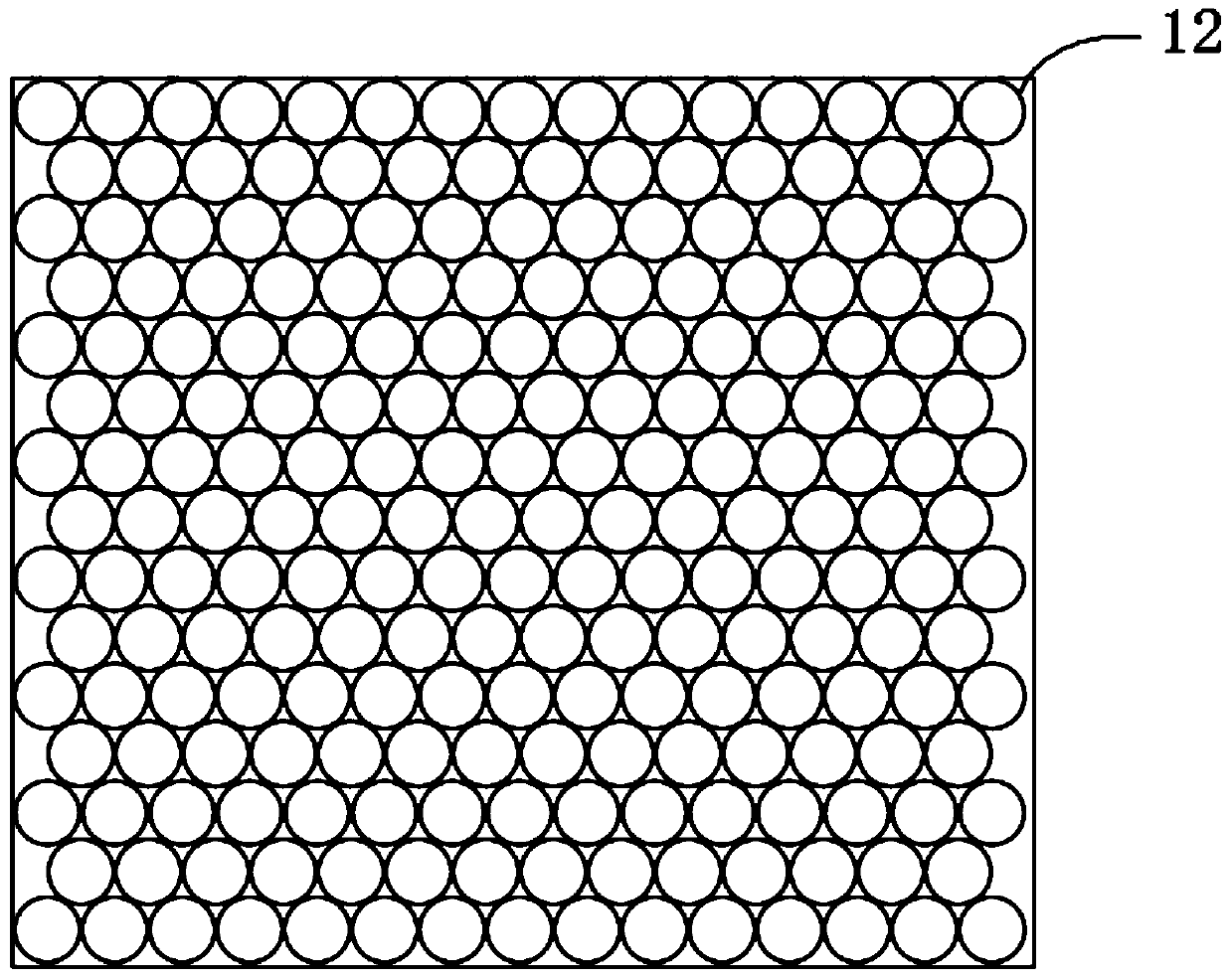

[0041] It should be noted that the cutting line 12 is the infrared laser scribing on the surface of the glass material, so that the glas...

Embodiment 2

[0055] Such as Figure 4 As shown, Embodiment 2 of the present invention provides a glass cutting splinter processing device, which specifically includes the following modules:

[0056] The carrier 20 is used to carry the cover glass to be processed, and realize the five-point positioning of the cover glass at the cutting station;

[0057] The cutting and scribing module 21 is arranged at the front end of the carrier in the conveying direction and above the cover glass, for generating laser light, and cutting and scribing the cover glass according to a set trajectory to obtain a cutting line ;

[0058] The splinter module 22 is arranged at the rear end of the cutting device, and is used to generate laser light, and generate laser thermal stress at the cutting line of the cover glass according to the set trajectory, so that the cut cover glass is under the action of laser thermal stress. lobes.

[0059] Preferably, the cutting tool used when cutting and marking the cover gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com