Reliability test device for CNC (Computer Numerical Control) grinding machine

A feed system, CNC grinding machine technology, applied in the direction of measuring devices, machine/structural components testing, instruments, etc., can solve the problem that the reliability of the CNC grinding machine feed system has few basic data, few reliability loading tests, and can not grasp the numerical control. Grinder feed system reliability level and other issues, to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

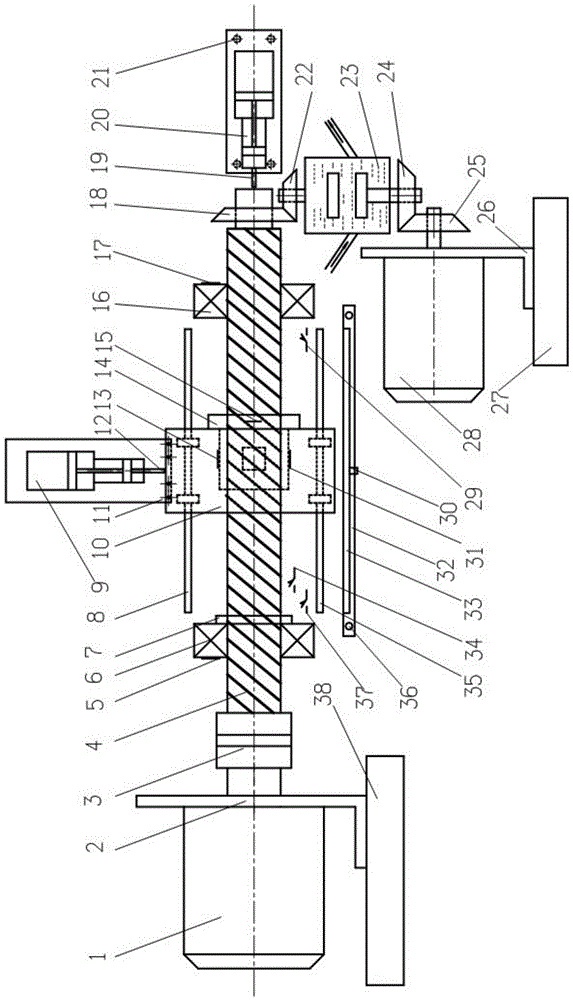

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

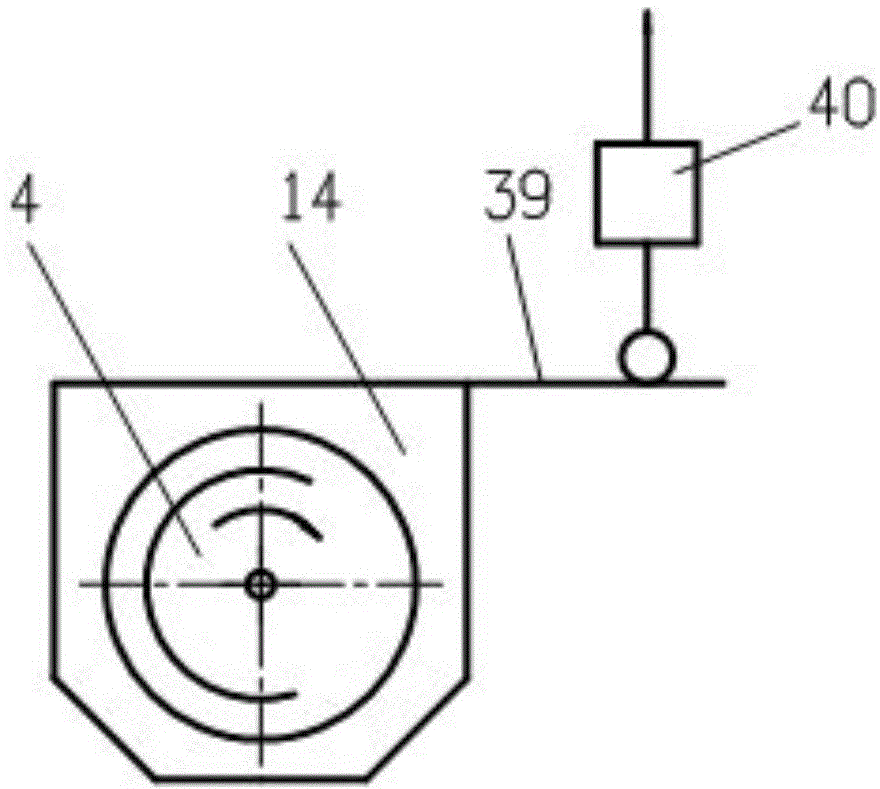

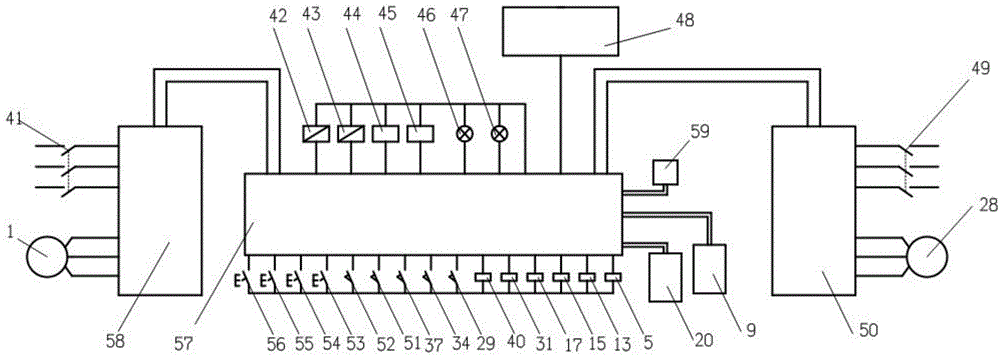

[0029] figure 1 It is the schematic diagram of the mechanical structure of the test device. The servo motor a (1) drives the screw (4) to rotate, the screw (4) drives the worktable (10) to move, and the guide rail a (8) and the guide rail b (35) align (10) Play a guiding role. pass image 3 The programmable controller (57) in the control servo driver b (58) to change the rotation speed of the servo motor (1), thereby simulating the different speeds of the CNC grinding machine during processing. The servo motor b (28) realizes the grinding torque loading on the lead screw (4) by driving the hydraulic coupling (23) to run. pass image 3 The programmable controller (57) in the control servo driver a (50) to change the rotation speed of the servo motor (28), thereby simulating the different grinding torques of the CNC grinding machine during processing. pass image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com