Five-axis linkage numerical control grinding knife machine tool

A five-axis linkage and machine tool technology, which is applied to the parts of the grinding machine tool, the control of the workpiece feed movement, and the grinding frame, etc., can solve the problems of operator safety hazards, labor intensity, difficult coordination of movements, and low processing efficiency. , to achieve the effect of improving machining accuracy and service life, ensuring machining accuracy, and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

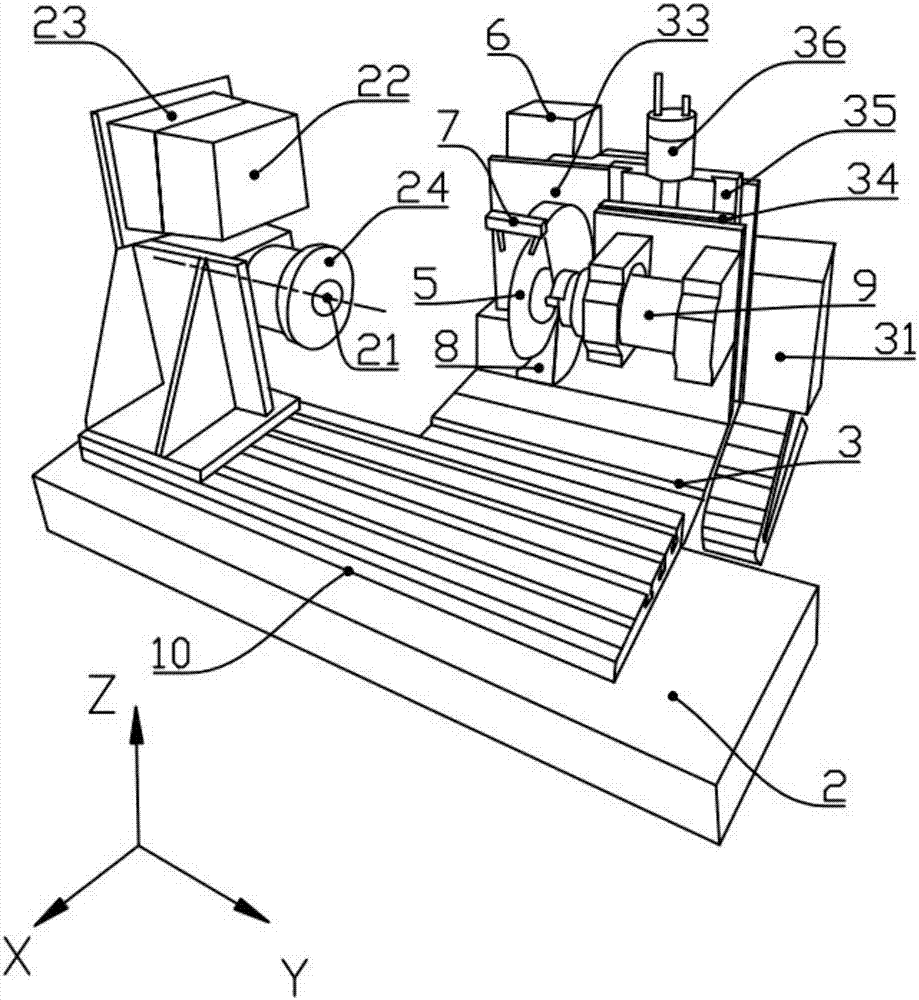

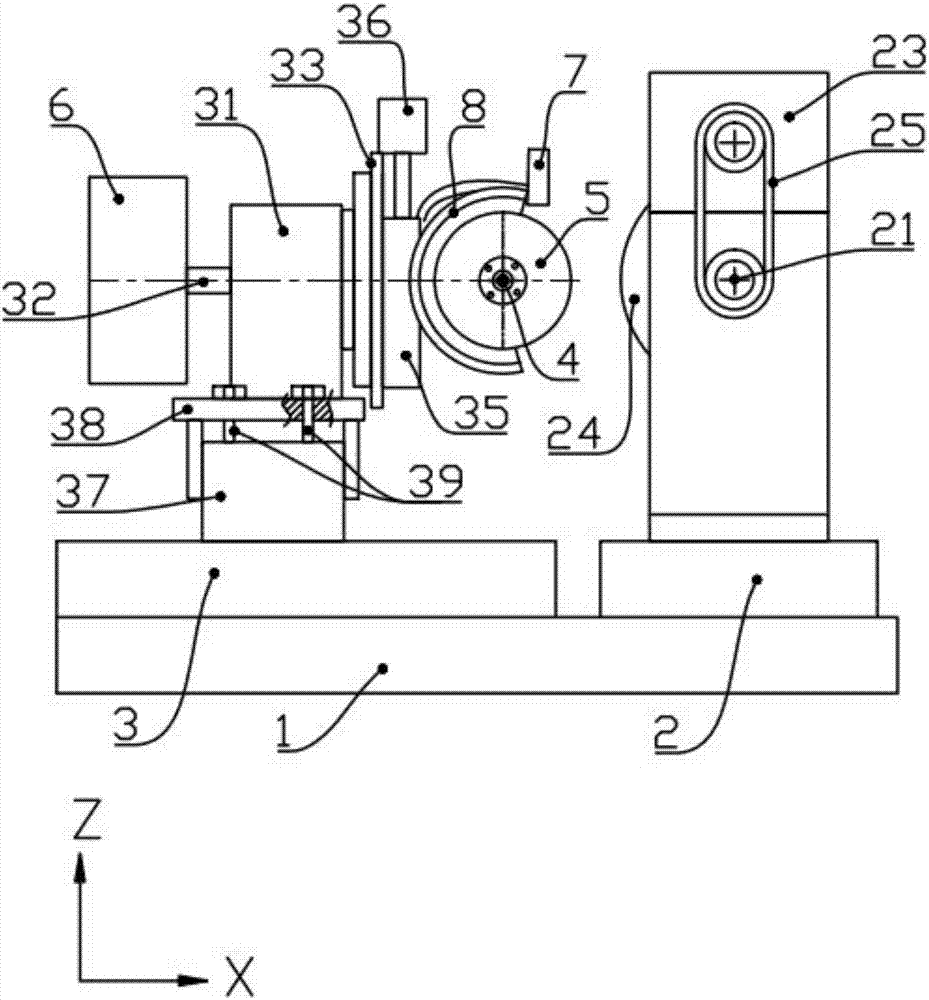

[0042] The present invention defines the following concepts:

[0043] The axis of the workpiece axis is the axis A;

[0044] The spindle axis is axis B;

[0045] The axis of the rotating shaft is the axis C;

[0046] The grinding point of the tool and the grinding wheel is the working point D.

[0047] The following specific examples further describe the present invention:

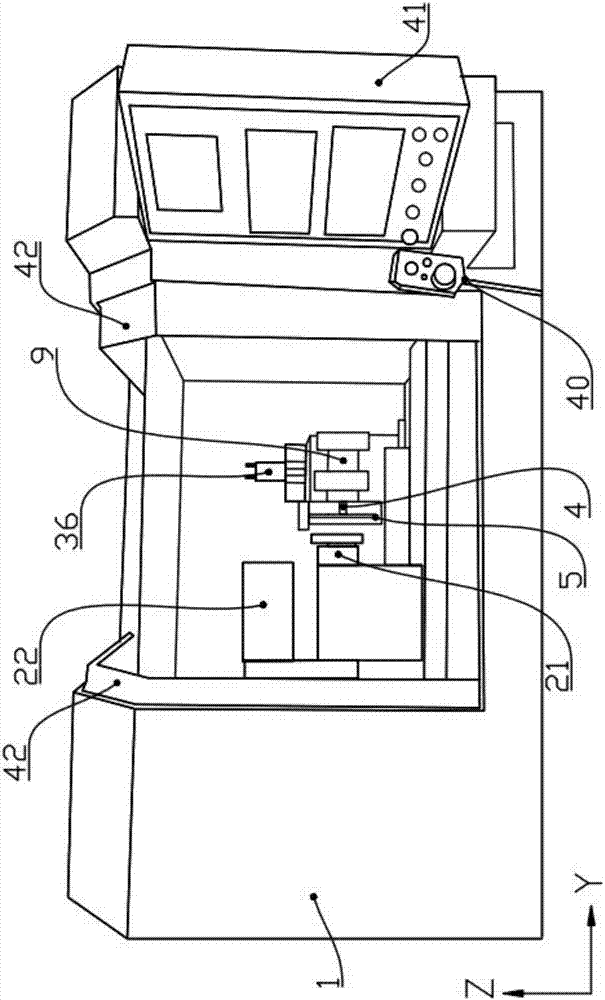

[0048] A five-axis linkage CNC knife sharpening machine tool, comprising a frame 1, the frame 1 is provided with a worktable 2 and a spindle table 3 whose motion directions are perpendicular to each other, and the worktable 2 performs axial feed motion along the Y axis, The headstock 3 makes an axial feed motion along the X axis.

[0049] The workbench 2 is fixedly provided with a mounting table 10, and a power chuck is installed on the mounting table 10. The power chuck includes a workpiece shaft 21. The workpiece shaft 21 is arranged along the Y-axis direction, and the workpiece shaft 21 is set throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com