Eccentricity adjusting method and device for vertical numerically controlled grinder to process eccentric orifice

A technology of numerical control grinding machine and adjustment method, which is applied in grinding machines, metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of high processing cost, high precision requirements, complex structure, etc. The effect of ensuring grinding accuracy and efficiency and simplifying the process of clamping workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

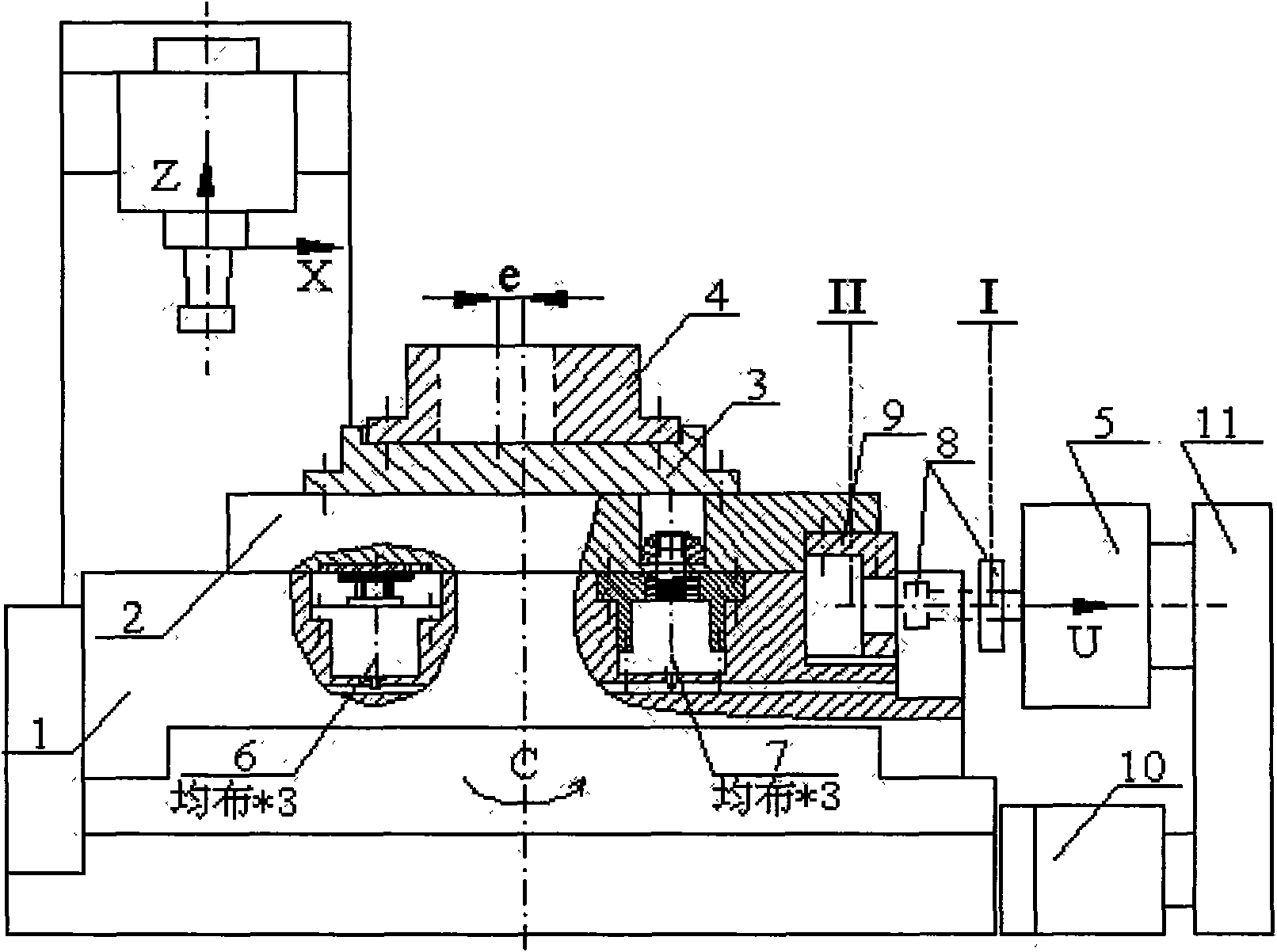

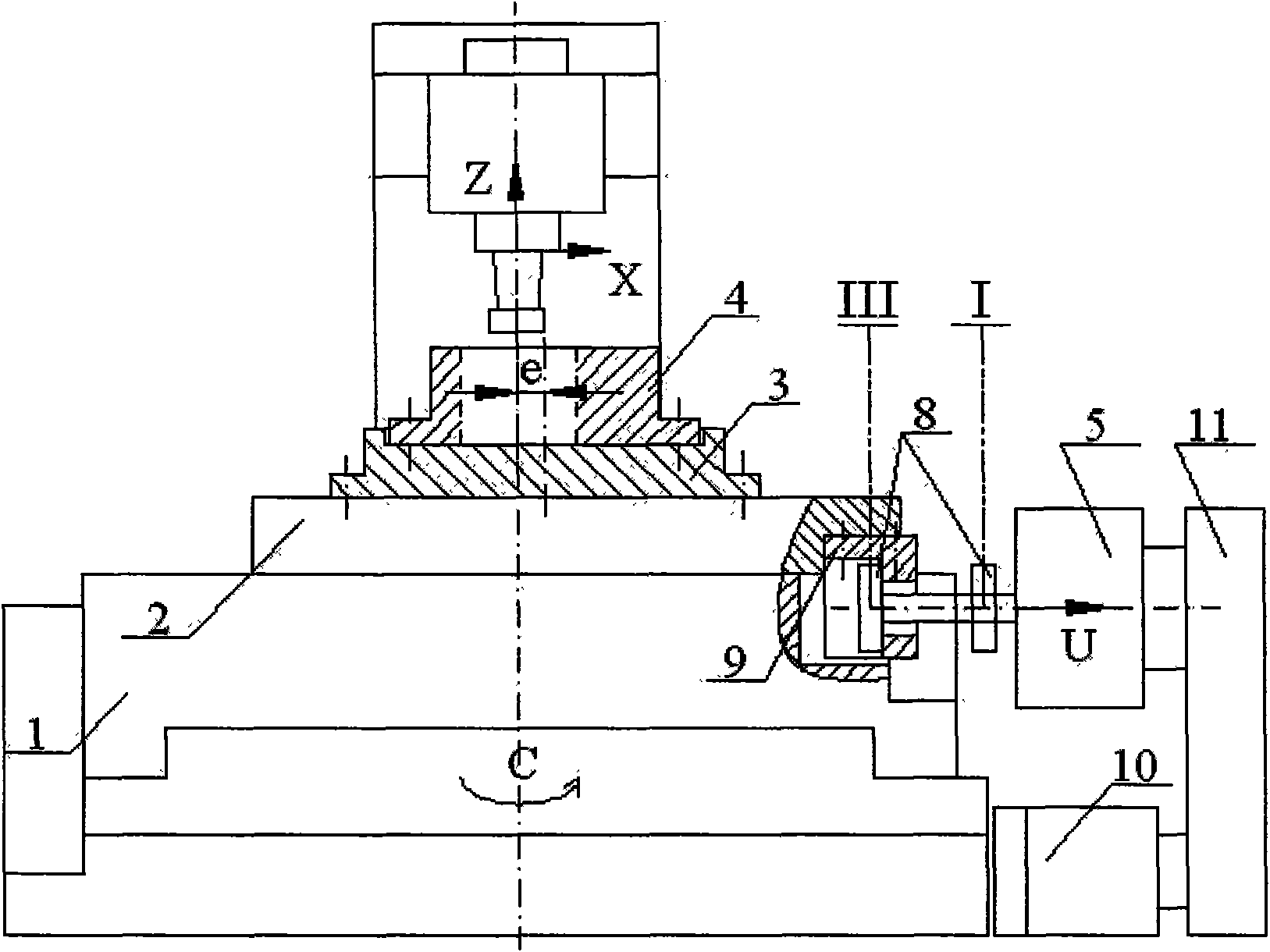

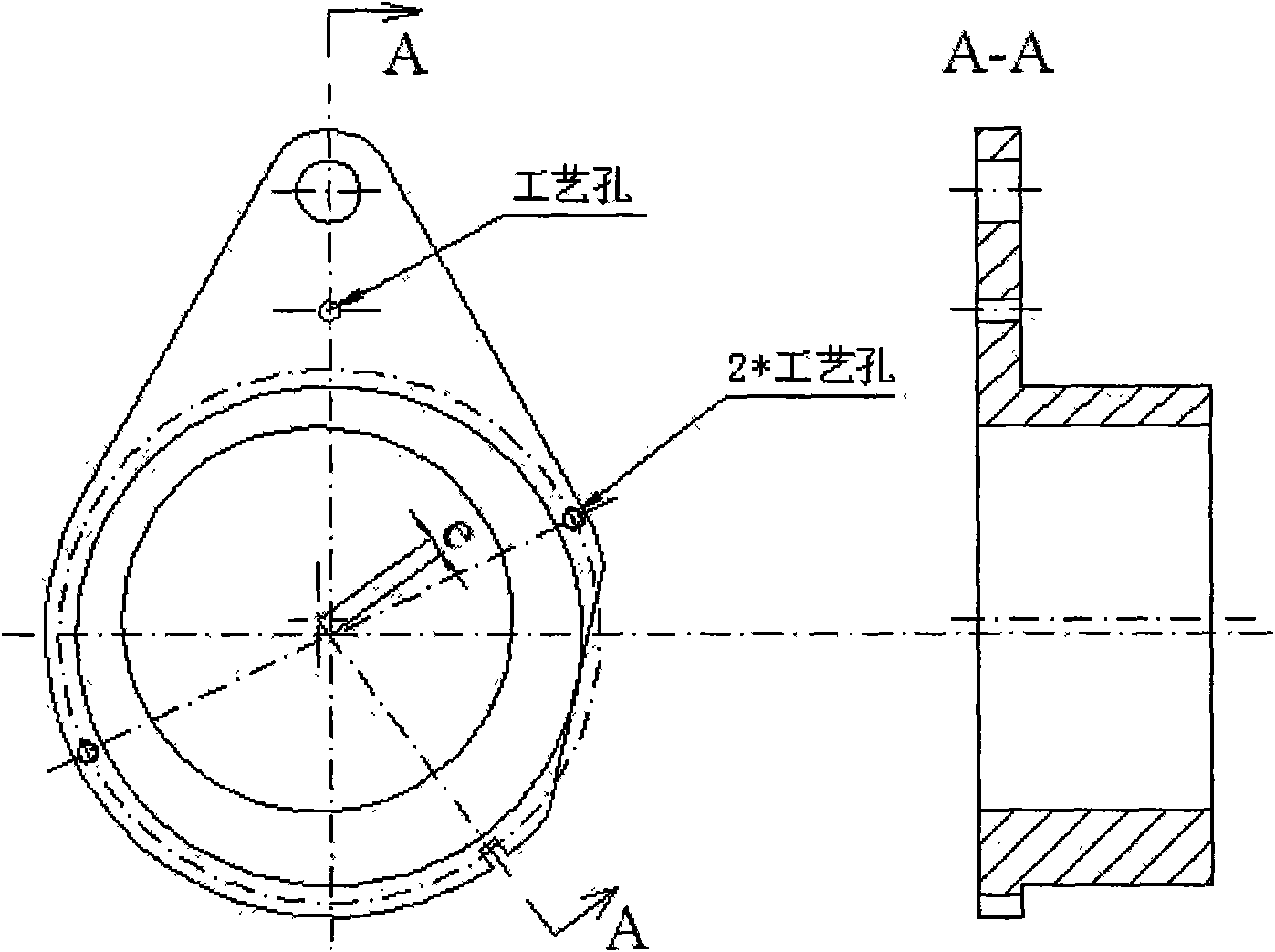

[0032] by image 3 The typical workpiece shown --- large eccentricity bearing is taken as an example, and the embodiment of the present invention is described below:

[0033] see image 3 and Figure 4 , the method of adjusting the eccentricity of the eccentric hole processed by the vertical grinding machine is as follows: firstly, install the eccentric bearing on the auxiliary tooling, and then fasten it as a whole on the workbench 2, and make the eccentric direction line O through the positioning of the auxiliary tooling 1 o 2 Parallel to the center line of the rectangular stepped hole of the pull block 9. Then, through the numerical control system to control the relevant movement of the drive shaft C and auxiliary shaft U of the workbench 2, and cooperate with a series of auxiliary commands or panel buttons of the numerical control system, the programmable logic controller PLC controls the actions of each cylinder, and completes the following adjustment steps in sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com