A mixing and extruding device for raw materials for sealing ring production

A technology of extrusion device and sealing ring, which is applied in the field of mixing and extruding device for producing raw materials for sealing ring, can solve the problems of long mixing time, single mixing direction, and inability to guarantee the uniformity of raw materials and auxiliary materials, and achieves a high degree of mixing, Improve the mixing effect and the mixing effect of raw materials is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

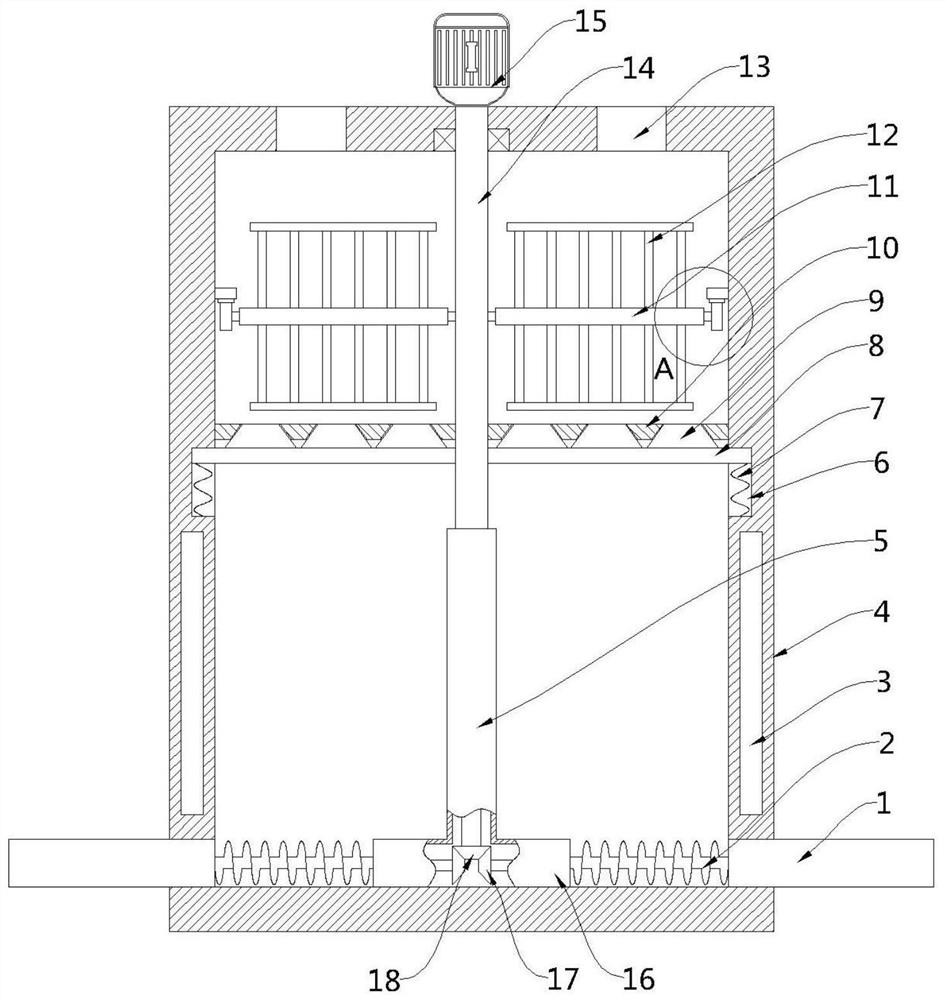

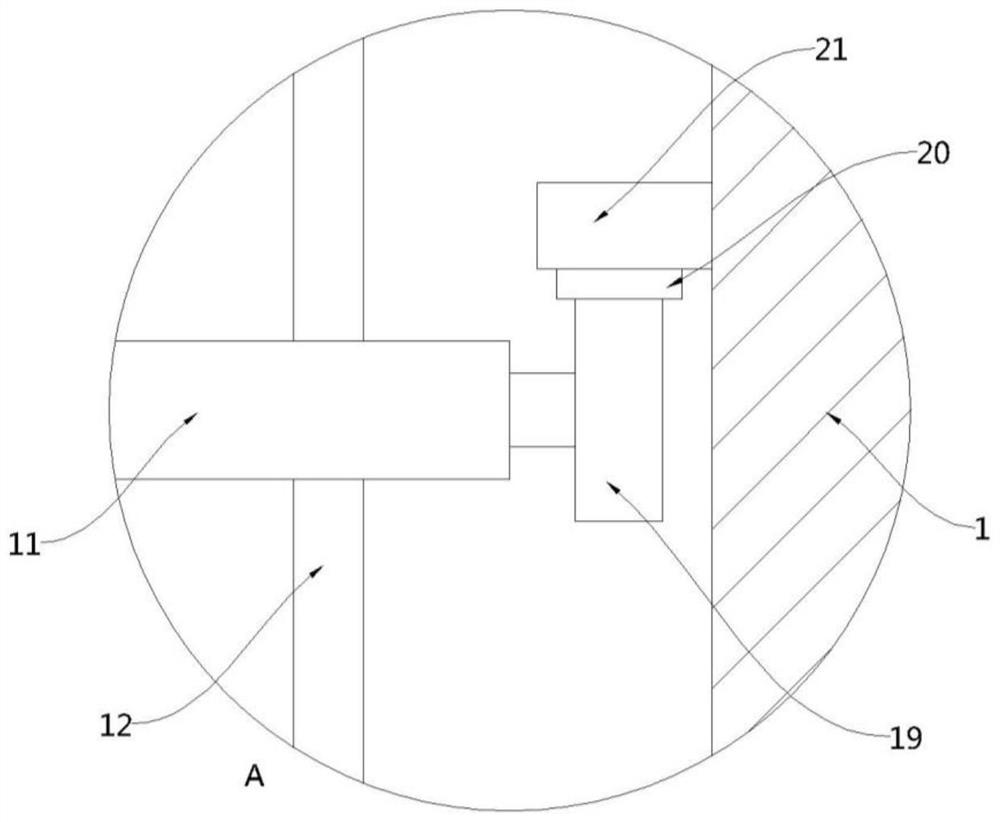

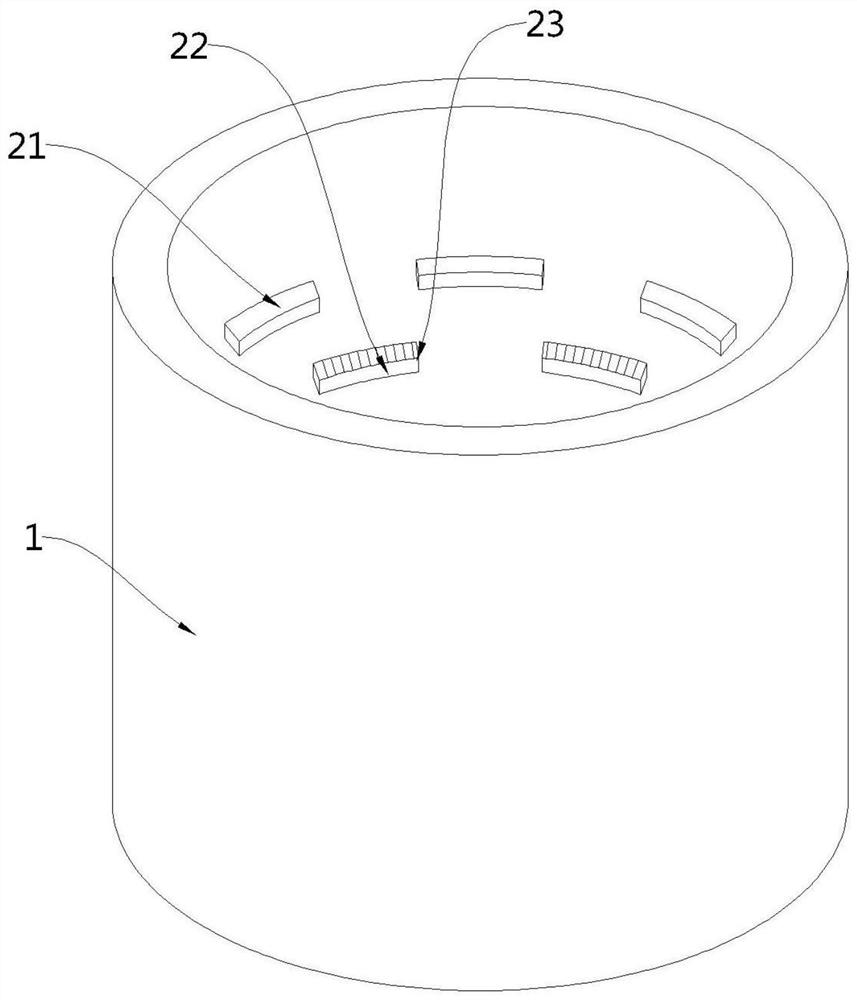

[0024] see Figure 1-3 , this embodiment provides a mixing and extrusion device for producing raw materials for sealing rings, including a barrel 4, a partition 10 is arranged inside the barrel 4, and a feed port 13 is opened on the top of the barrel 4, and the partition 10 A mixing area is provided above, a heating area is provided below the partition 10, a stirring assembly is provided inside the mixing area, a heating assembly 3 is provided on the inner wall of the heating area, and an extruding assembly is provided at the bottom of the heating area, specifically, The stirring assembly includes a vertical drive shaft 14 and a number of stirring columns 11 that are rotatably mounted on the side wall of the drive shaft 14 and extend horizontally. The upper end of the drive shaft 14 extends to the outside of the barrel 4 and is fixedly connected with a motor 15, the side wall of the stirring column 11 is provided with a number of stirring rods 12, the end of the stirring colum...

Embodiment 2

[0037] see figure 1 , a raw material mixing and extrusion device for sealing ring production. Compared with the embodiment, the bottom of the heating zone is also provided with a horizontal protective cylinder 16 and is arranged on the upper part of the horizontal protective cylinder 16 and connected with the horizontal protective cylinder. The cylinder 16 is connected to the vertical protective cylinder 5, the lower end of the drive shaft 14 extends to the inside of the vertical protective cylinder 5 and is fixedly connected with the first helical gear 18, and the extrusion screw 2 is located in the heating zone One end inside extends to the inside of the horizontal protective cylinder 16 and is fixedly connected with the second helical gear 17 .

[0038] The drive shaft 14, the first helical gear 18 and the second helical gear 17 are protected by the vertical protection cylinder 5 and the horizontal protection cylinder 16, which can relatively reduce the impact of molten raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com