Spherical surface machining method

A spherical processing and to-be-processed technology, applied in the field of mechanical parts processing, can solve the problems of high processing cost, difficult repair, and high profile requirements, and achieve the effects of reducing processing costs, simplifying processing procedures, and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

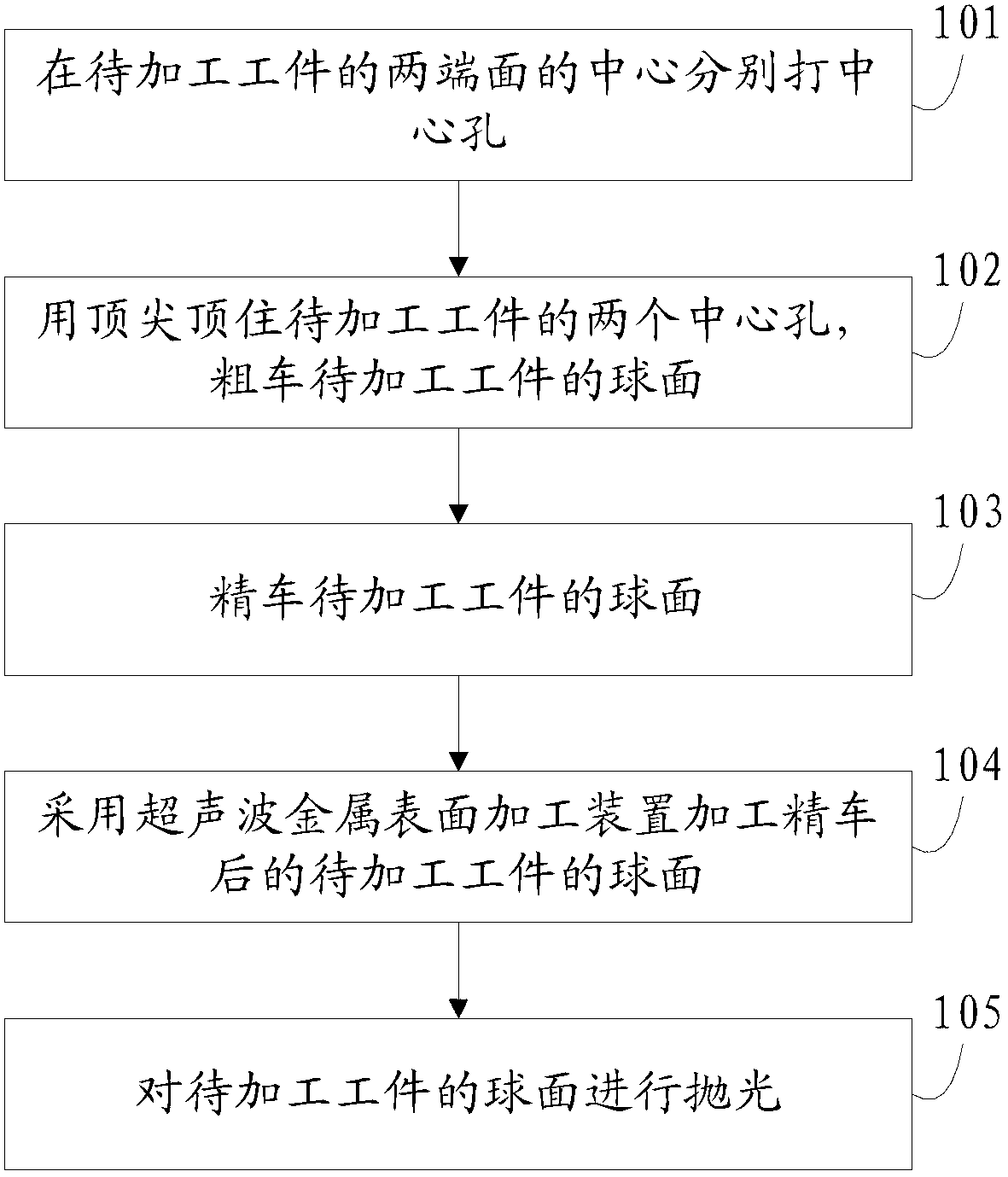

[0039] Combine below figure 1 The method is described in detail as figure 1 As shown, the method includes:

[0040] Step 101: Drilling center holes at the centers of the two end surfaces of the workpiece to be processed, the above-mentioned end surfaces being perpendicular to the center line of the workpiece to be processed.

[0041] Place the workpiece to be processed on the rotary table of the boring machine, fix the workpiece to be processed, and punch a center hole in the center of the end face.

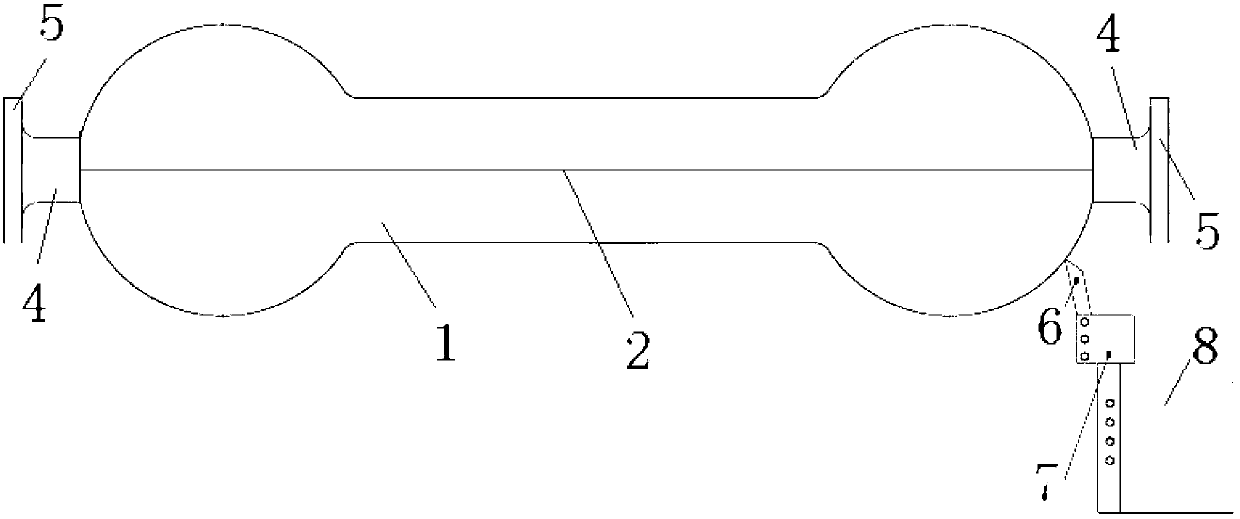

[0042] Take the processing of the two spherical surfaces of the hinge shaft as an example, see figure 2 , draw a cross line on the end face of the hinge shaft, and the intersection point of the cross line is the center of the end face. Specifically, draw the waistline 2 of the hinge shaft 1 first, lead the waistline 2 to the two end surfaces 3, and then draw a vertical line on the straight line leading to the end surfaces 3.

[0043] Before marking, use vernier caliper, micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com