Numerical control grinding machine

A CNC grinding machine and CNC system technology, applied in the direction of grinding machines, grinding bed, grinding machine parts, etc., can solve the problems of excessive dust, many adjustment elements, and low manual indexing accuracy of the universal dividing head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

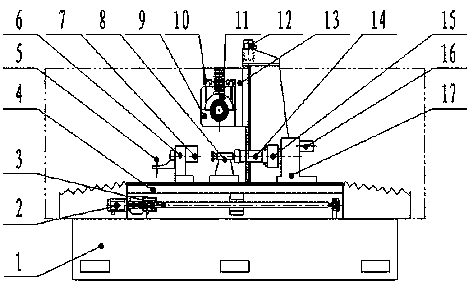

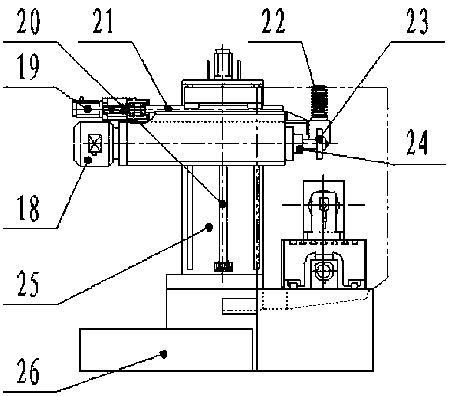

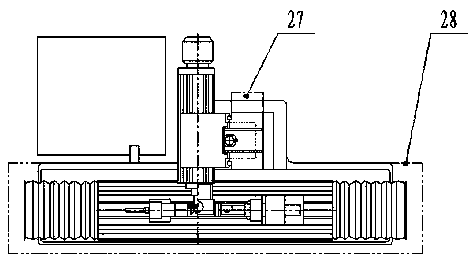

[0016] like figure 1 , figure 2 , image 3 Shown, the mechanical part of the present invention is made of bed 1, column 25, grinding head frame 13, tailstock 8, grinding head 9, workbench 4, emery wheel dresser 6, indexing mechanism 17 and claw chuck 15, sand Wheel shaft 24, exhaust dust removal system 27, semi-enclosed shield 28, cooling circulation system 26 and other components. A column 25 is fixedly installed on the bed 1, and the column 25 is connected with the grinding head frame 13 through the rolling linear guide rail and the ball screw rod 20; the grinding head frame 13 is connected with the grinding head 9 through the rolling linear guide rail 10 and the ball screw rod 1 21; The grinding wheel shaft 24 is installed in the head 9, and is connected to the grinding wheel 23 through the grinding wheel shaft 24. The grinding wheel shaft 24 is driven by the grinding head motor 18 to drive the grinding wheel 23 to do the main cutting movement; It is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com