Spindle transmission component of CNC grinding (milling) groove machine tool

A technology for machine tool spindles and transmission components, applied to metal processing machinery parts, driving devices, metal processing equipment, etc., can solve the problems of easy wear of parts, easy wear of tracks, poor indexing accuracy, etc., to achieve convenient manufacturing and installation, and guarantee Machining accuracy and the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

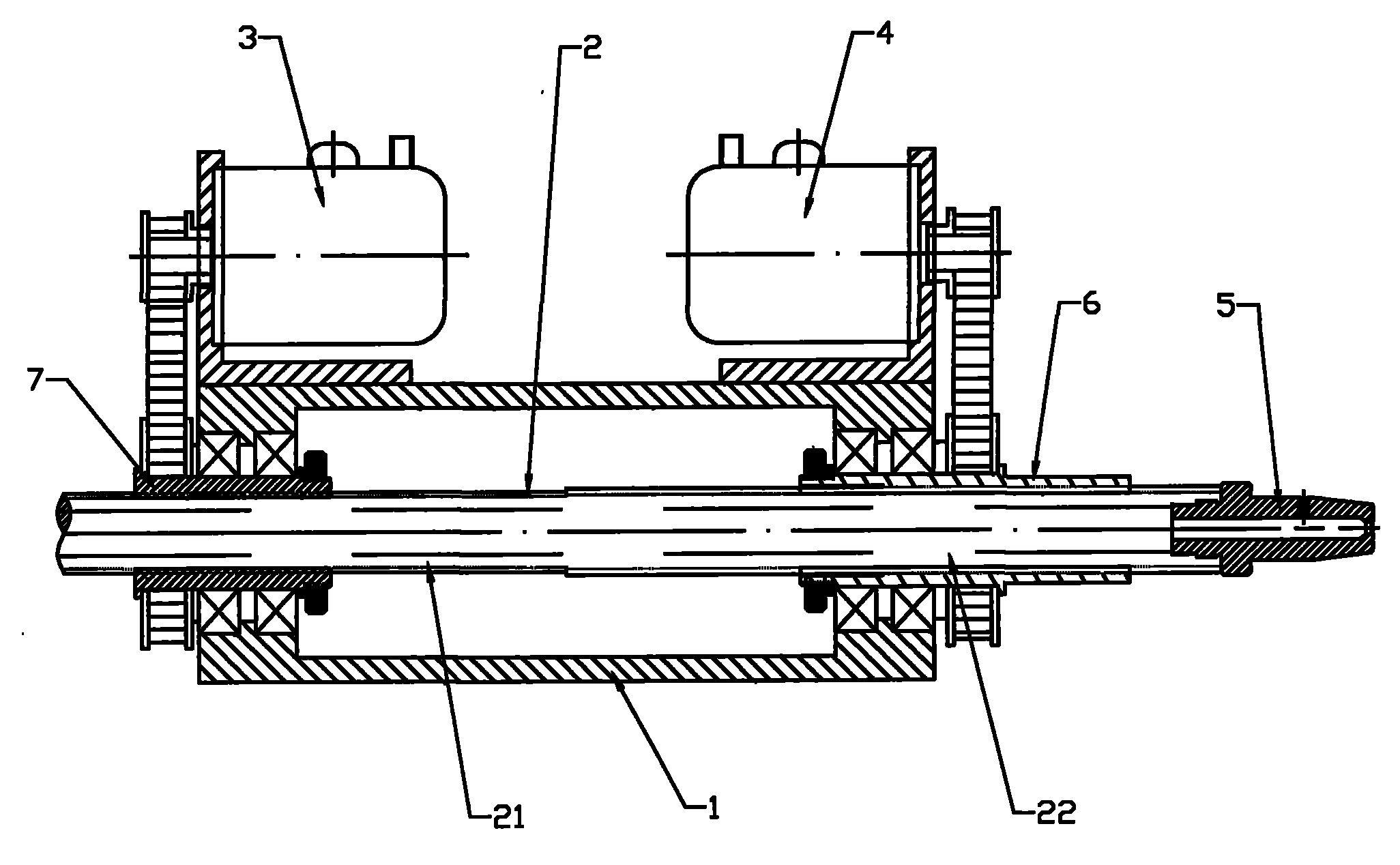

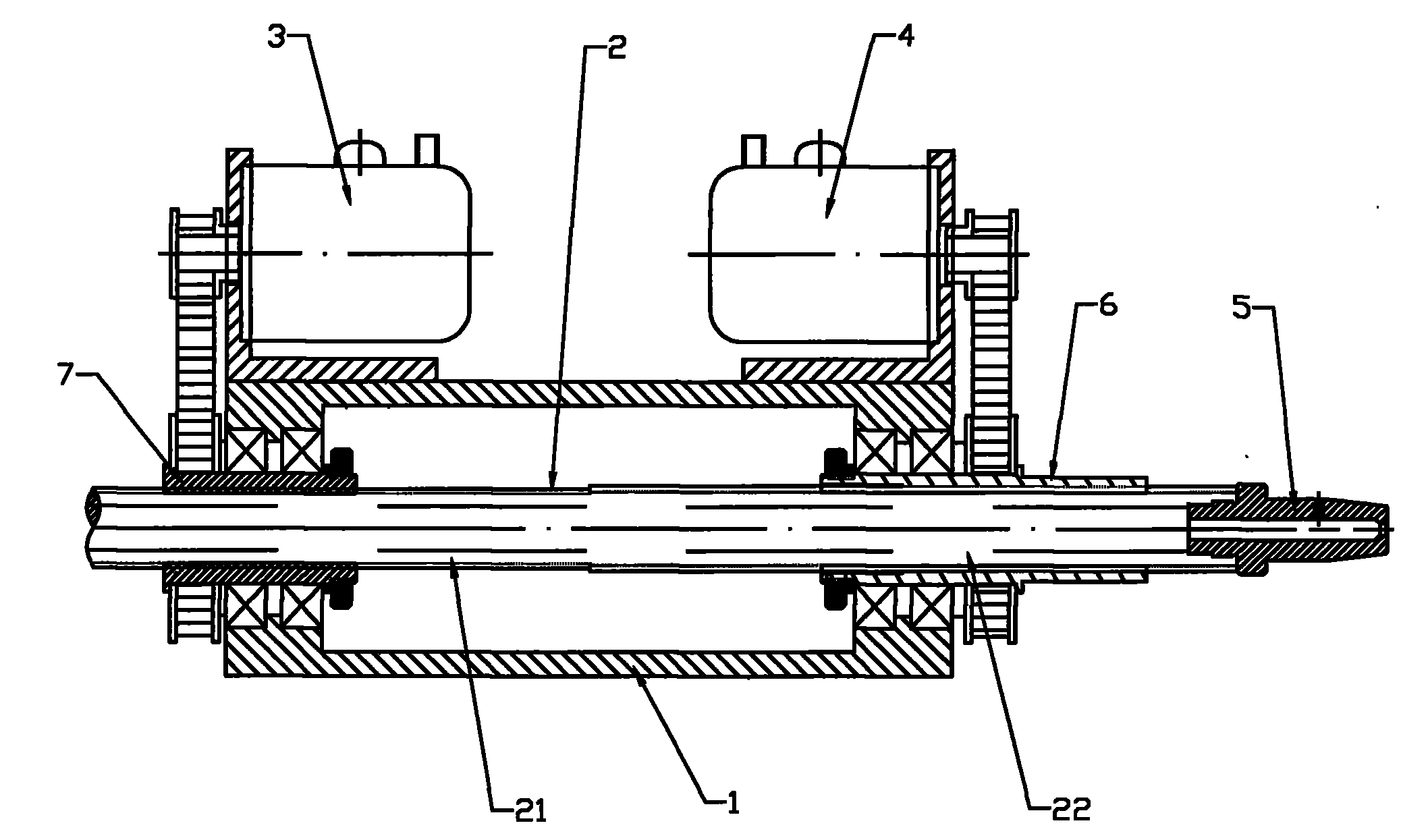

[0010] As shown in the figure, the spindle transmission components include a fixed box 1, a spindle 2, a linear feed CNC motor 3, and a rotary indexing CNC motor 4; the front end of the spindle 2 is equipped with a chuck 5 for clamping the workpiece; the spindle is divided into There are two coaxial front and rear sections; the front section of the main shaft is a spline shaft 21, and the spline shaft is covered with a spline sleeve 6, the main shaft can rotate with the spline sleeve and slide back and forth relative to the spline sleeve, and the spline sleeve 6 passes through The bearing is installed on the fixed box 1 and can be driven by the rotary indexing numerical control motor 4; It is installed on the fixed box 1 through bearings and driven by a linear feed numerical control motor 3 . The splined shaft 21 and the lead screw 22 that make up the main shaft 2 can be processed on one integral shaft, or can be processed separately by two shafts and then fixedly connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com