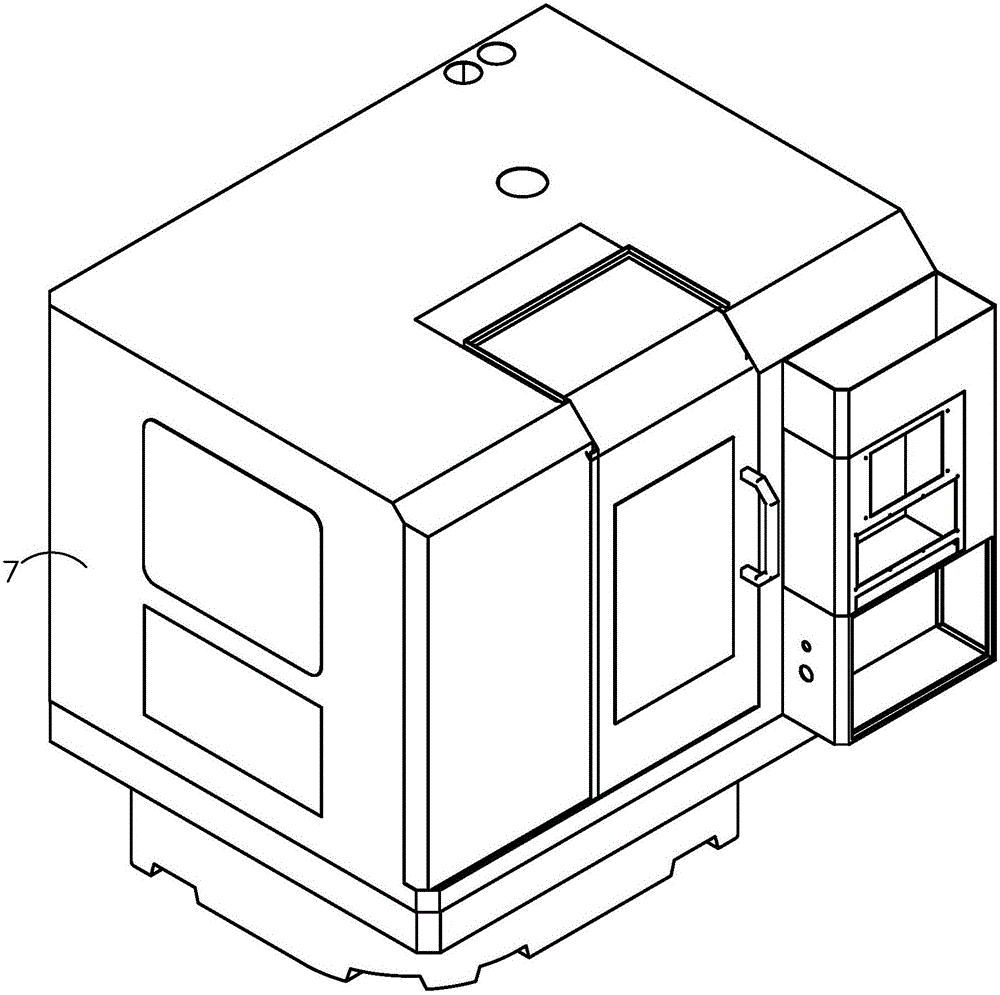

Five-axis CNC grinding robot

A robot and Z-axis technology, applied in the direction of grinding frame, grinding machine parts, grinding machine, etc., can solve problems such as interference, inability to process tool products, troublesome operation, etc., and achieve good rigidity, not easy to loosen, and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

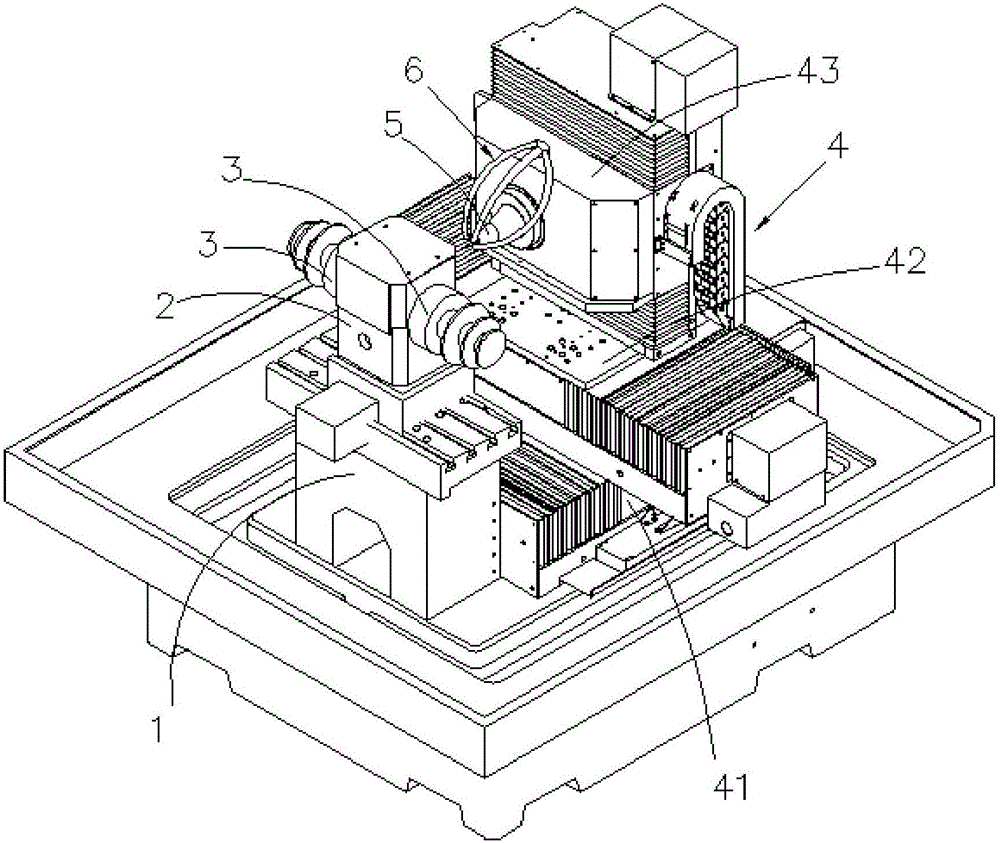

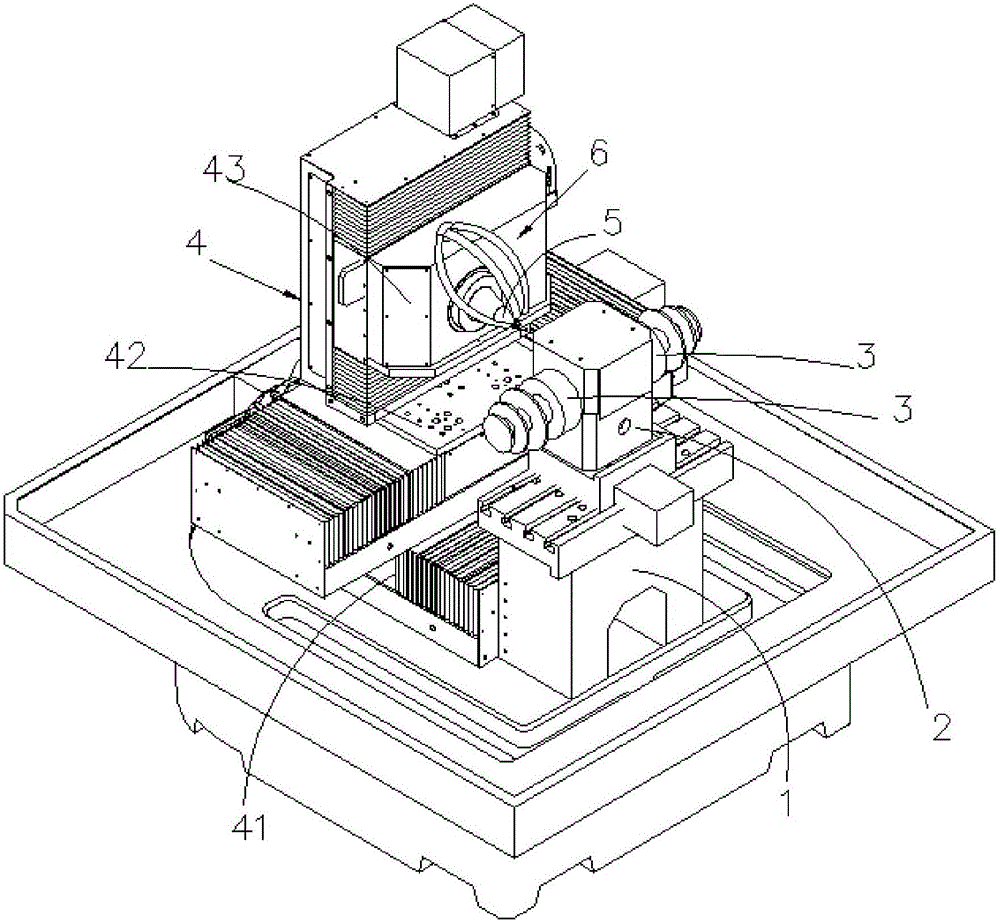

[0020] As shown in the attached drawings, a five-axis CNC grinding robot , include , base 1, Rotate along the vertical axis connected to the base 1 processing seat 2, swivel connection on the processing seat 2 Machining spindle with axis line extending horizontally 3, set on the base 1 workpiece transfer mechanism 4, Set on the workpiece transfer mechanism 4 Workpiece Loading Section on 5, and program control mechanism. the base 1 It is made of marble, with good rigidity and stability, no thermal deformation, and high processing precision.

[0021] The processing spindle head 3 There are at least two, which are respectively used to install the grinding wheel so as to be installed on the workpiece loading part 5 The workpiece on the machine is ground. In this embodiment, the machining spindle head 3 There are two, which are oppositely arranged on the two sides of the rotating seat. The processing spindle head 3 axis coinci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com