Pneumatic flat pressing machine for sticking carton box

A flattening machine and air pressure technology, applied in the field of flattening machines, can solve the problems of uneven pressure at the bonding place of the carton, easy cracking at the bonding place of the carton, poor flattening effect of the carton, etc., so as to improve the uneven pressure and simple structure. , The effect of carton leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

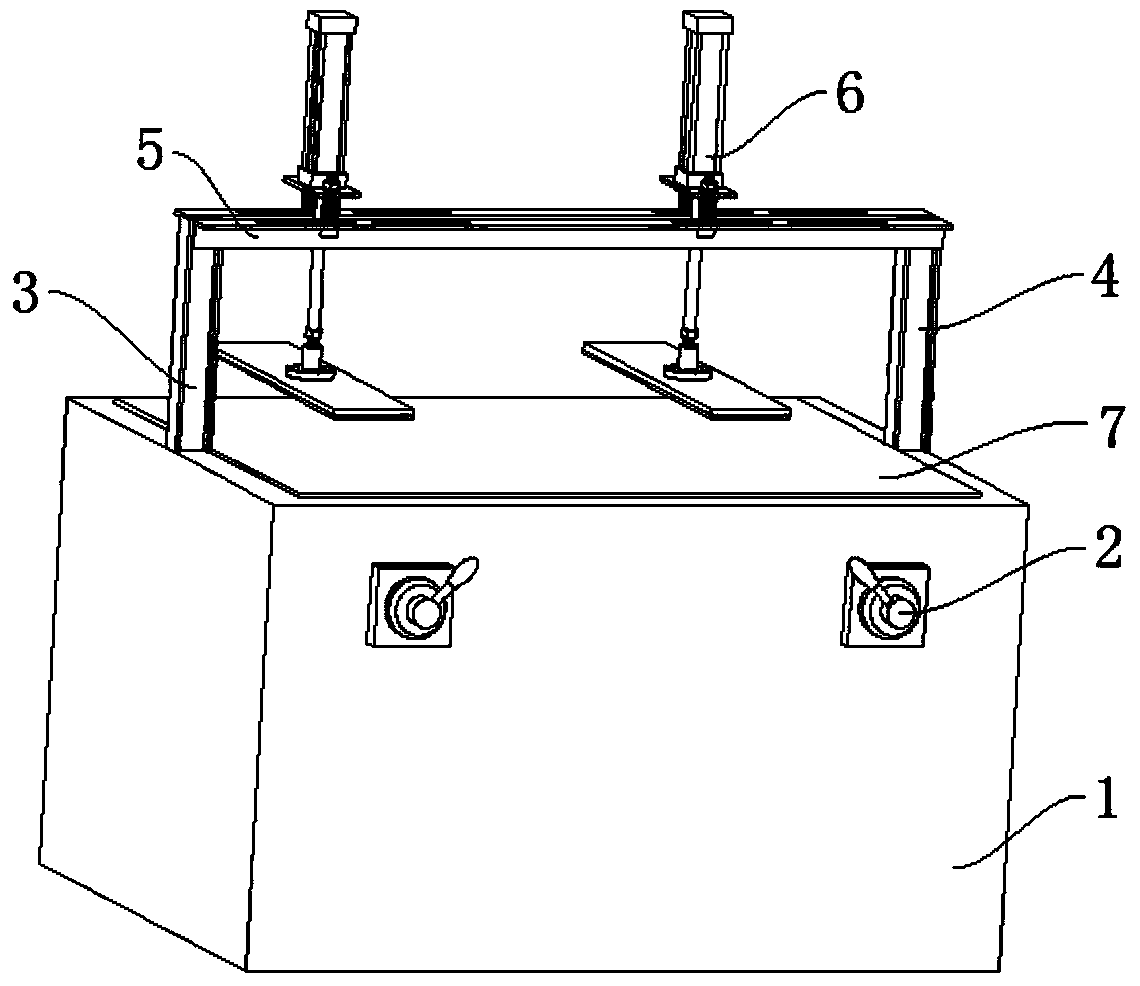

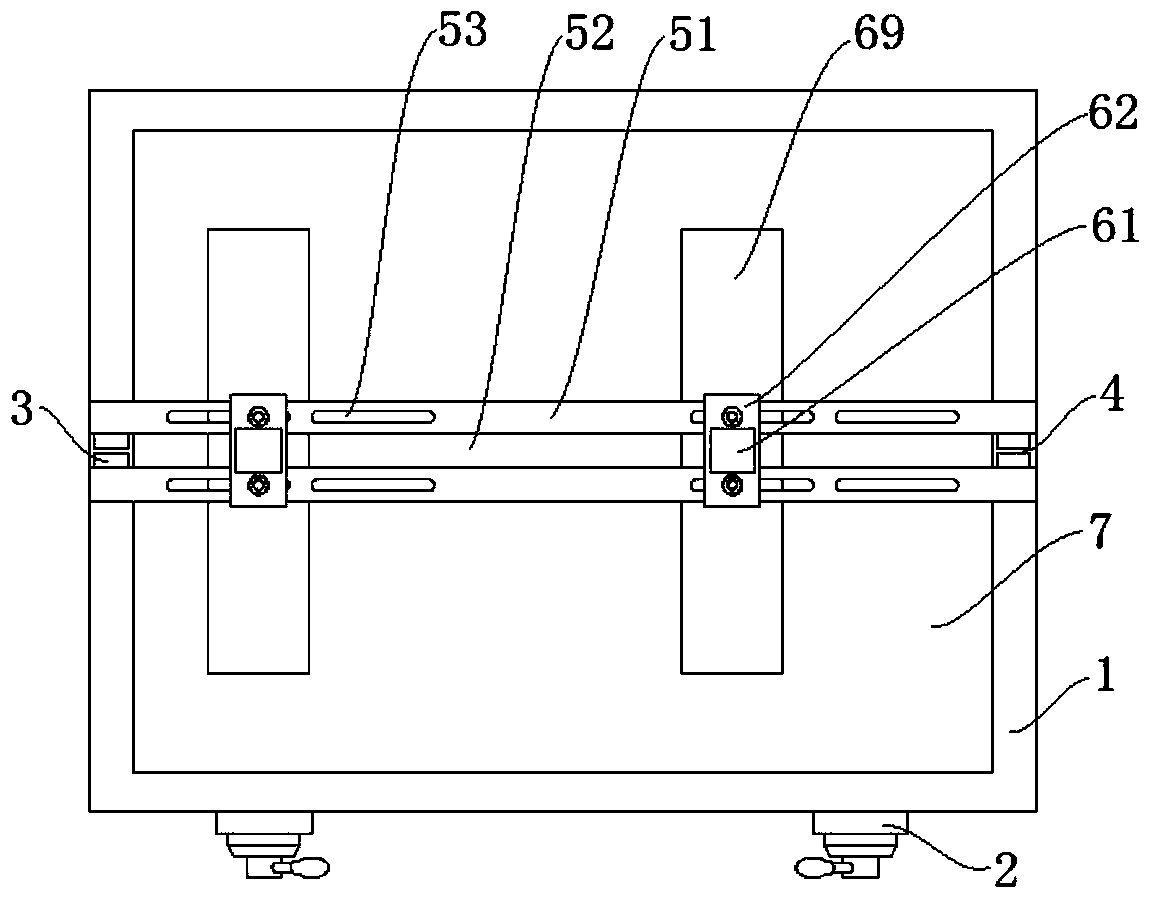

[0036] see figure 1, a carton pasting air pressure flattening machine of the present embodiment includes a pneumatic press 1, a first bracket 3 and a second bracket 4 arranged perpendicular to the working plane of the pneumatic press 1, and is fixedly connected to the first bracket 3 and the second bracket. The crossbeam 5 between the two supports 4 and the flattening mechanism 6 installed on the crossbeam 5 have simple structure, convenient operation, low cost and outstanding flattening effect. In order to prevent the force of the flattening mechanism 6 from directly acting on the working plane of the pneumatic press 1 and damaging the pneumatic press 1, a backing plate 7 is provided on the working plane of the pneumatic press 1. The backing plate 7 is easy to replace and easy to manufacture.

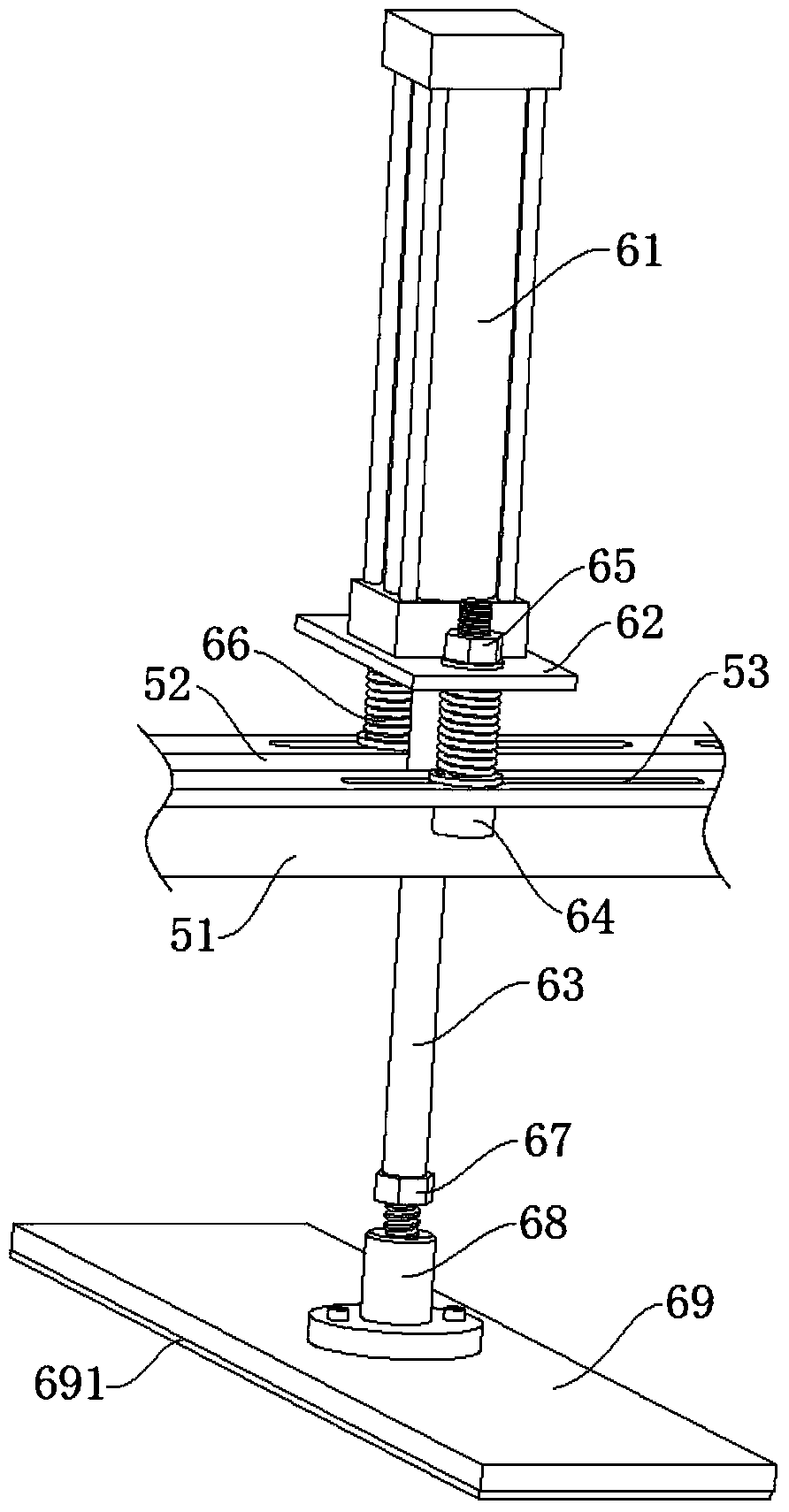

[0037] Among them, such as image 3 As shown, the flattening mechanism 6 includes a cylinder 61, a mounting plate 62, an adaptive tilting device, a pressing plate 69 and an air pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com