Lifting mechanism

A lifting mechanism and column technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of large guiding gap, low guiding accuracy, large working site, etc., and achieve the effect of safe and reliable land occupation, easy operation and small land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

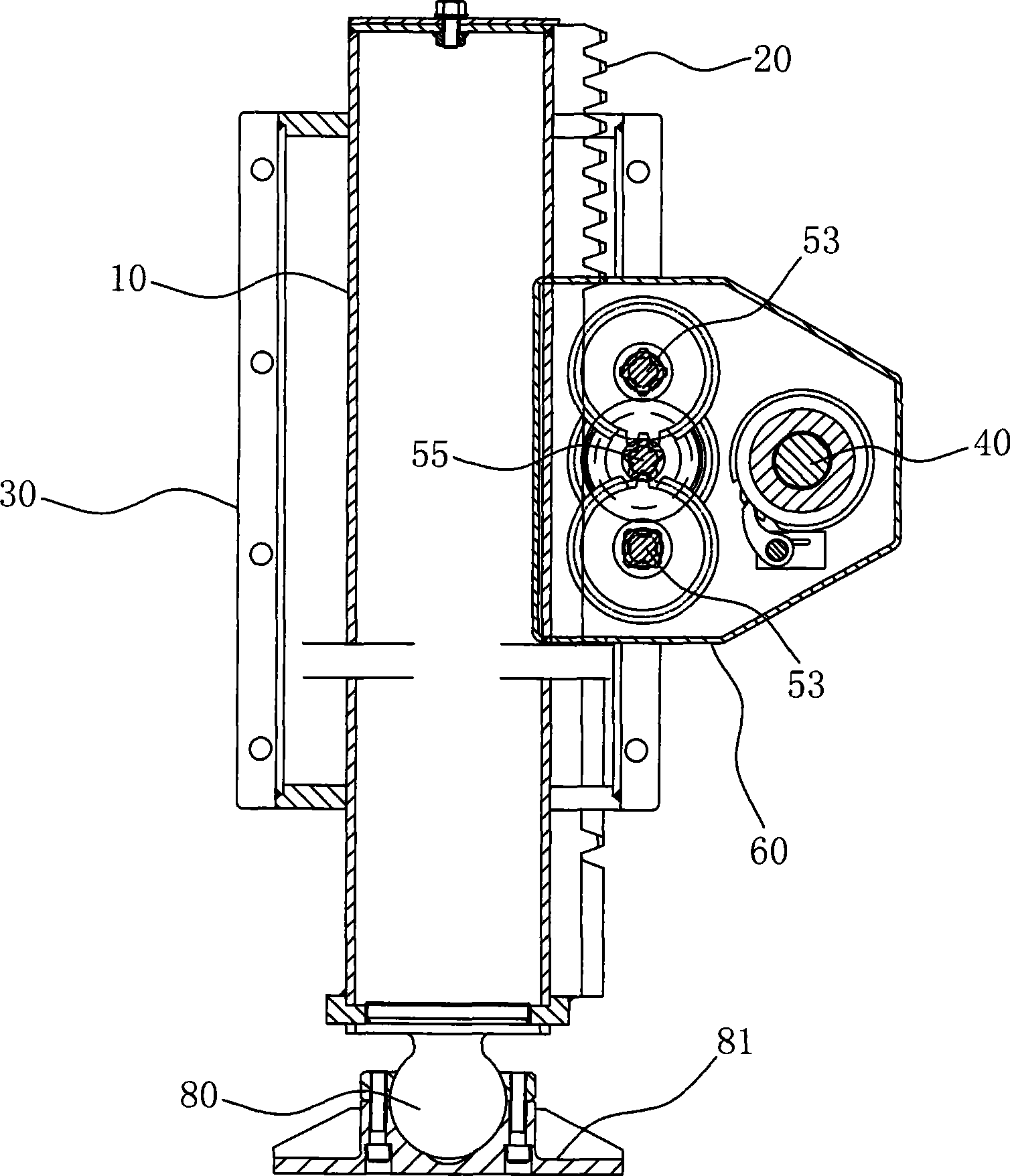

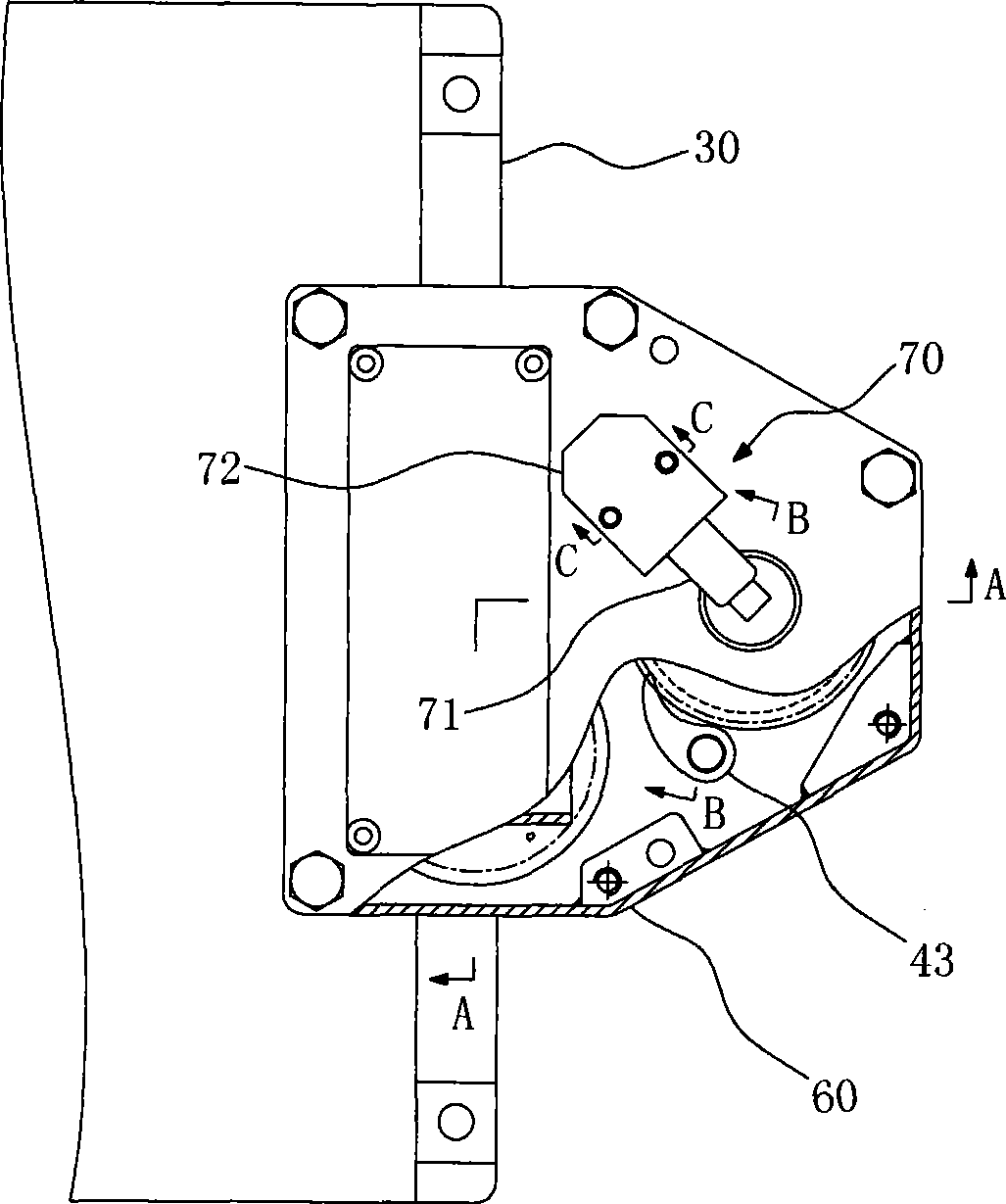

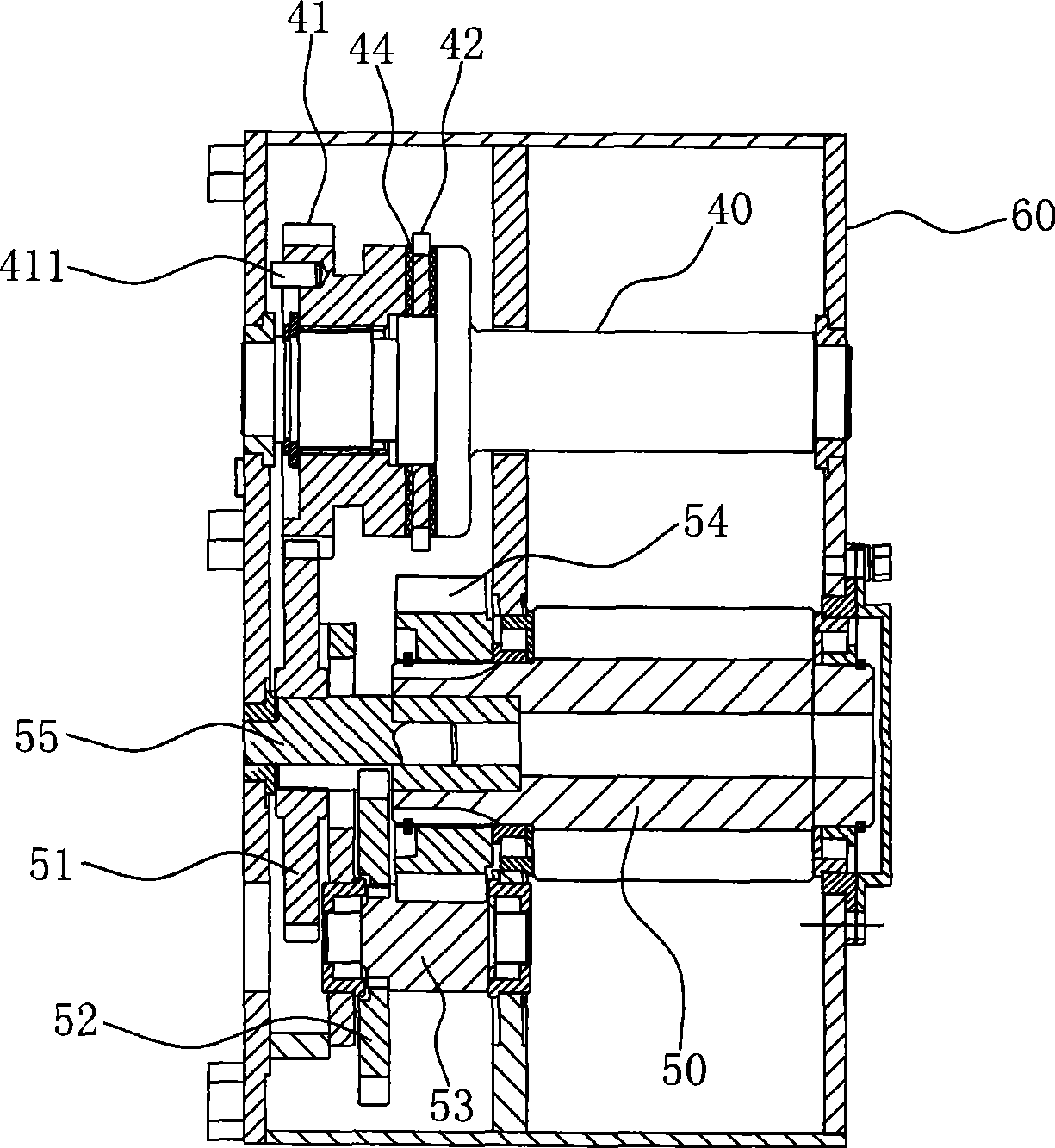

[0013] like figure 1 As shown, a lifting mechanism, the mechanism includes a column 10, the outer surface of the column 10 is provided with a rack 20, the direction of the rack 20 is parallel to the axial direction of the column 10, and the column 10 is also provided with a transmission device , the transmission device can move along the direction defined by the rack 20, and the bracket 30 is fixed on the transmission device.

[0014] In the present invention, the column 10 is used as a supporting member, and the rack 20, the transmission device and the bracket 30 are all attached to the column 10. Since the column 10 is used as a guiding element, the guiding precision is high. During work, work platforms such as containers and communication compartments are fixed on the support 30 , and the transmission drives the support 30 to move along the direction defined by the rack 20 , that is, to move along the set direction of the column 10 . From the above, it can be known that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com