Shutter tire roller tire graded conveyer device

A conveying device and series technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of low work efficiency, many actions, and heavy manual handling workload, so as to improve work efficiency and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

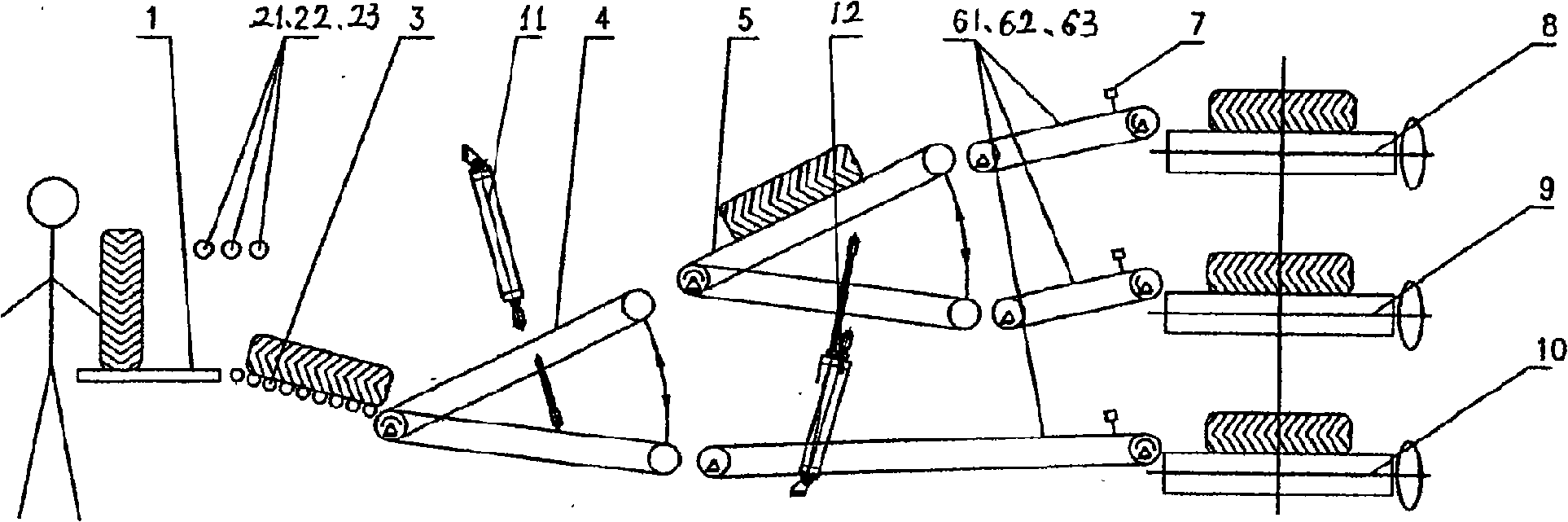

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

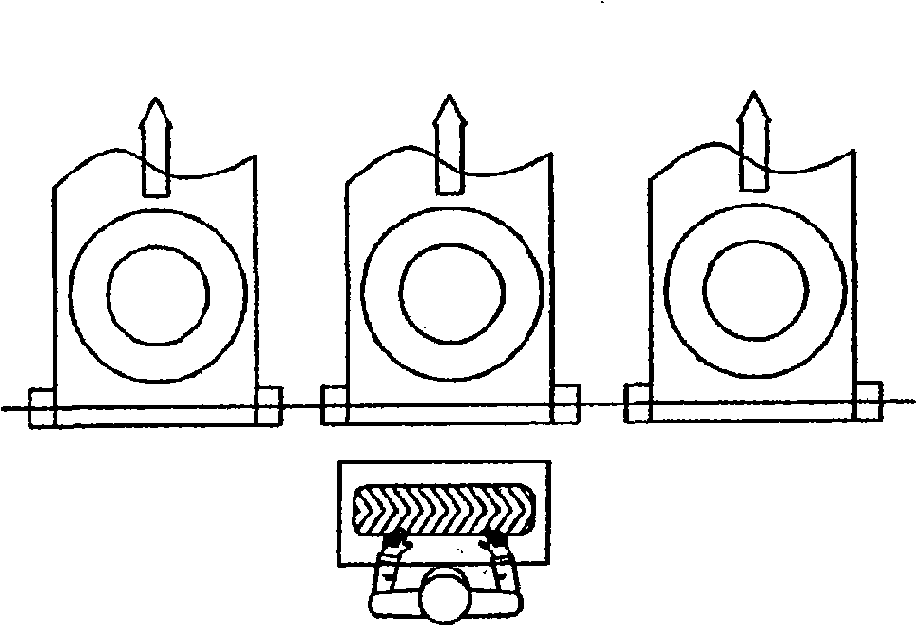

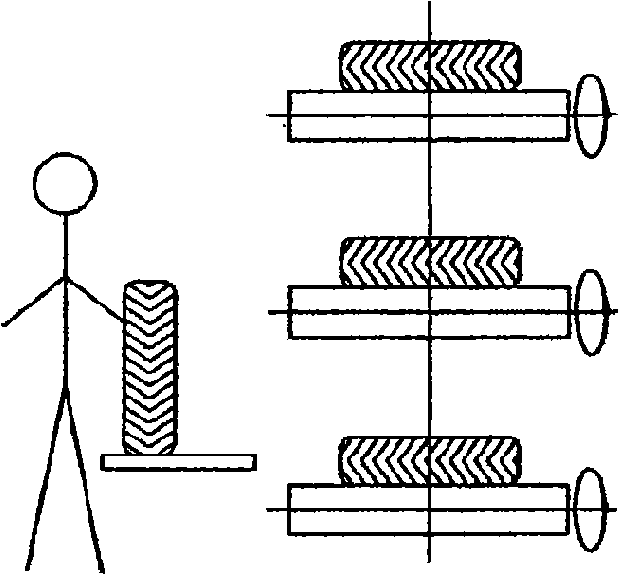

[0018] Such as image 3 As shown, the present invention is provided with an inspection table 1 and an upper grading conveyor belt 8, a middle grading conveyor belt 9, and a lower grading conveyor belt 10 arranged on the same vertical plane, and the front end of the inspection table 1 is equipped with a receiving roller inclined forward and downward Road 3, the receiving roller table 3 is composed of multiple free rollers arranged in parallel in the same plane, and the receiving roller table 3 is provided with a first-stage flap belt conveyor 4, a first-stage flap belt conveyor 4 and a first-stage hydraulic cylinder 11 The ends of the telescopic rods are connected, the first-stage flap belt conveyor 4 swings around its rear end under the push of the primary hydraulic cylinder 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com