Cam profile detection and simulation processing experimental device

An experimental device and line detection technology, applied in the mechanical field, can solve problems such as single function, fixed parameters, backward technology, etc., and achieve the effect of strong interaction, complete functions and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

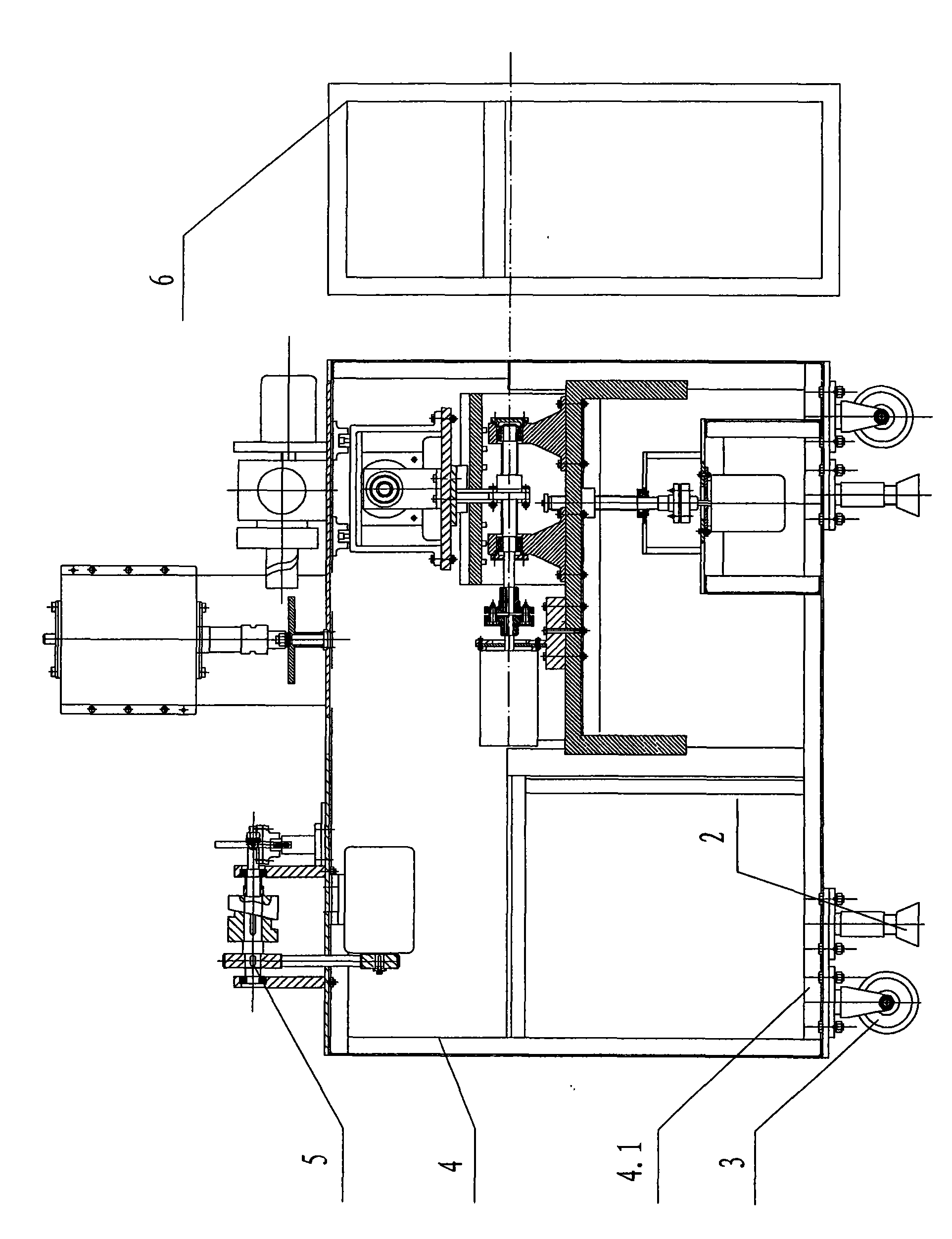

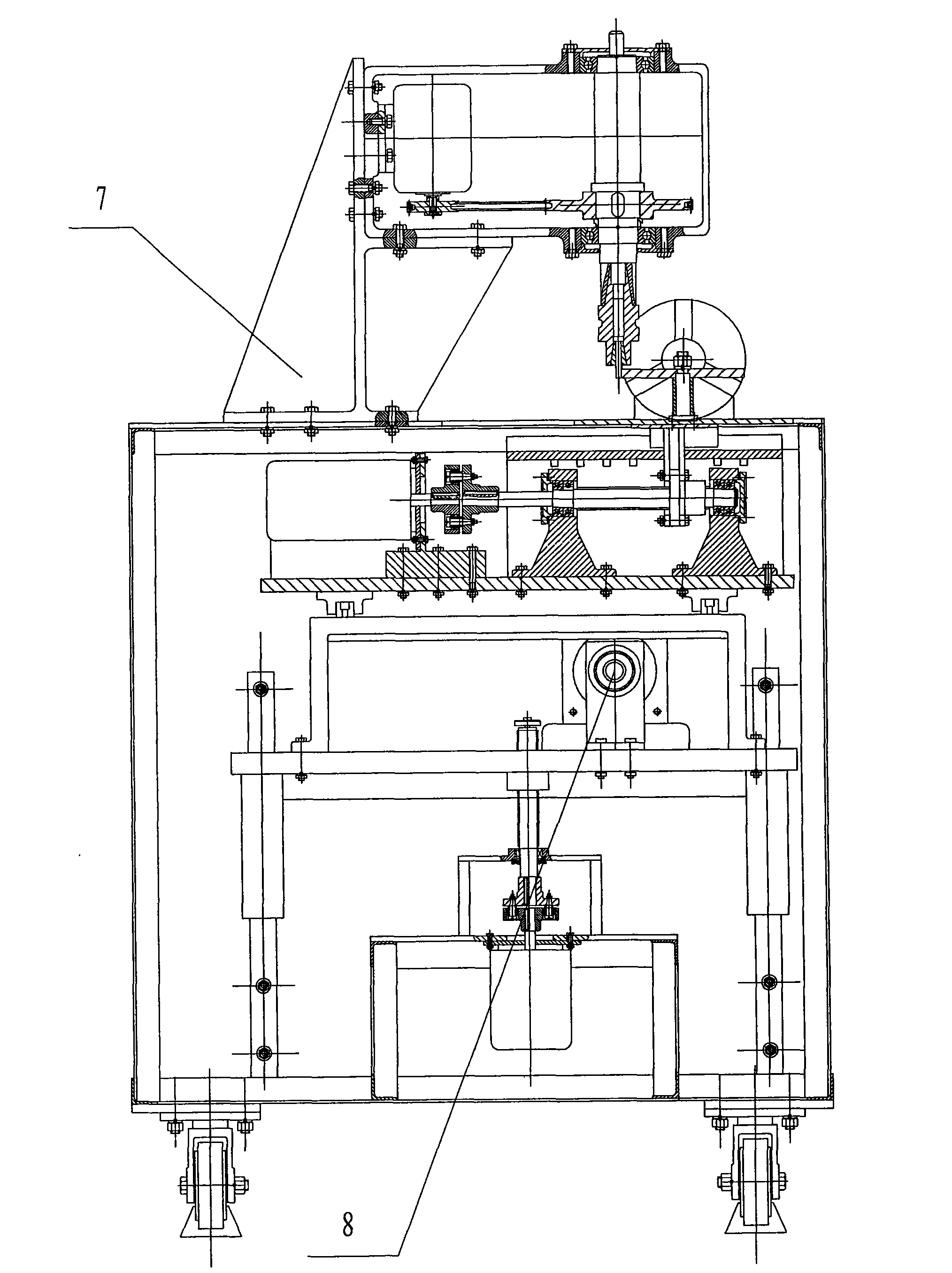

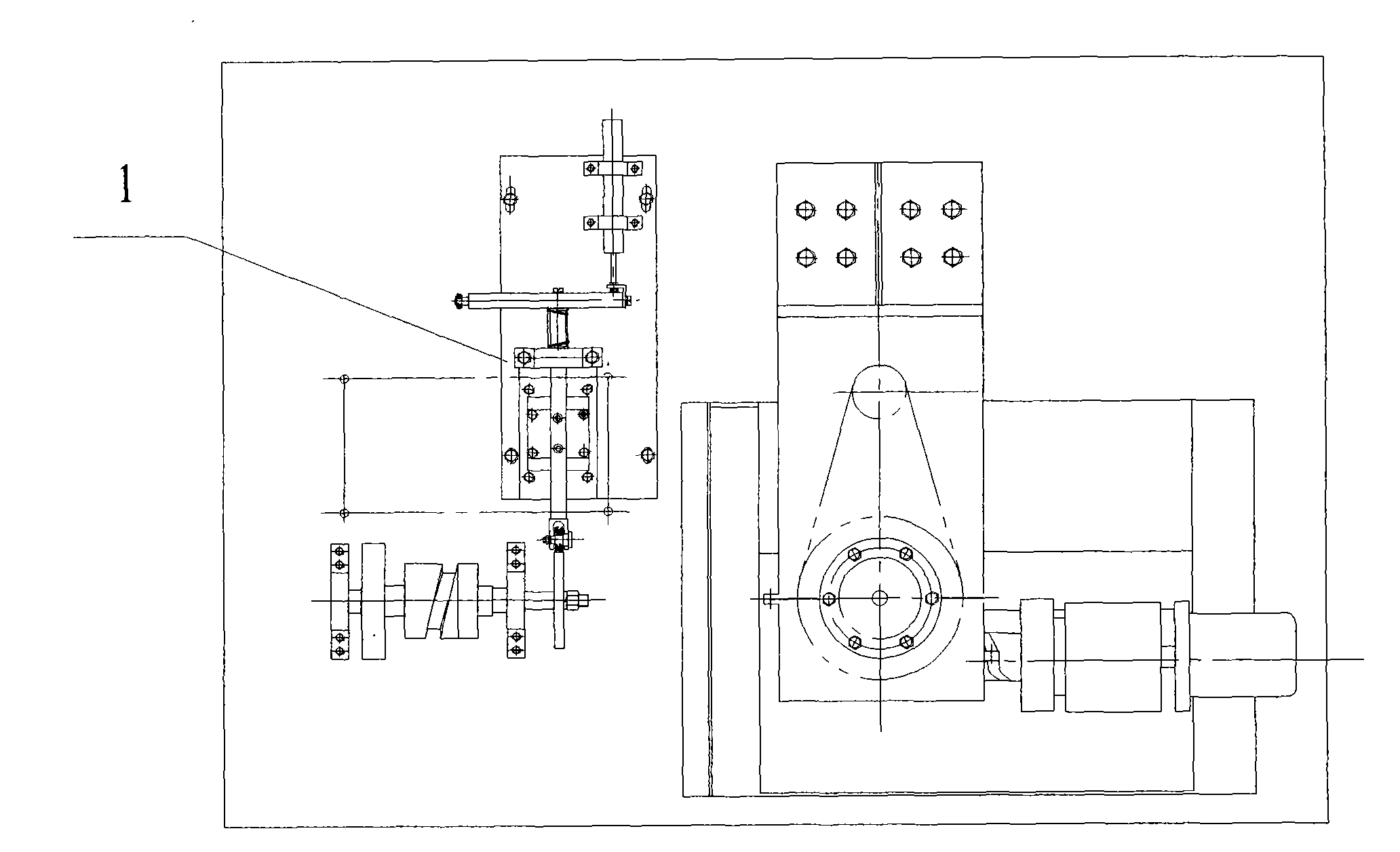

[0039] figure 1 , figure 2 , image 3 , Figure 4 It is the overall structure diagram of the present invention, and the present invention is made up of contour measuring mechanism 1, cabinet 4, tested cam installation mechanism 5, console 6, milling cutter part 7, workbench part 8. The cabinet 4 includes a welding table body 4.1, directional wheels 3, and support feet 2. The directional wheels 3 and support feet 2 are installed at the bottom of the welding table body 4.1. The directional wheels 3 are used for short-distance transposition of the test bench, and the support feet 2 are used for experiments. Fixing and leveling after positioning the table.

[0040] image 3 It is a schematic diagram of detecting the working profile of the disc cam, the roller at the end of the profile measuring rod of the disc cam is close to the contour surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com