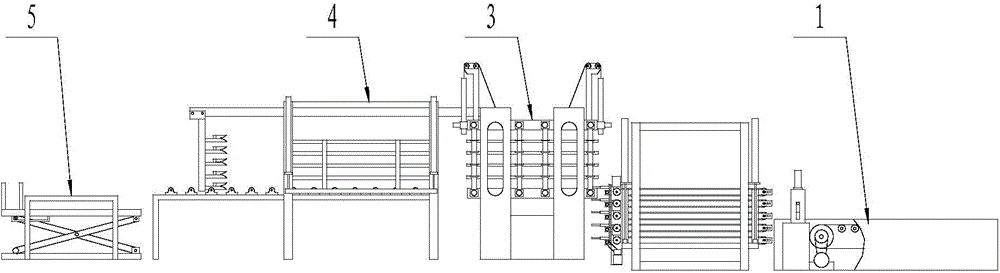

Woodworking plate paving-hot-pressing all-in-one machine

An all-in-one machine and woodworking board technology, which is applied in the direction of veneer presses, plywood presses, wood processing equipment, etc., to achieve the effects of high automation, stable rise, and high processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

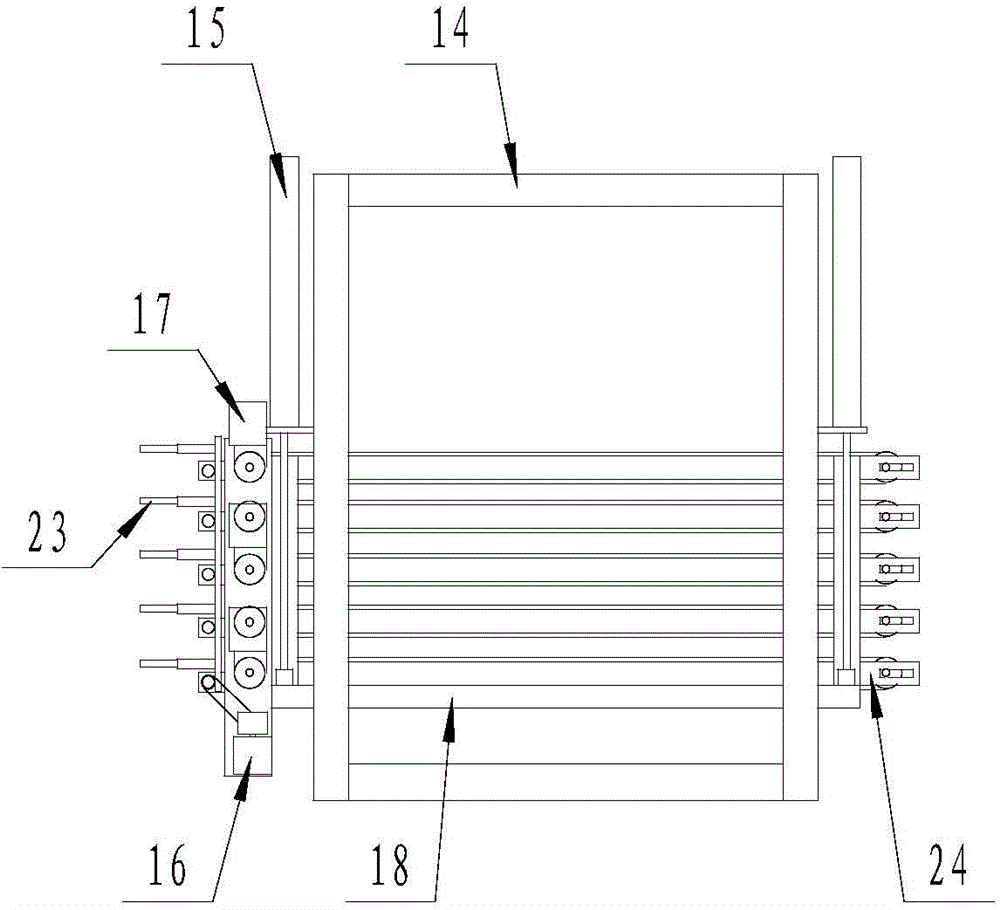

[0034] Figure 8, Figure 9 , Figure 10 As shown, the multi-layer hot press machine 3 comprises a multi-layer hot press frame 26, a pressing plate oil cylinder 38, an upper pressing plate 35, a carrier plate 29, a lower pressing plate 28, a positioning cylinder 27, a side positioning rod 30 and a suspension positioning rod 32, and the pressing plate oil cylinder 38 is connected with the lower pressing plate 28, the four sides of the upper pressing plate 35 and the lower pressing plate 28 are respectively provided with several sockets 34, and the four sides of the carrier plate 29 are respectively provided with some connecting rings 36, and the upper pressing plate 35, the lower pressing plate 28 and the carrier plate 29 pass through Socket 34 and connecting ring 36 are connected on the side positioning rod 30, and positioning cylinder 27 is fixed on the socket 34 outer walls, and its piston rod passes through socket 34 outer walls and links to each other with side positionin...

Embodiment 2

[0038] Such as Figure 11 As shown, the multi-layer hot press machine 3 also includes a synchronous closing device that can realize the simultaneous closing of each layer of the carrier plate 29, the upper pressing plate 35, and the lower pressing plate 28, so as to ensure that the time for each layer of spliced panels to be subjected to the plate hot-pressing treatment is the same; synchronous closing The device includes a synchronous link mechanism symmetrically distributed on both sides of the multi-layer hot press frame. The synchronous link mechanism includes an upper link 40, a lower link 39 and several intermediate links 41, wherein one end of the upper link 40 is connected to the upper platen 35 is hinged, it is provided with several jacks, one end of lower link 39 is hinged with lower platen 28, the other end of upper link 40 is hinged with the other end of lower link 39, one end of middle link 41 is hinged with carrier plate 29, and the other end is hinged with carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com