Mounting method of crane sliding contact line in workshop

An installation method and trolley line technology, which are applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of high error, difficult construction, and low construction efficiency, so as to improve safety, reduce construction costs, and improve construction. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

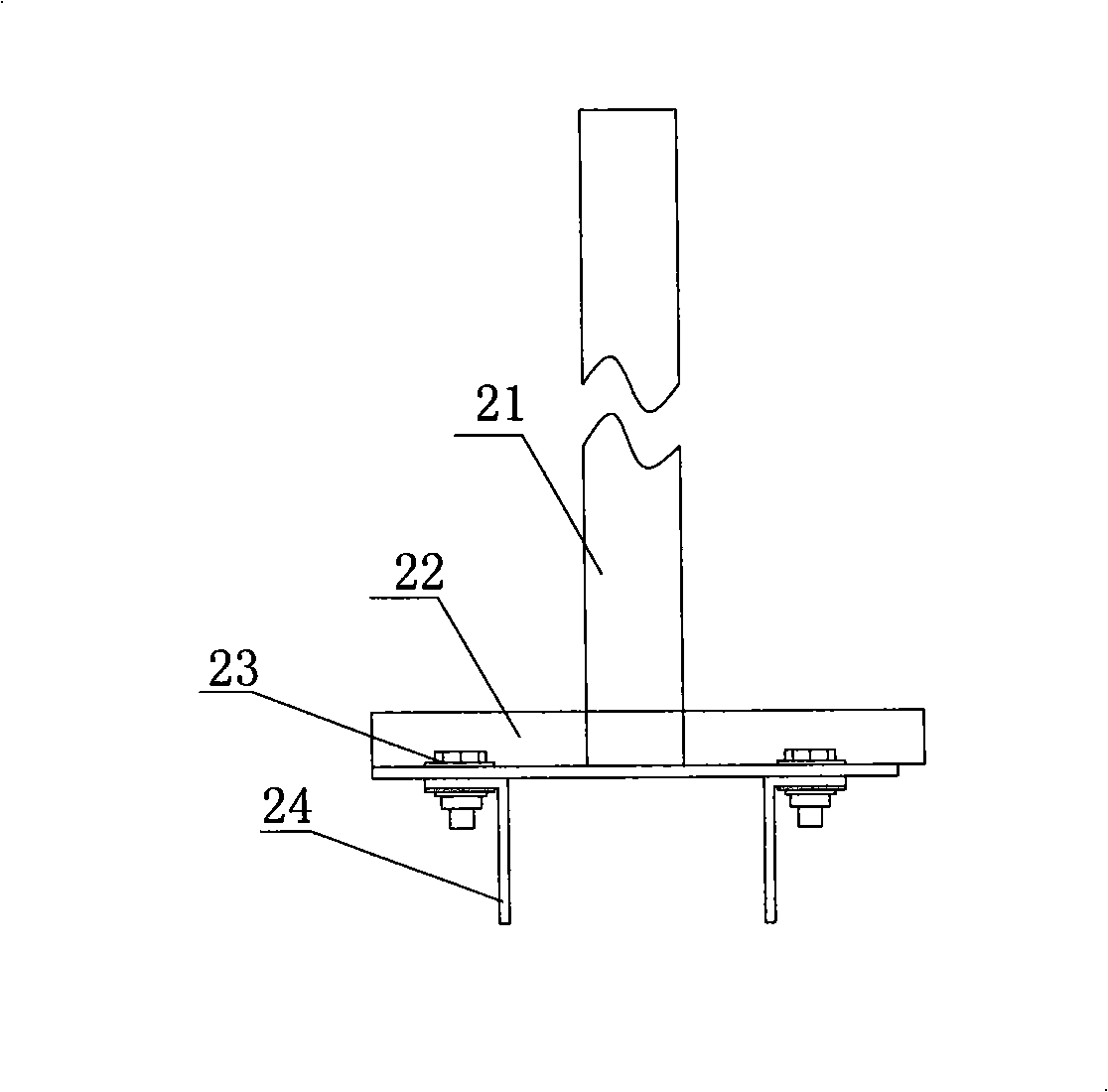

[0024] The invention is a new method for realizing the installation of the trolley line by using the trolley line bracket installation mold and the trolley line straightening detector. Make the trolley line bracket installation mold according to the trolley line installation height. Make a trolley line straightening detector according to the standard trolley line track spacing.

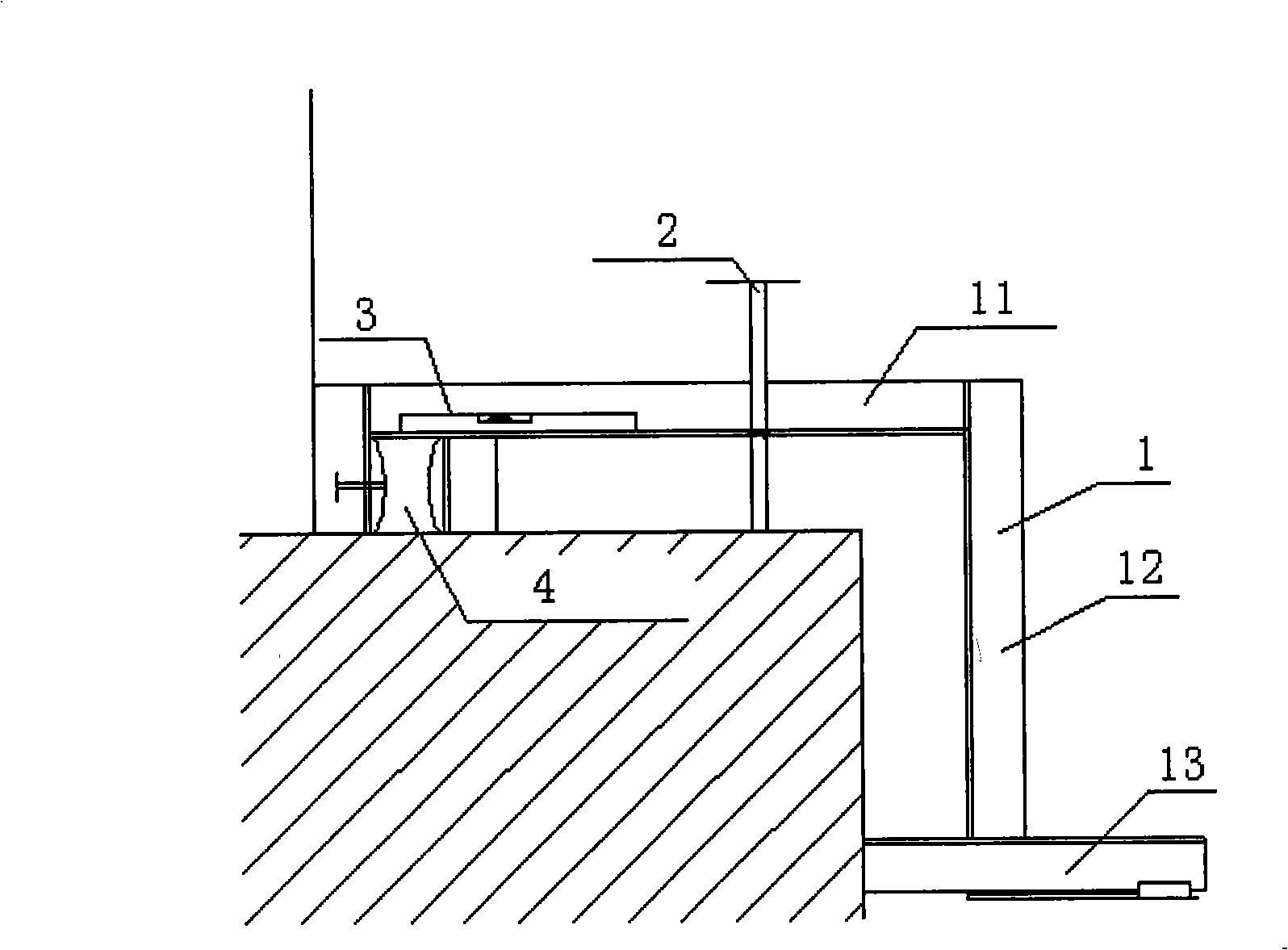

[0025] Such as figure 1 , a kind of mold for installing the sliding wire bracket, including a "Z" shaped frame 1, the "Z" shaped frame with the upper horizontal end 11 and the The lower horizontal end 13 and the vertical bar 12 vertically connected between the above-mentioned upper horizontal end and the lower horizontal end, a spirit level 3 and a level adjustment bar 2 are installed at intervals in its upper horizontal end 11, and the vertical bar 12 is vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com