Garlic root cutter

A technology of root cutting and garlic, applied in the fields of application, food processing, food science, etc., can solve the problems of garlic root cutting, difficulty in management, promotion and use, etc., to reduce labor intensive, high efficiency of root cutting, cleverly structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

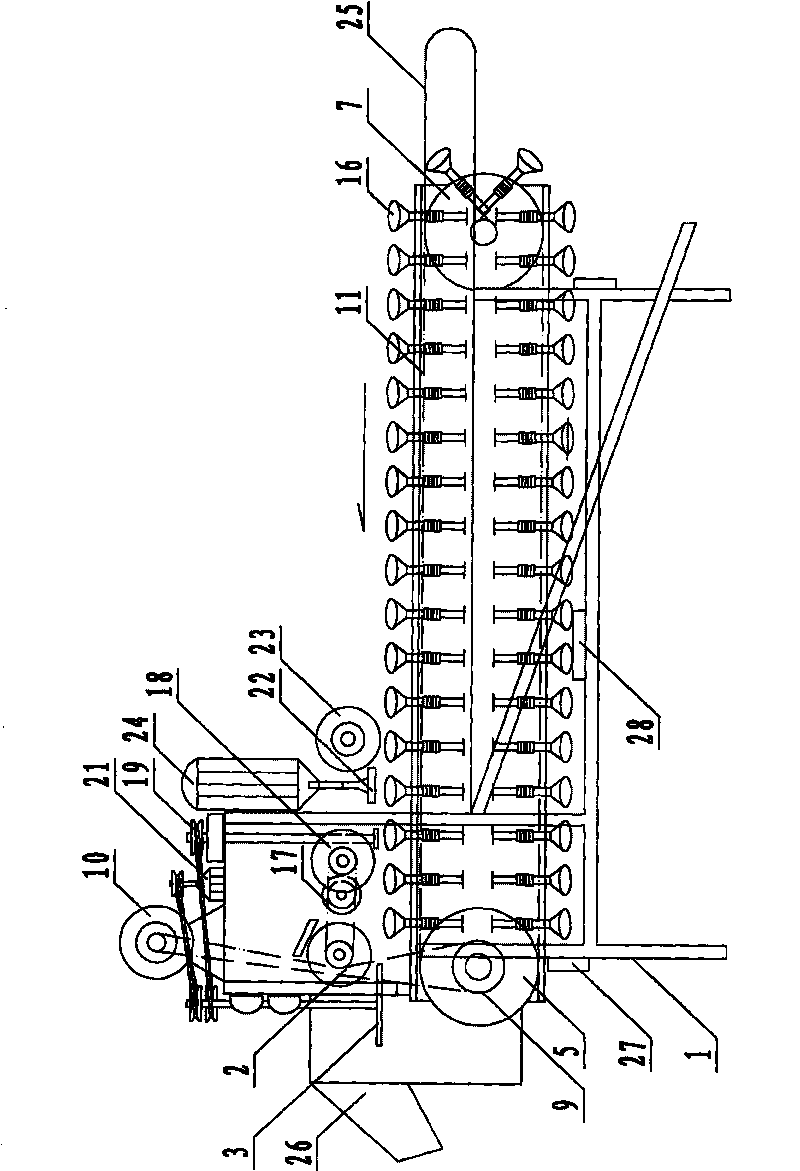

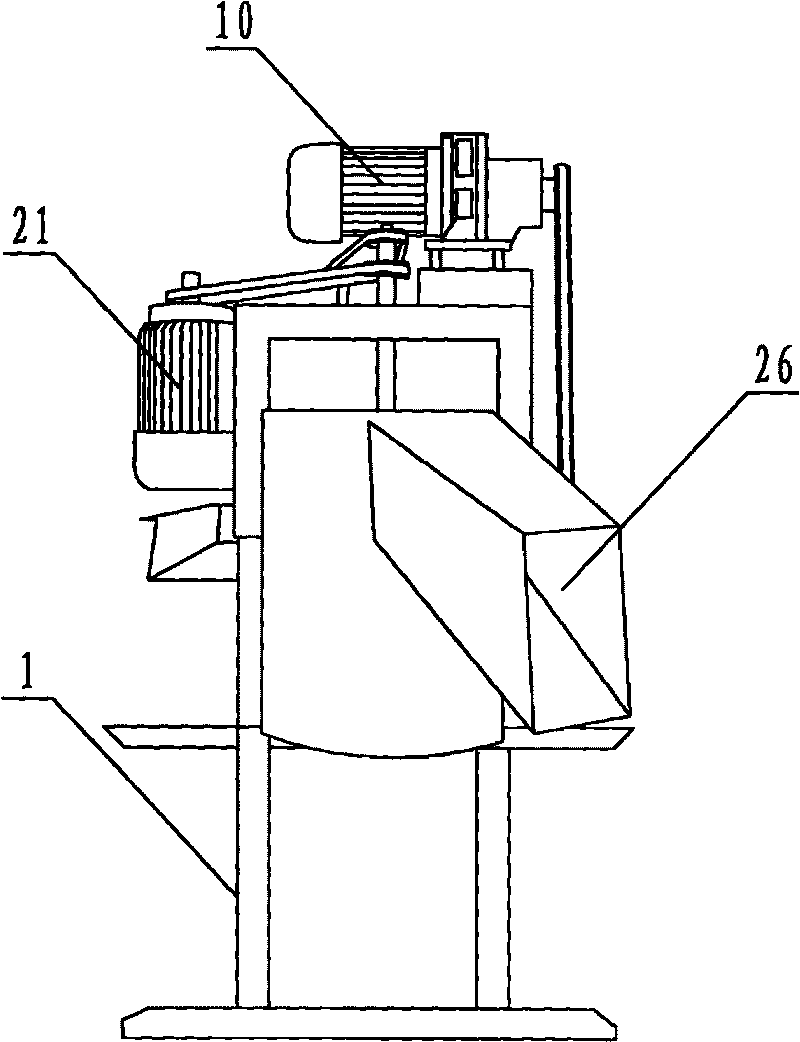

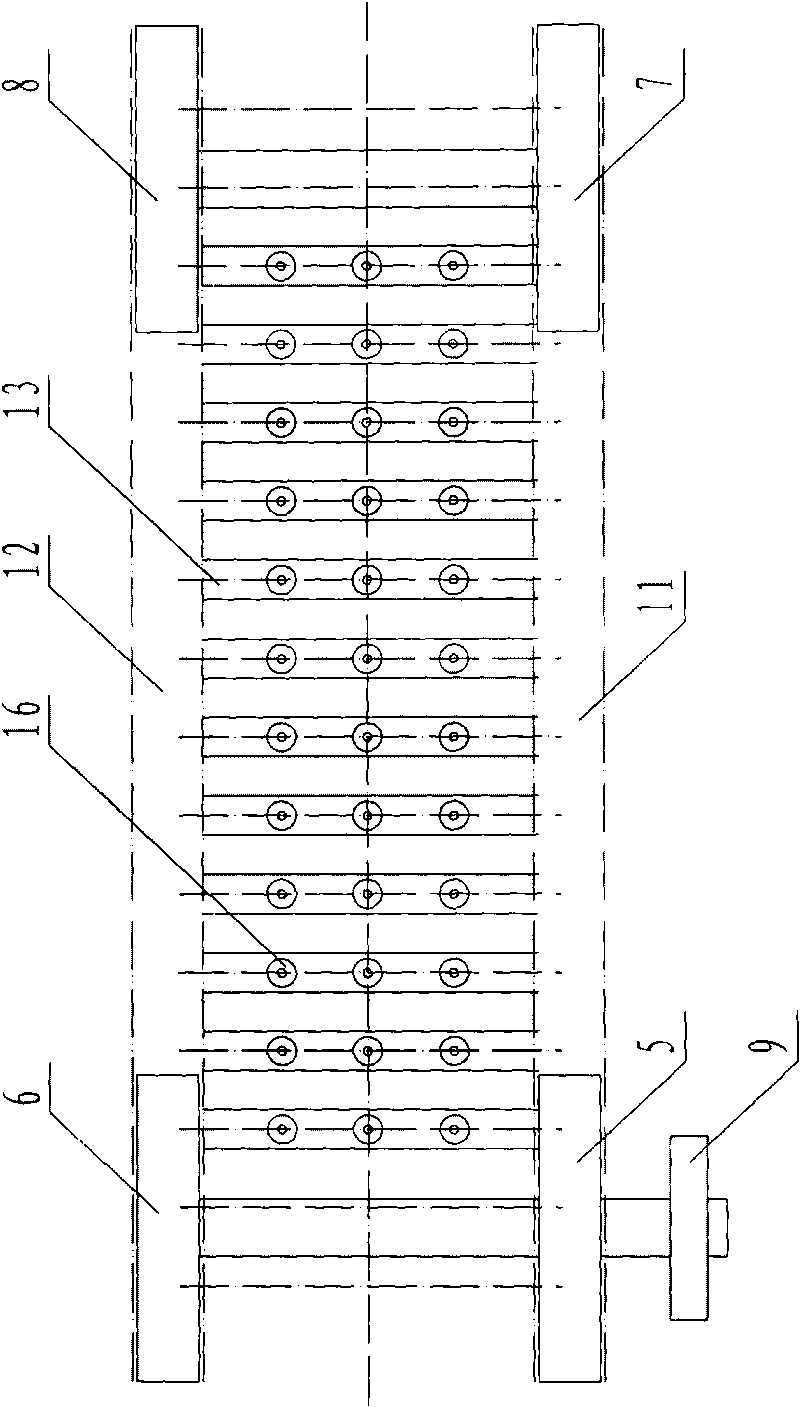

[0031] Attached below Figure 1-12 The garlic root cutter of the present invention is described in detail below.

[0032] as attached figure 1 , 2 , shown in 7, the garlic root cutting machine of the present invention, its structure comprises frame 1 and the sprocket chain transmission mechanism that is installed on the frame 1, is provided with material cup assembly on the sprocket chain transmission mechanism, sprocket chain transmission mechanism It is connected with the power mechanism and drives the material cup assembly to rotate from back to front around the chain wheel. At the front end of the frame 1, there is a root cutting roller 2 connected with the cycloidal needle motor 10 and connected with the power motor 21. The serrated blade 3 is provided with a wheel cleaner 4 on one side of the root cutting roller 2, and the wheel cleaner 4 promptly cleans up the sundries stuck on the root cutting roller 2, and the rotation plane of the serrated blade 3 is parallel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com