Rotation machine axial force testing apparatus and testing method thereof

A technology for rotating machinery and testing devices, applied in the field of rotating machinery, can solve the problems of measurement difficulty, inconvenience, and inability to accurately measure axial force, etc., and achieve the effects of easy popularization and application, wide versatility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

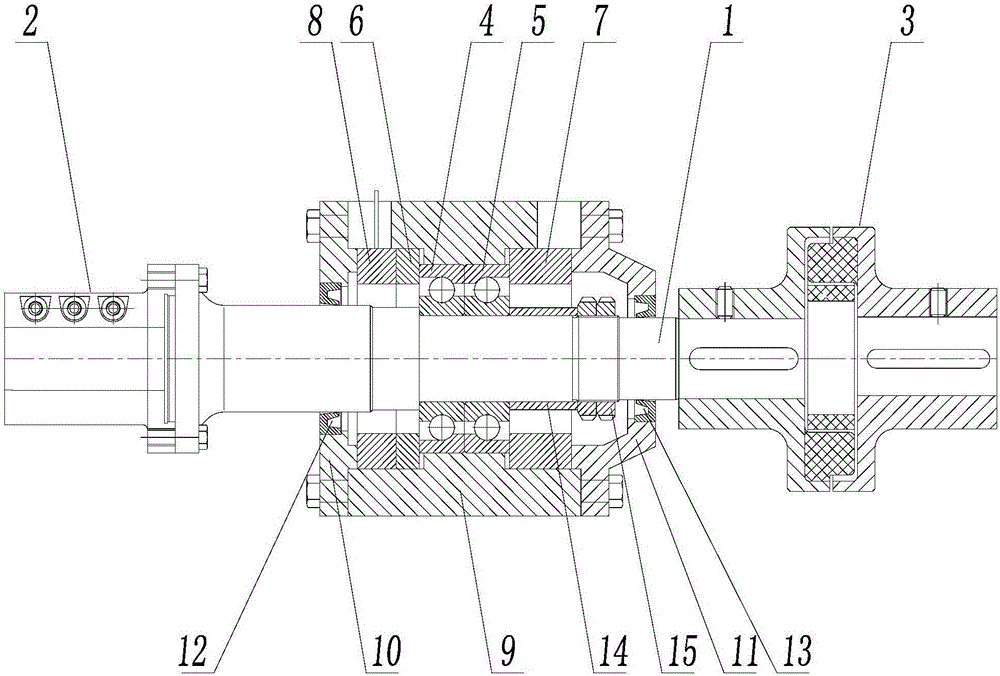

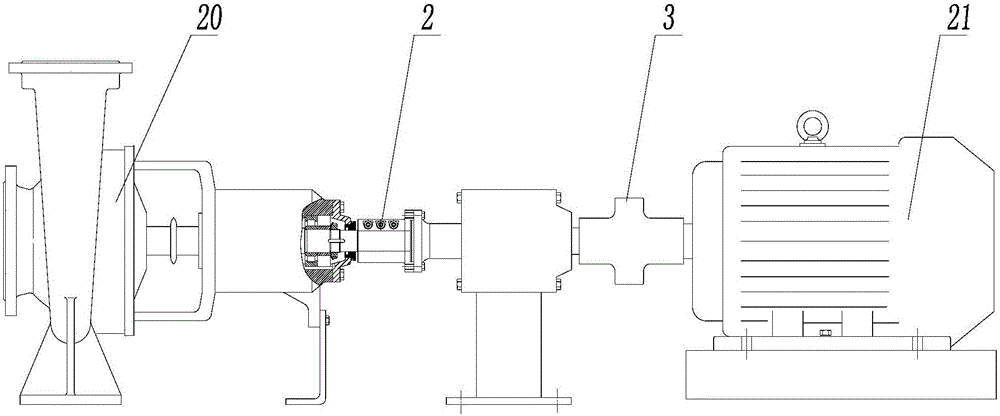

[0034] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, which is used to measure the axial force in the direction of the first bearing. Such as figure 1 As shown, an axial force testing device for a rotating machine includes a housing, a bearing, a rotating shaft 1 and a sensor, the rotating shaft 1 is fixedly connected to the inner ring of the bearing, the outer ring of the bearing is fixedly connected to the housing, and is fitted on the rotating shaft 1 The sensor, the output signal of the sensor is electrically connected to the signal processing device, the rotating shaft 1 and the rotating machine adopt a keyless connection, and the rotating shaft and the motor are connected by a coupling.

[0035] The rotating shaft 1 is a stepped rotating shaft, one side of the inner ring of the bearing leans against the step of the rotating shaft 1, and the other side is fixed by the shaft sleeve 14 and the lock nut 15, so as to realize axial fas...

Embodiment 2

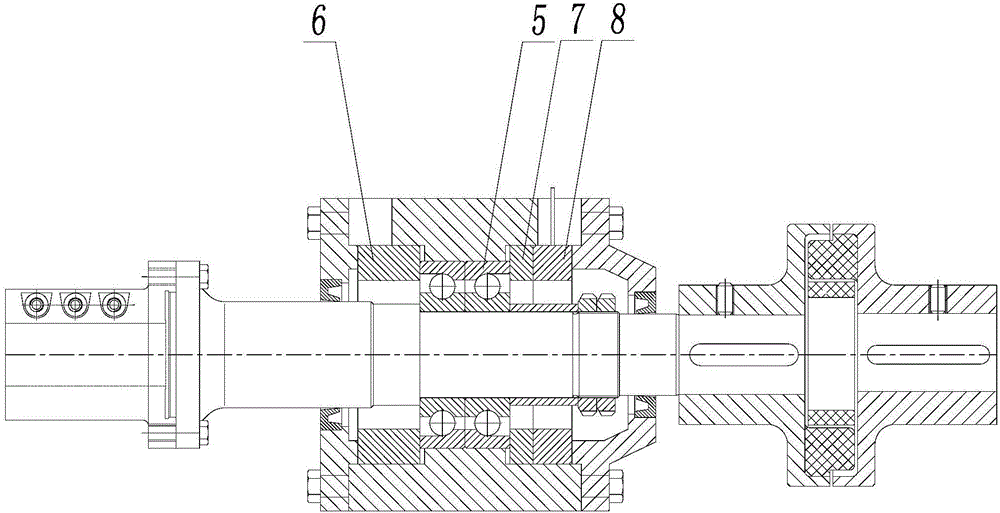

[0041] image 3 It is a structural schematic diagram of Embodiment 2 of the present invention, which is used to measure the axial force in the direction of the second bearing. Such as image 3 As shown, the sensor 8 of the second embodiment is arranged outside the outer ring of the second bearing 5 , and the second compensation ring 7 is arranged between the second bearing 5 and the sensor 8 . Other configurations of the second embodiment are the same as those of the first embodiment, and will not be repeated here.

Embodiment 3

[0043] Figure 4 It is a structural schematic diagram of Embodiment 3 of the present invention, which is used to measure the axial force in the first bearing direction and the second bearing direction. Such as Figure 4 As shown, the bearing of the third embodiment includes the first bearing 4 and the second bearing 5 that are close together. The bearing of the third embodiment is an angular contact ball bearing, which is characterized in that it can bear a large axial force and has directional , equipped with two bearings can adapt to the axial force requirements in two directions; the sensor is two sensors, including the first sensor 8 and the second sensor 16, the first sensor 8 is set outside the outer ring of the first bearing 4, and the second The outer side of the outer ring of the second bearing 5 is provided with a second sensor 16, a first compensation ring 6 is provided between the first bearing 4 and the first sensor 8, and a second compensation ring 7 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com