Large-scale shaft products vertical casting and repairing device and using method

A vertical casting and shaft technology, which is applied in processing machinery, casting and repairing processing machinery of shaft products, and mechanical fields, can solve problems such as promotion restrictions and high cost pressures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0071] On the basis of implementation according to specific embodiment 1, the thermal insulation tank 3, thermocouple 18, sensor 19, motor 12 for controlling the workpiece 13, and control for lifting The motors of the 11 lifting speeds are all electrically connected to the data information collection and processing monitor and implemented; the expected good effect has been obtained.

specific Embodiment approach 3

[0072]On the basis of carrying out according to specific embodiment 1, the thermal insulation tank 3, the guide pipe 4, the leak-proof tank 5, the sealing ring 16, and the sprue cup 17 described in the vertical casting and repairing device of the large-scale shaft products , thermocouple 18, inductor 19, and leak-proof groove 22 are all provided with a temperature-resistant layer and implemented; the expected good effect has been obtained.

specific Embodiment approach 4

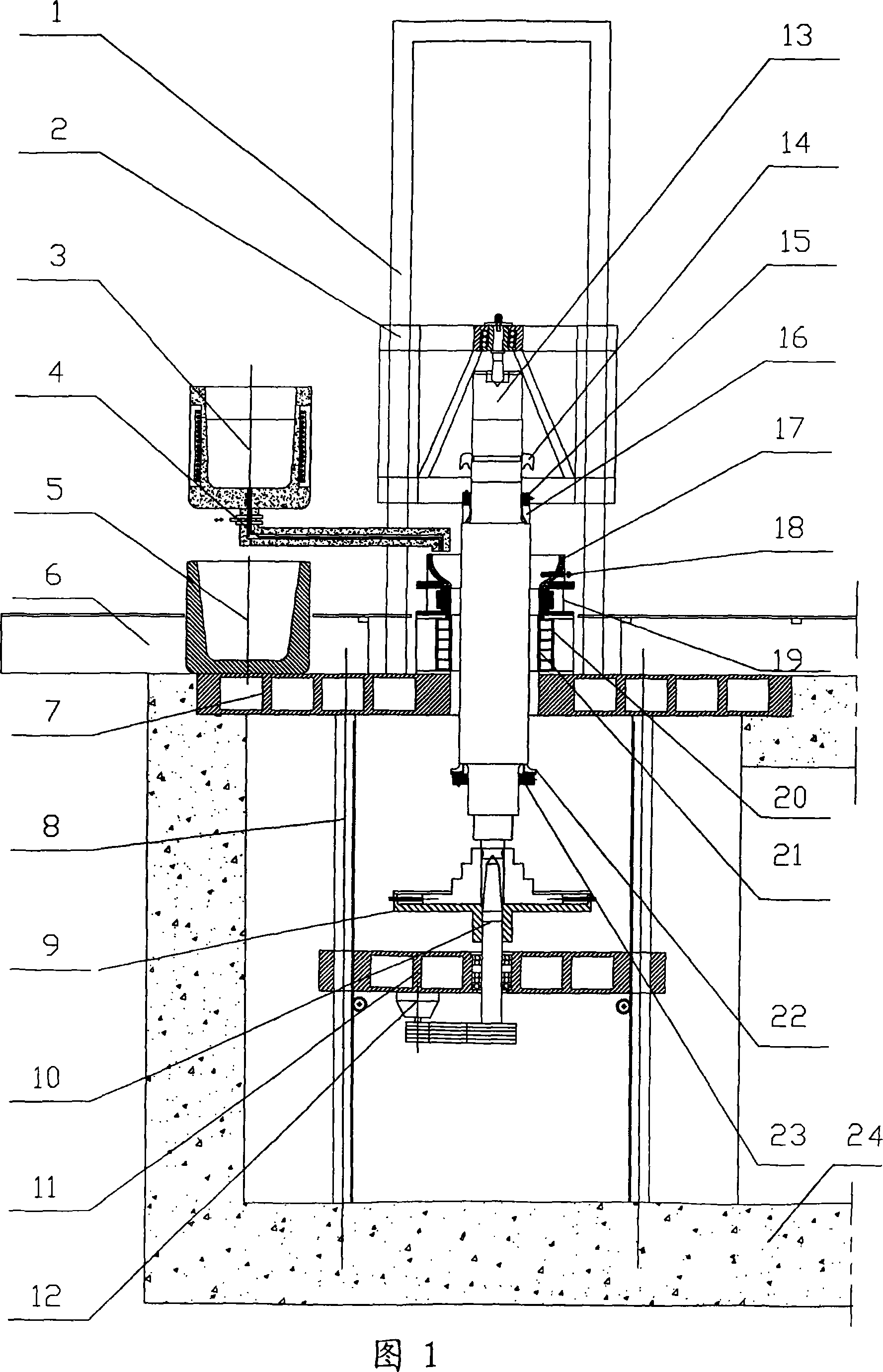

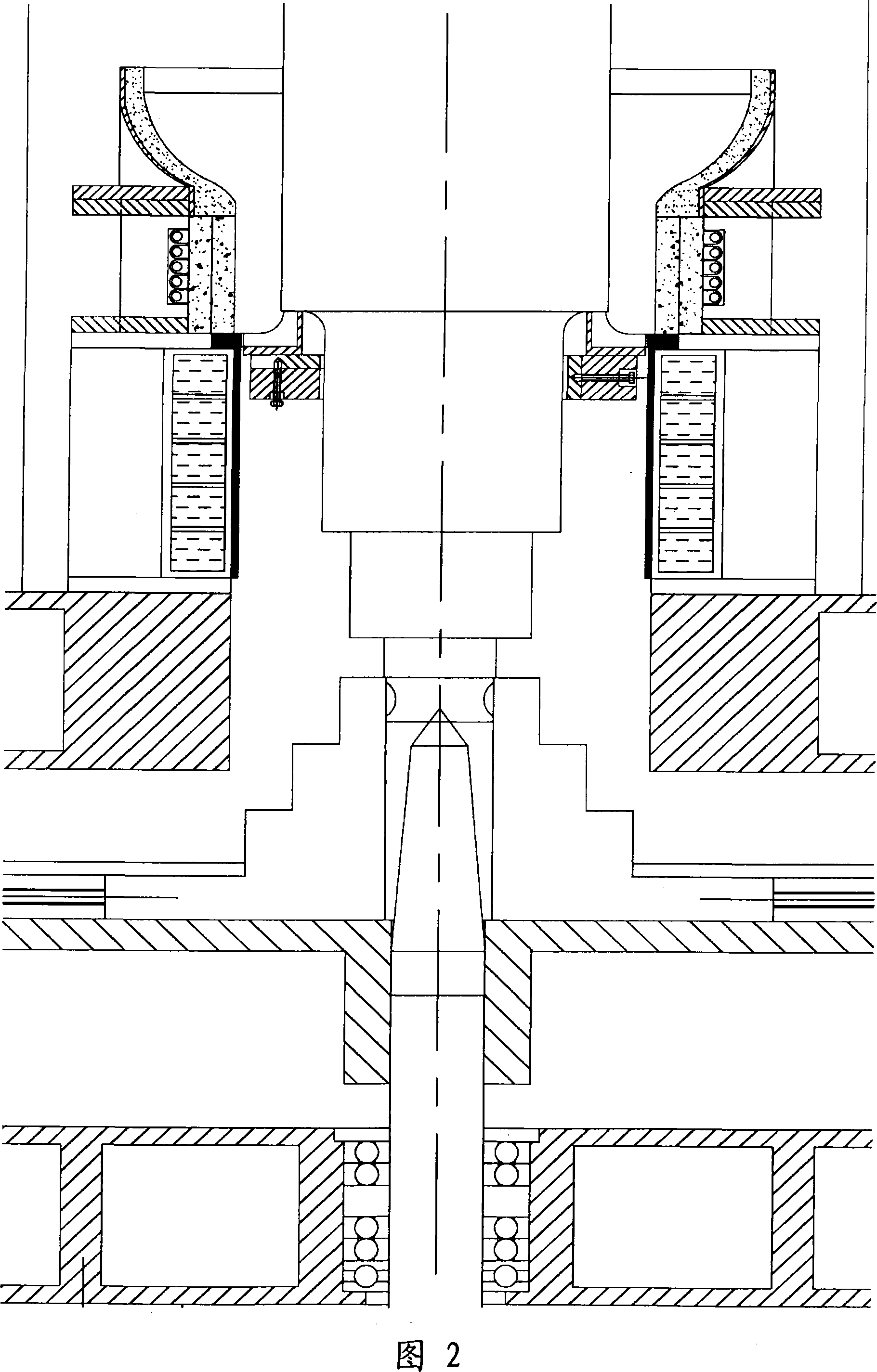

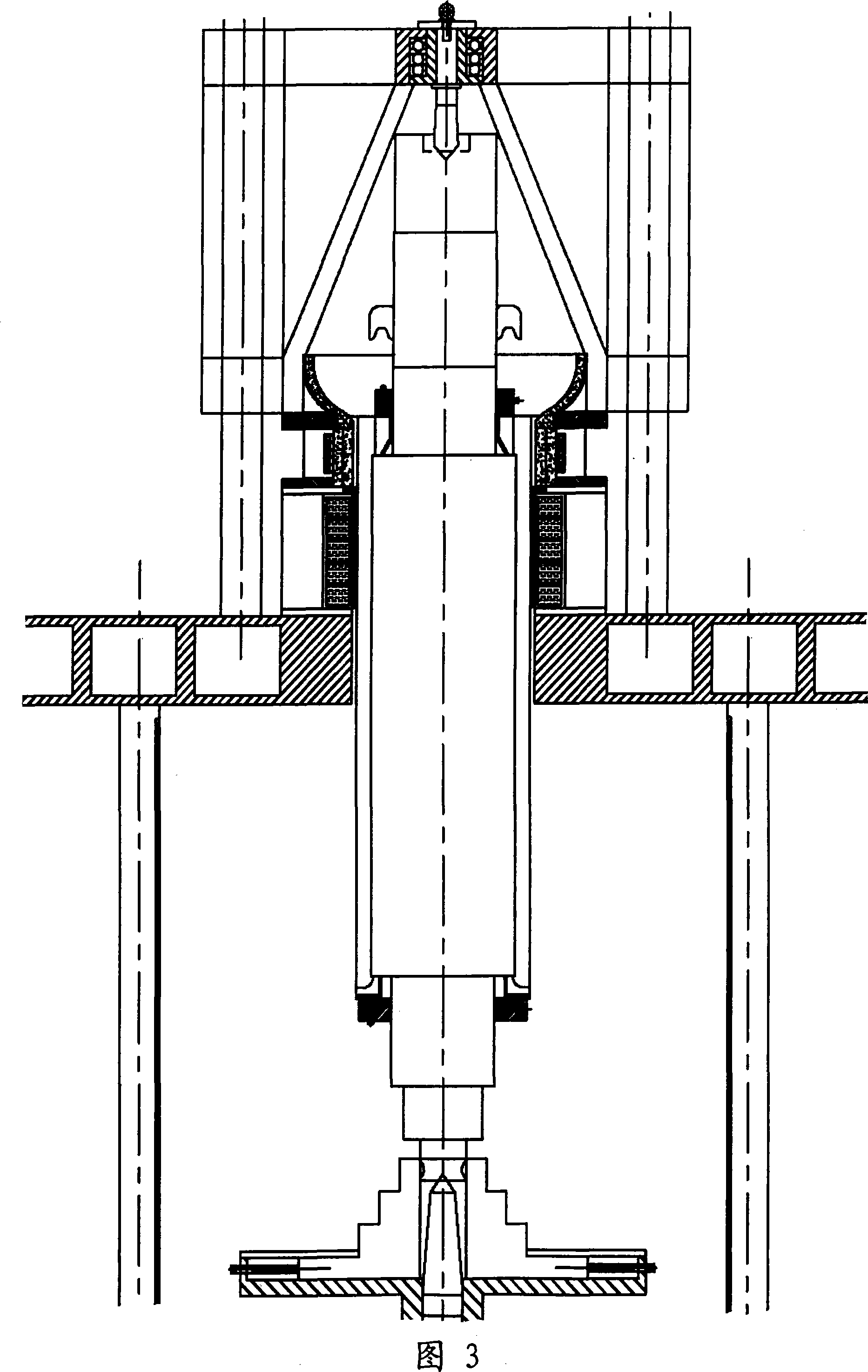

[0073] The method of using the vertical casting and repairing device for large-scale shaft products in the present invention will be described in detail below in conjunction with the accompanying drawings. As shown in Figures 1, 2, 3, 4, 5, 6, 7, and 8 of the description:

[0074] A method for using a vertical casting and repairing device for large-scale shaft products, using the vertical casting and repairing device for large-scale shaft products described in Embodiment 1, and following the steps below:

[0075] (1) Workpiece treatment: chrome-plate the workpiece with a diameter of 1200mm and a length of 3500mm after degreasing, and heat the workpiece after chrome plating to 450°C;

[0076] (2), the installation of the workpiece:

[0077] (2). ①. Install the sealing ring and upper locking ring on the workpiece, lift the workpiece through the fixture on the upper locking ring and insert it into the pouring described in the vertical casting and repairing device for large shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com