Board edge cutting machine

A technology for edge trimmers and boards, applied in wood processing appliances, sawing equipment, circular saws, etc., can solve problems such as shortages, and achieve the effects of saving production costs, improving accuracy, and improving working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

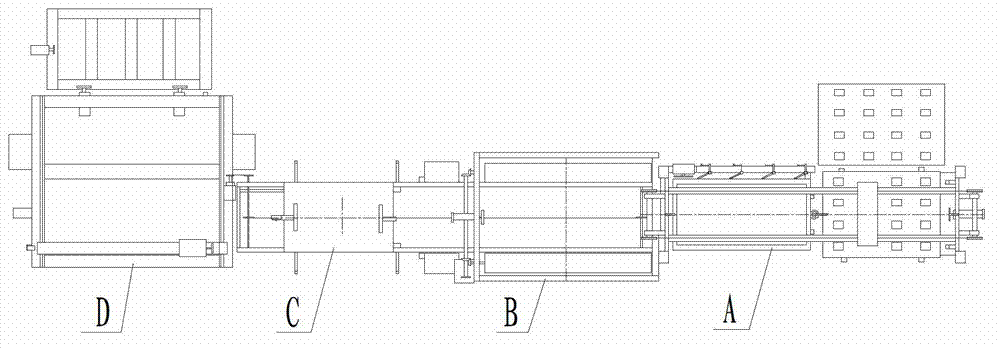

[0039] like figure 1 As shown, a board trimming machine includes a board feeding machine A, a board dropping machine B, a longitudinal trimming machine C, a horizontal trimming machine D and a control system, and the board feeding machine A includes a board feeding frame A2, a positioning Platform A3 and elevator IA1, the tail of the board feeder A is connected to the head of the board dropper B, a part of the longitudinal edge trimmer C extends into the inside of the board dropper B, and the longitudinal edge trimmer C is connected to the horizontal trimmer The side machines D are vertically connected, and the control system includes an electrical cabinet and control lines.

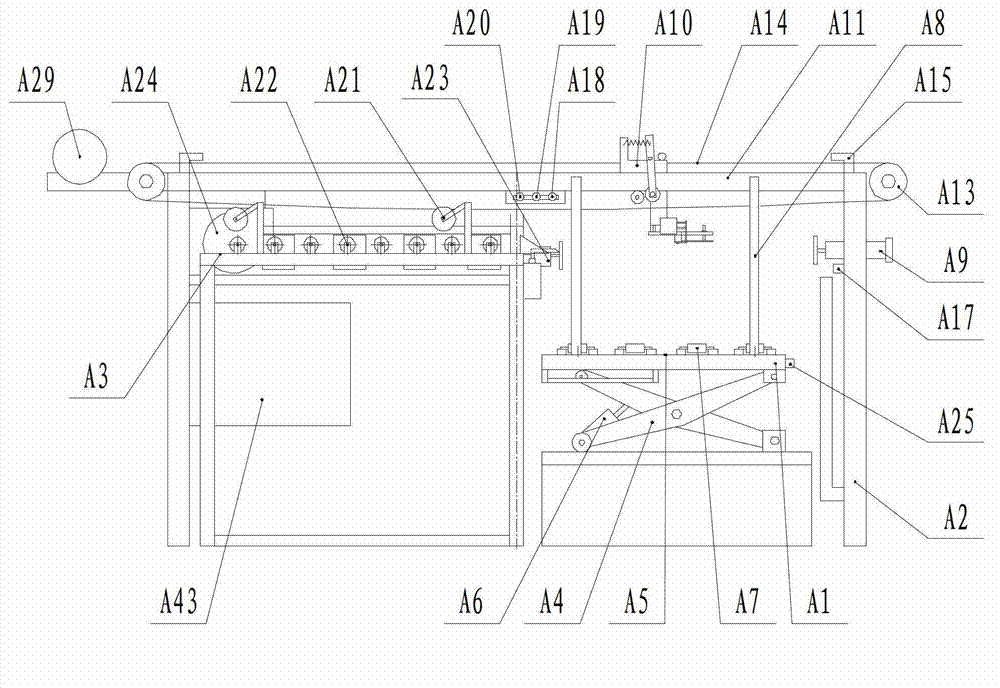

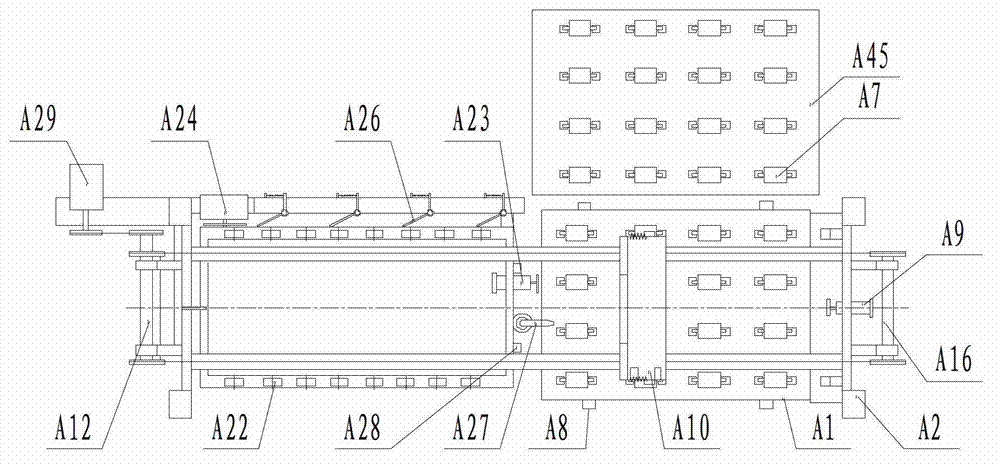

[0040] like figure 2 , image 3 As shown, the board feeding guide rail A11, the push head A10 and the push head transmission device are fixed above the board feeding frame A2, wherein the push hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com