System and method for monitoring rotary drilling machine

A technology of rotary drilling rig and monitoring system, which is applied to the automatic control system of drilling, drilling equipment, earth-moving drilling, etc. Credit management services, fast remote mechanical fee inquiry and loan credit management functions, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

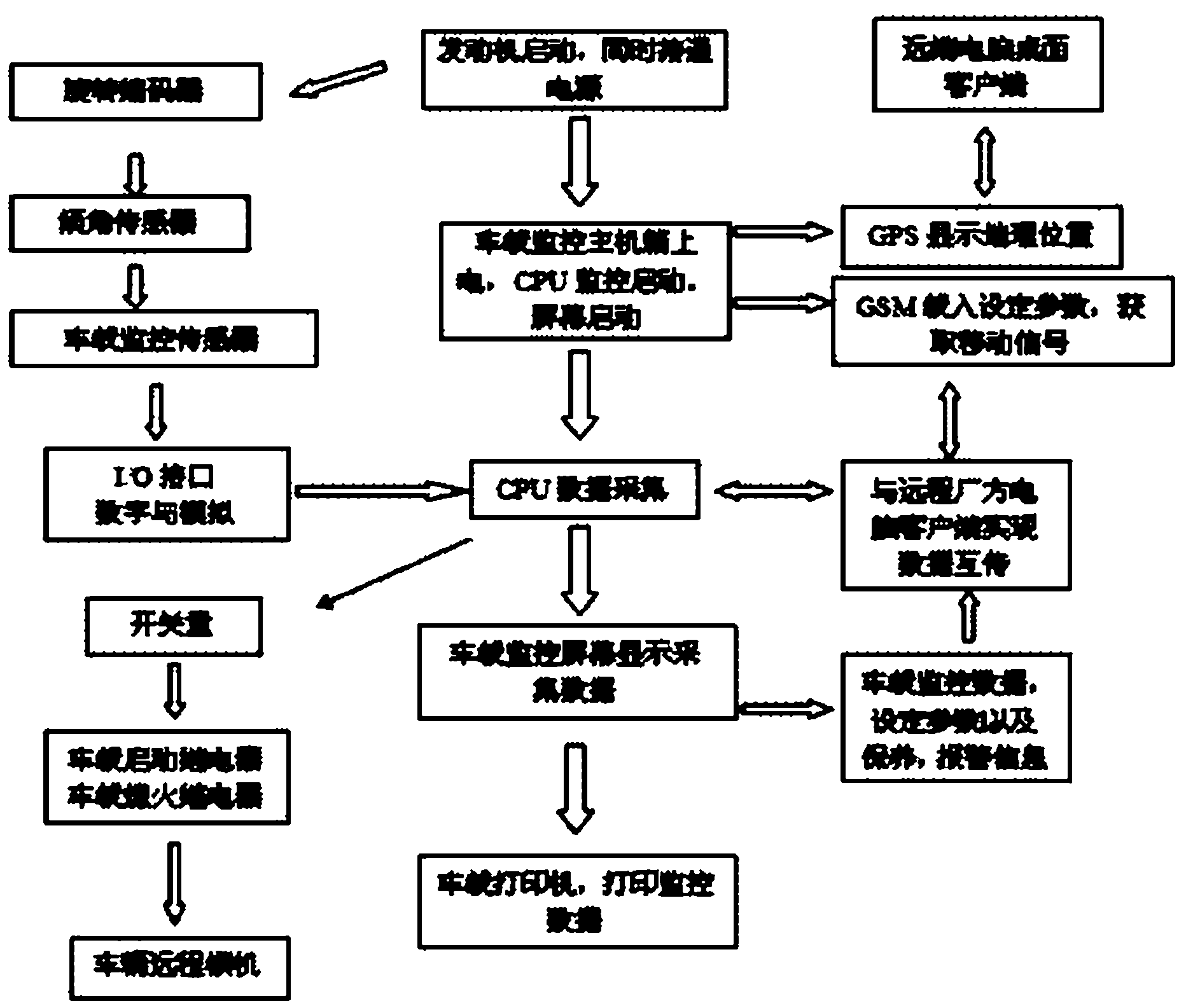

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] The system includes software and hardware parts, and is divided into local and remote modules according to distance.

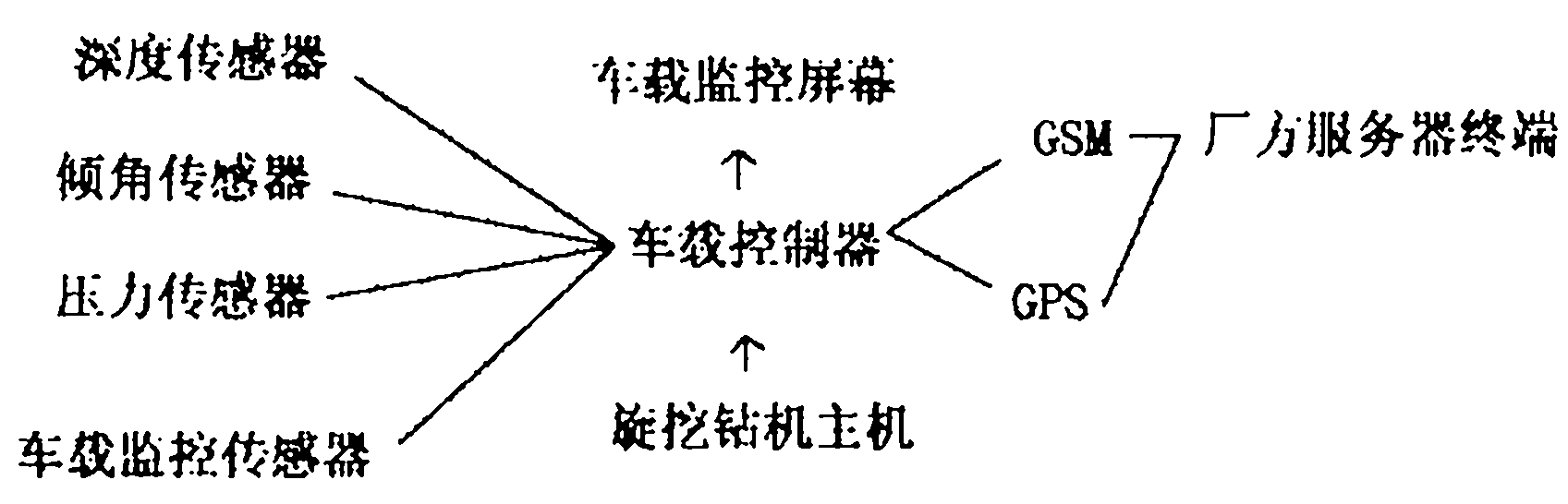

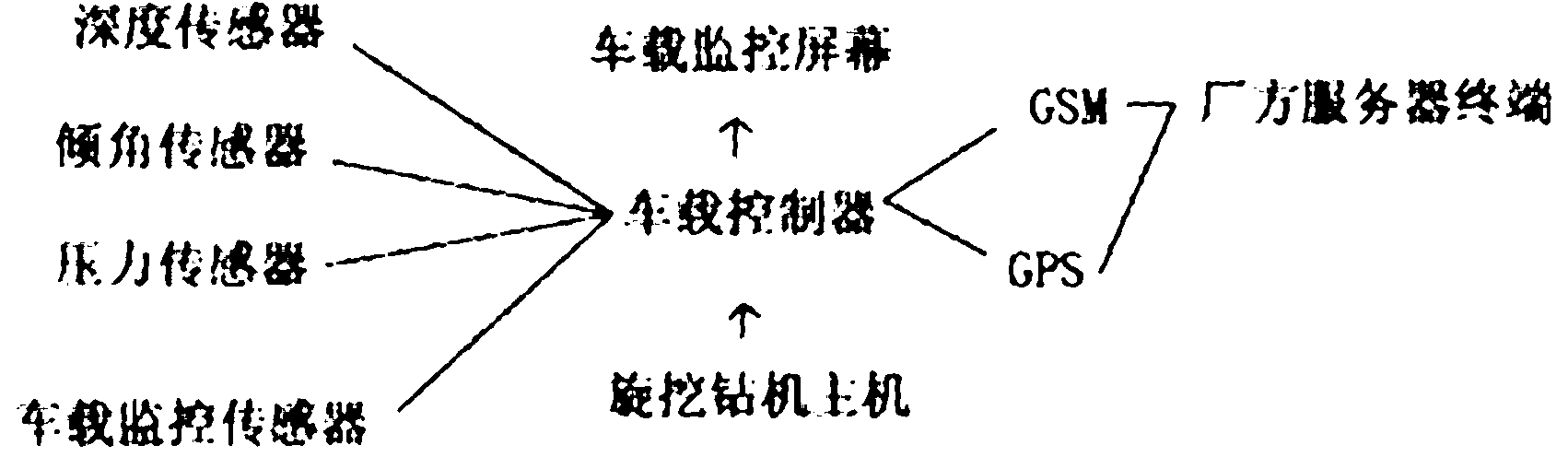

[0028] see figure 1 , the hardware includes:

[0029] Near-end monitoring equipment: including a touch screen used to display the vehicle data has been maintained and print data to the operator of the machine, the core component of the control box product, mainly responsible for computing and communication functions, GSM communication module, GPS positioning module;

[0030] Remote server management center: Including the client system and GSM communication module independently developed for this system in the server, it is used for remote communication with the machine supervisor.

[0031] Among them, the core device of the monitoring system is the on-board controller, which is responsible for collecting sensing information and location inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com