Plastic differential film rolling device for clothes

A film winder and plastic technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problems of slow speed, affecting the appearance, and inconvenient to fix the plastic film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

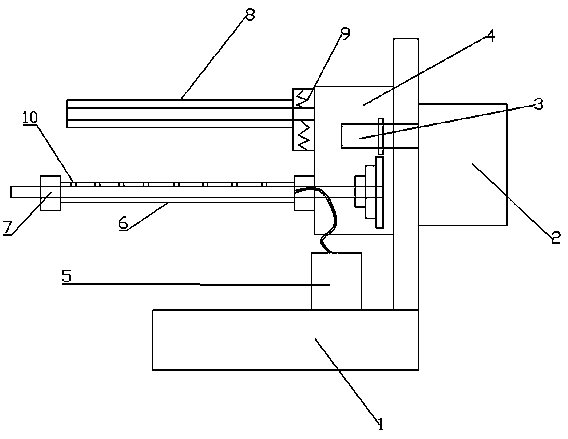

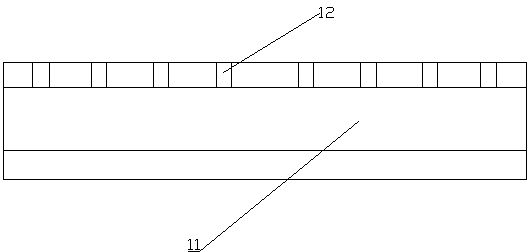

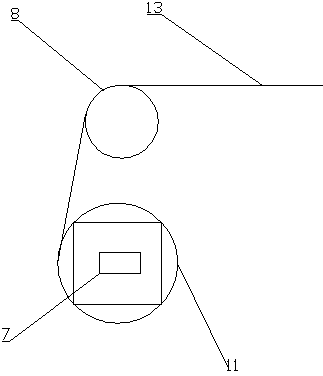

[0010] Figure 1 to Figure 3 In the schematic diagram of the plastic differential film winder for clothing shown, the plastic differential film winder for clothing includes a frame 1, a motor 2, a gearbox 4 and a film winding rod 6, and the motor 2 is connected to the gearbox through the main shaft 3 4, the power input end, the power output end of the gearbox 4 is connected to the film roll rod 6, the film roll rod 6 is a hollow tube, the port of the film roll rod 6 away from the gearbox 4 is closed, and the port close to the gearbox 4 is connected by a pipeline To the exhaust fan 5, some through holes A10 are set on the film rolling rod 6, and the through holes A10 communicate with the inside of the hollow pipe and the outside of the hollow pipe; A number of through holes B12 are arranged on the top, and the sleeve 11 is fixed on the hollow tube through the locking ring 7, and the through holes A10 correspond to the through holes B12 one by one. A tension control device is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com