Core bar for high-pitch precision spiral line and manufacturing method of core bar

A technology of helical wire and core rod, which is applied in coil manufacturing, discharge tube/lamp manufacturing, cold cathode manufacturing, etc., can solve problems such as inability to meet process requirements, avoid difficulty in controlling radial dimensions, ensure straightness and appearance The effect of diameter accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

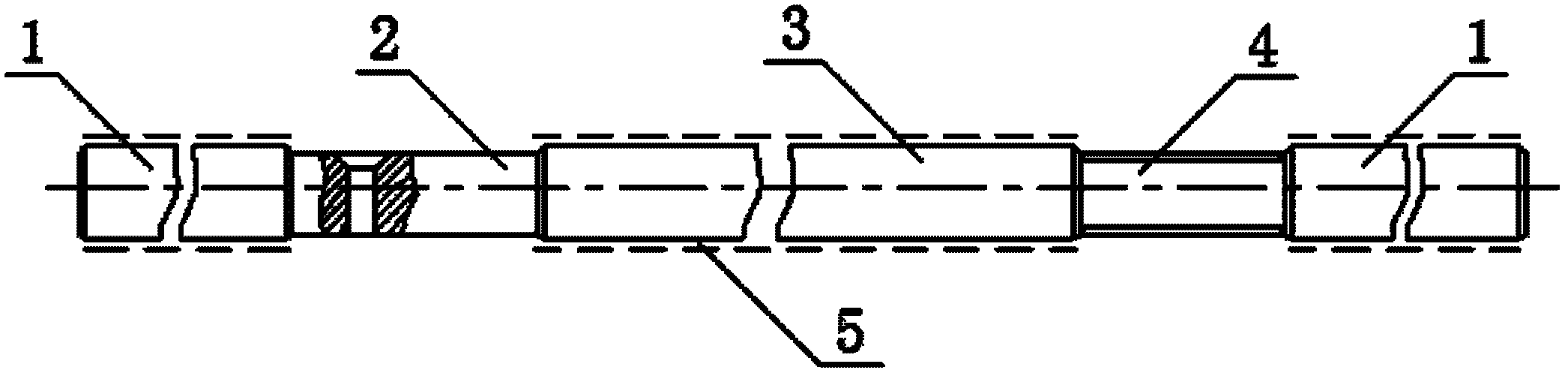

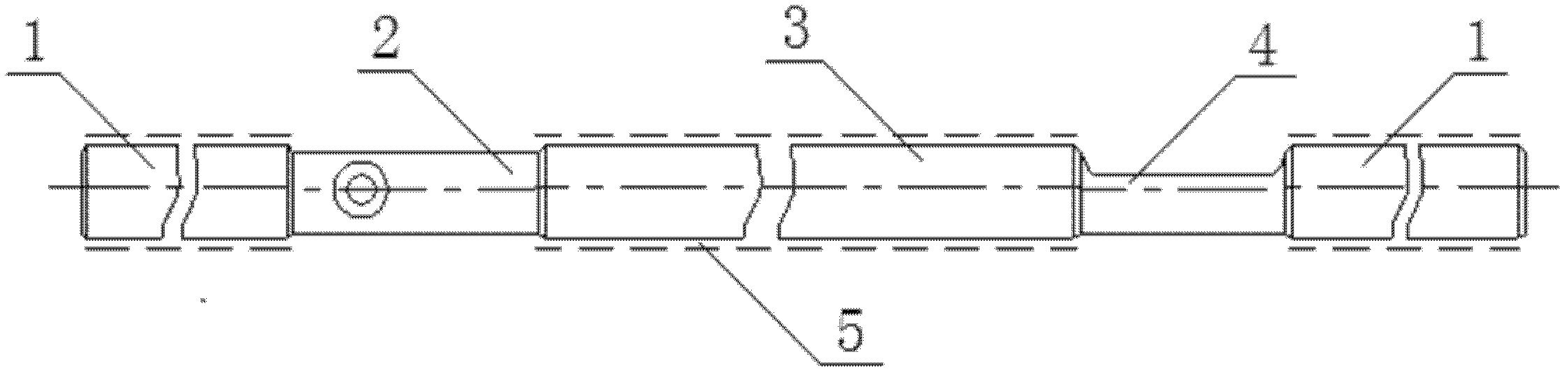

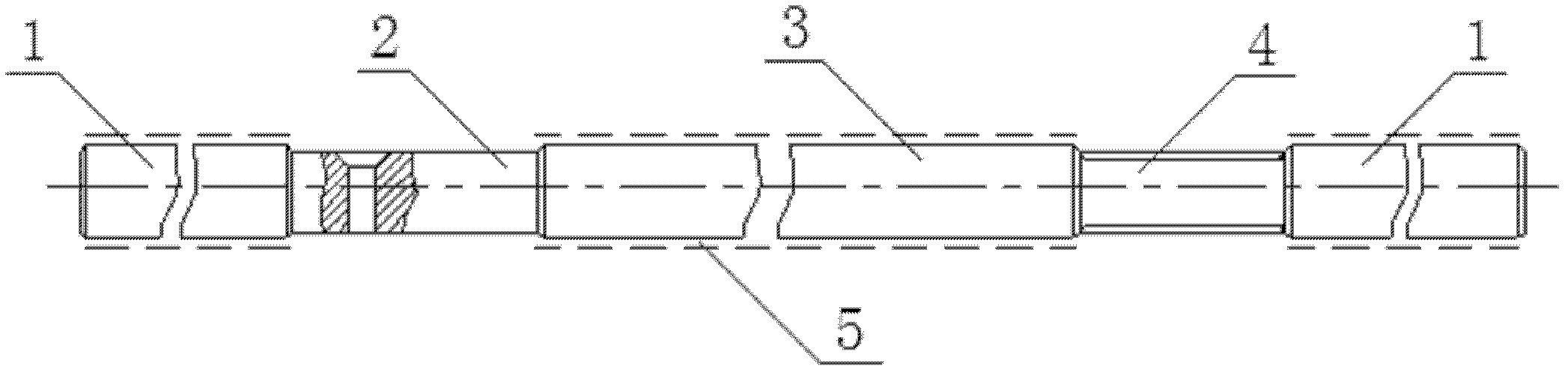

[0029] Depend on Figure 1-2 It can be seen from the combination of the shown structures that the core rod used for the high-pitch precision helix is a slender linear structure, which sequentially includes a process section 1, a hole-like structure 2, a spiral winding section 3, a plane structure 4 and a process section. 1. The spiral winding section 3 is located in the middle position, one end of which is the hole-like structure 2, and the other end is the plane structure 4. The other end of the hole-like structure 2 and the plane structure 4 is the process section 1; The diameter is slightly smaller than the outer diameter of the helical winding section 3. The length of the hole-like structure 2 depends on the size of the winding helix clamp, which is generally 15mm-20mm. The hole-like structure 2 is provided with a through hole, and the axis of the through hole is the same as The axes of the hole-like structure 2 intersect vertically; the outer diameter of the plane struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com