Fixing clamp for circuit board welding

A technology for fixing fixtures and circuit boards, used in printed circuits, welding equipment, auxiliary welding equipment, etc., can solve the problems of single fixture fixing method, waste of resources, and inability to meet the diverse needs of circuit board design and shape, and achieve clamping and fixing. Good effect, convenient welding work, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

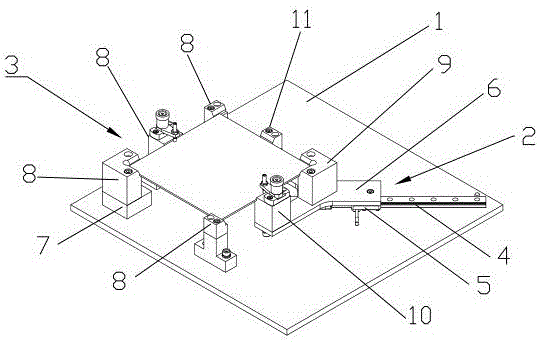

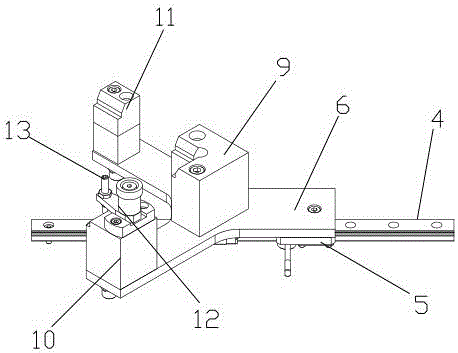

[0020] Such as Figure 1 to Figure 2 As shown, a circuit board welding fixing fixture includes a base and a fixture device, the fixture device is arranged on the base, the fixture device includes a movable assembly and a fixed assembly, the movable assembly includes a guide rail, a slider and a fixed plate, and the guide rail is fixedly arranged on the On the base, there is a slider on the guide rail, the slider is connected to the fixed plate, and the fixed plate is provided with a movable clamping block. The fixed component includes a fixed seat and a fixed clamping block. The fixed seat is fixed on the base. Equipped with fixed clamping block. When it is necessary to fix the circuit board, first place the circuit board on the fixed clamping block, then push the slider to move on the guide rail, let the movable clamping block act on the circuit board, so that the circuit board can be fixed, which is convenient for work The welding work of the circuit board is carried out by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com