Display module assembly and method for fixing circuit wafer thereof

A technology of display module and fixing method, applied in printed circuit parts, optics, instruments, etc., can solve problems such as increasing the cost of eliminating EMI materials, electromagnetic interference, and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

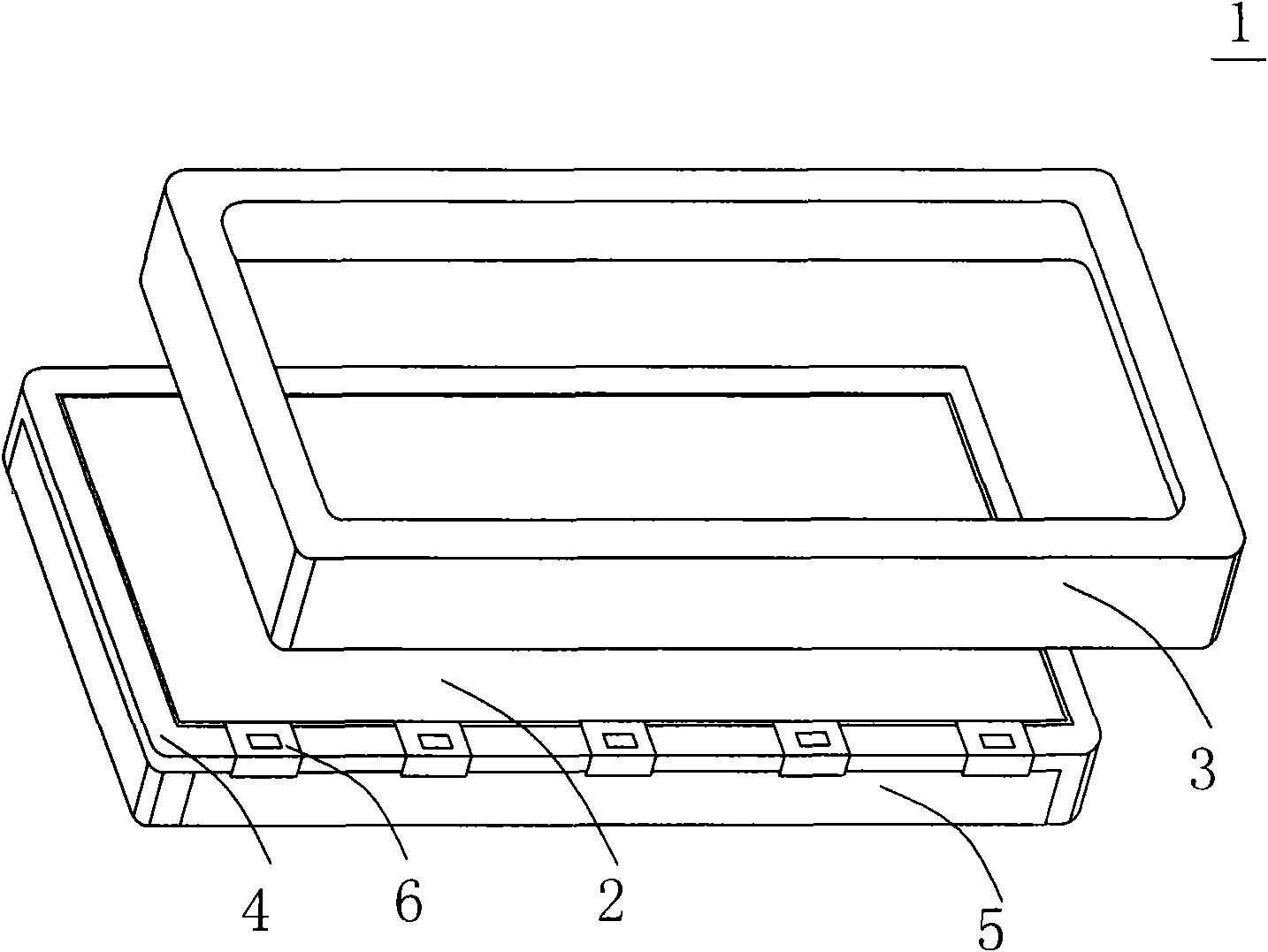

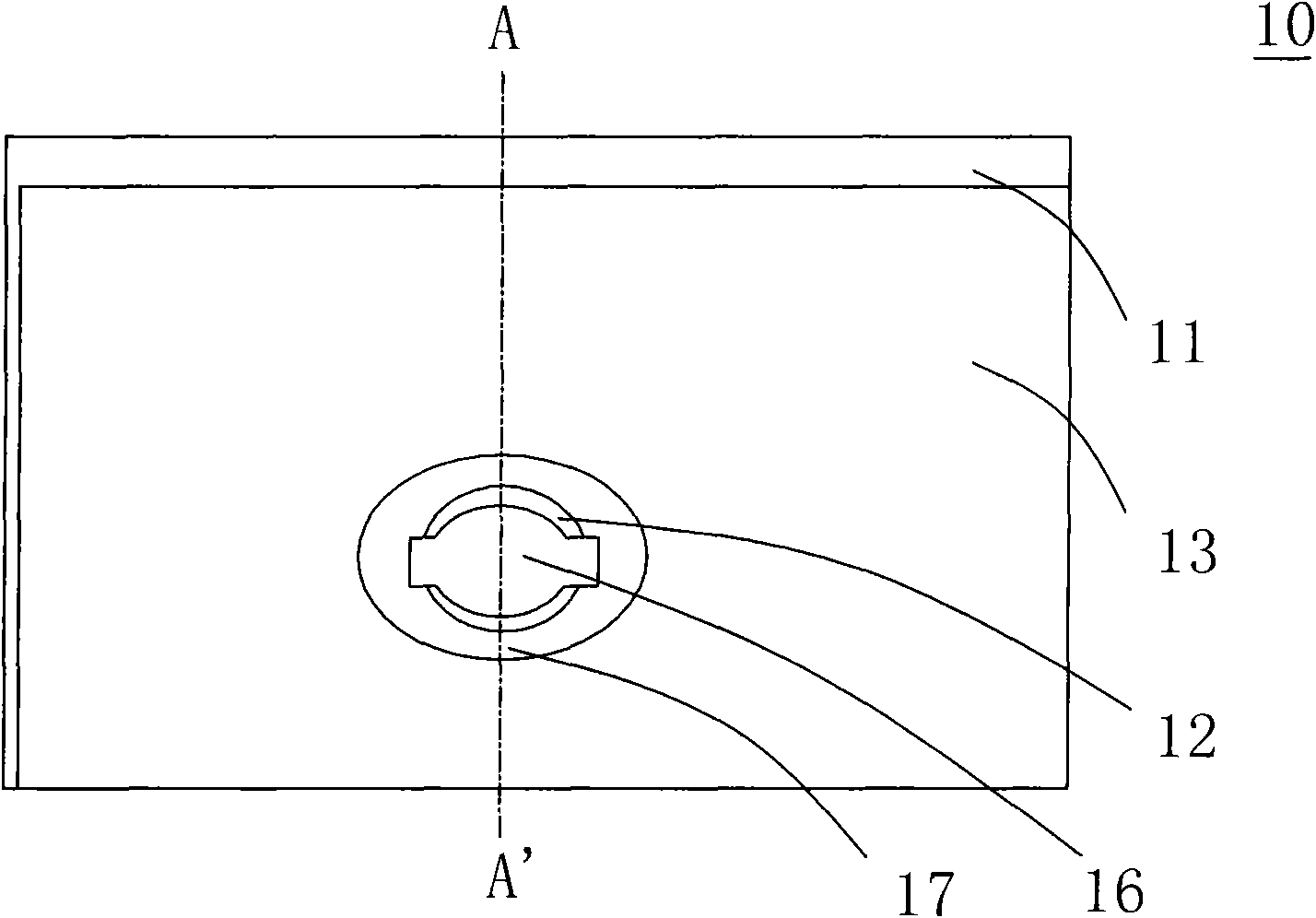

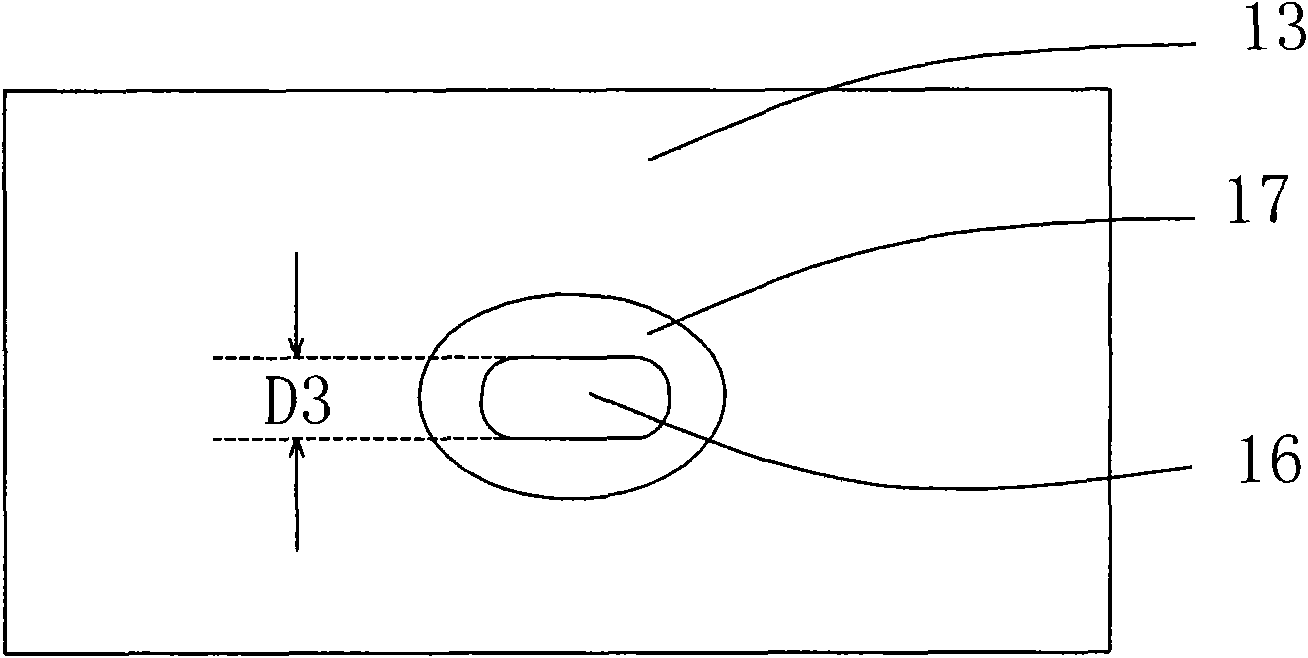

[0025] See figure 2 , image 3 with Figure 4 , figure 2 Shown is a partial schematic diagram of the display device according to the present invention, image 3 Shown is a schematic diagram of a circuit board according to the present invention, Figure 4 Shown as figure 2 A schematic cross-sectional view of the display device along the line A-A'. The display module 10 of the present invention includes a back plate 11, at least one fixing component 12 and a circuit board 13. Each fixing assembly 12 has a pair of connecting pieces 14 arranged on the back plate 11 and a pair of buckling pieces 15 respectively disposed on the connecting pieces, and the connecting pieces 14 of each fixing assembly 12 maintain a first distance D1, and The connecting members 14 of each fixing assembly 12 are adapted to be flexibly deformed in a manner of reducing the first distance D1. Wherein, the fixing component 12 is integrally formed with the back plate 11, or is made of the same material as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com