Vertical shaft TBM device

A shaft and cutter head technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of low construction efficiency of shafts, achieve reasonable force, improve efficiency, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

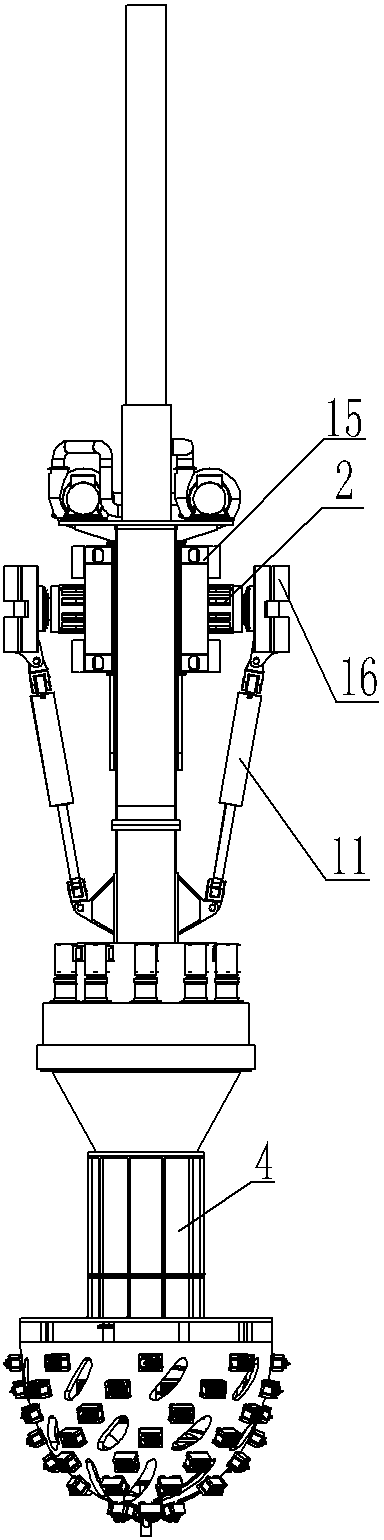

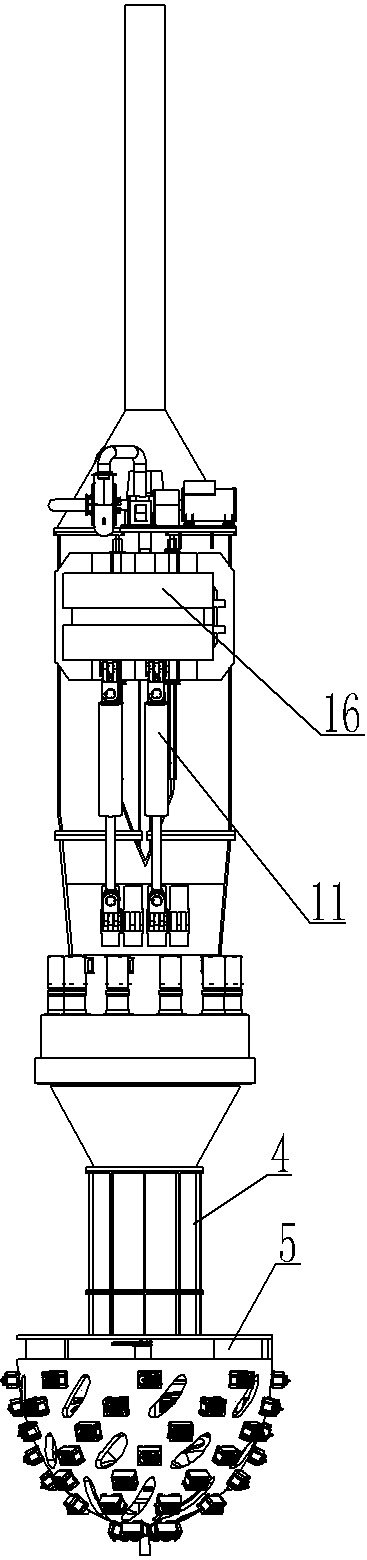

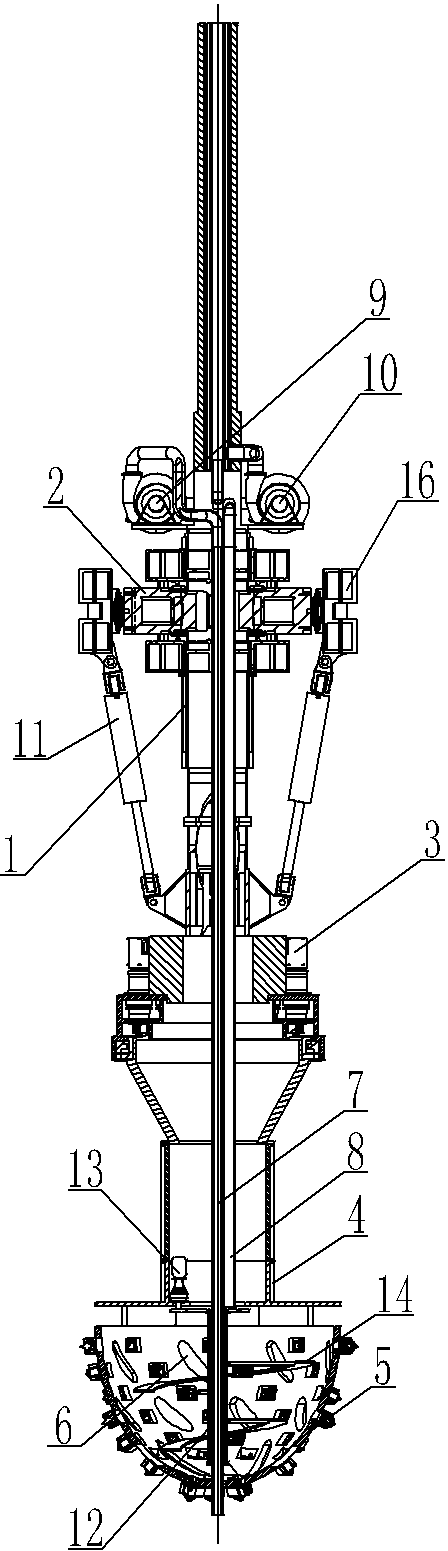

[0018] A kind of embodiment of shaft TBM device, in figure 1 , figure 2 as well as image 3 Among them, a cutter head drive system 3 is provided at the front of the main beam 1, where the cutter head drive system 3 is a gear drive system, which has a drive gear driven by a drive motor, and the drive motor is fixed on the main beam 1. The main bearing is fixed together with the rear portion of the connecting cylinder 4. In this way, the drive motor can drive the connecting cylinder 4 to rotate through the main bearing. A cutter head 5 is arranged at the front end of the connecting cylinder 4, where the cutter head 5 is half an ellipsoid, and the front end of the cutter head 5 is a sharper end of the ellipsoid. The inside of the cutter head 5 has a closed cavity, and a sealing plate is arranged at the rear end of the cutter head cavity, so that the cutter head 5 has a closed cavity. Cutters are arranged on the outer surface of the cutter head 5, and each cutter is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com