Fluidized bed garbage incinerator

A waste incinerator and fluidized bed technology, which is applied to fluidized bed combustion equipment, incinerators, fuels burned in a molten state, etc., can solve problems such as shutdown of the furnace and poor slag discharge of the fluidized bed waste incinerator , to achieve the effect of reducing the generated concentration, ensuring smooth slag discharge, and increasing the generated amount and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

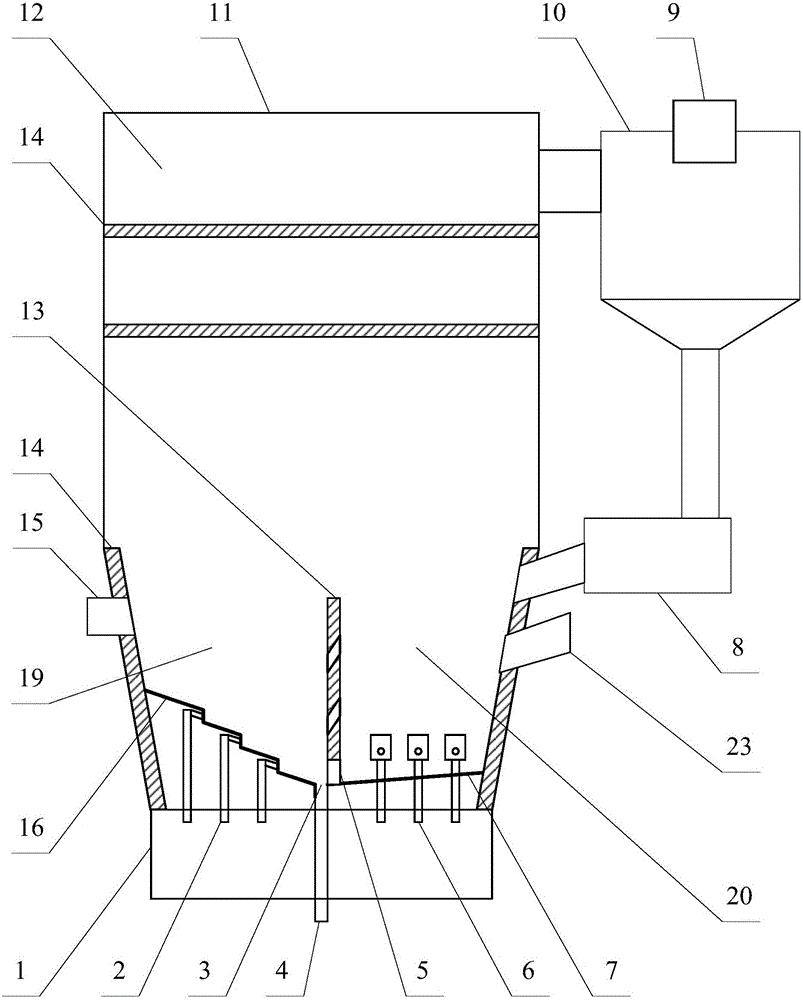

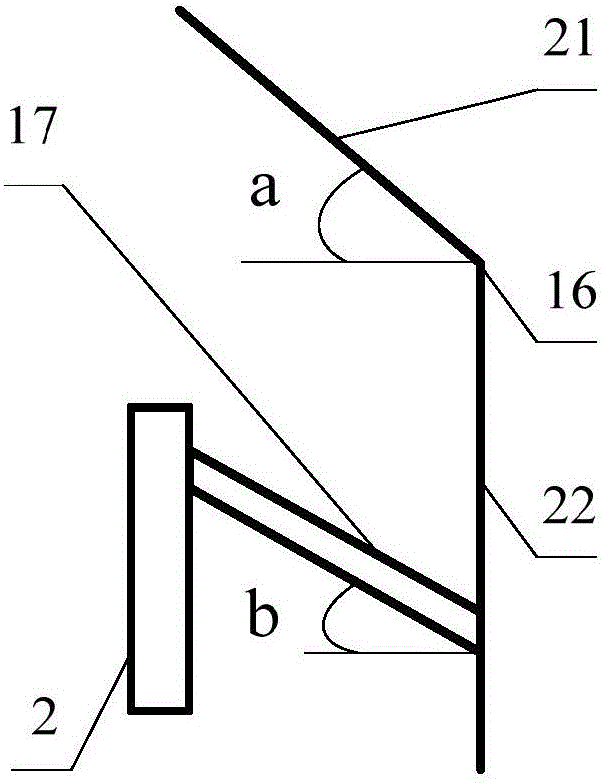

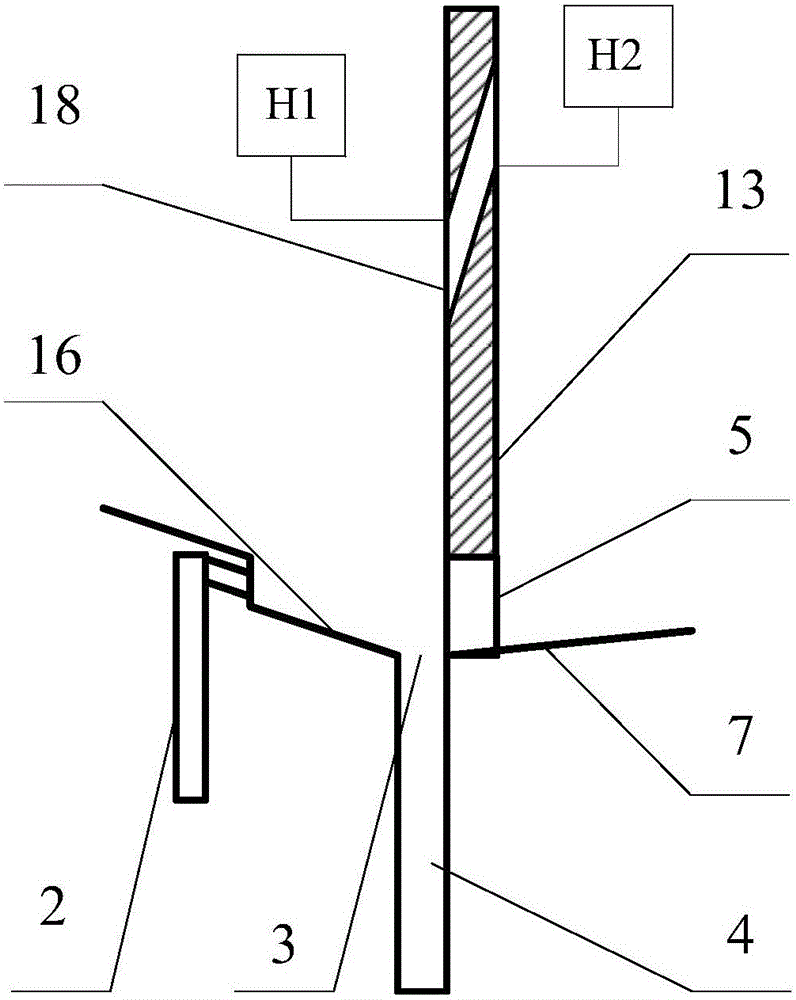

[0030] Such as figure 1 As shown, the present invention mainly includes a furnace 12, a partition wall 13, an inclined step-type air distribution plate 16, an air chamber 1, a directional air cap 2, an air cap 6, an air distribution plate 7, a feeder 8 and a separator 10.

[0031] Furnace 12 is surrounded by water-cooled wall 11 to form a sealed structure. Partition wall 13 is set at the bottom of furnace 12. Both sides of partition wall 13 are divided into slag discharge area 19 and fluidization area 20. Garbage inlet 15 is set in slag discharge area 19 and slag discharge area 19 The lower part is equipped with an inclined step-type air distribution plate 16, and the lowest position of the inclined step-type air distribution plate 16 is provided with a slag discharge port 3, and the inclined step-type air distribution plate 16 is provided with a directional air cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com