Slurry balance type tube push bench and circulative slurry deslagging method

A technology of mud-water balance and pipe jacking machine, which is applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/fittings, etc., and can solve problems such as low slag discharge efficiency and complex structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

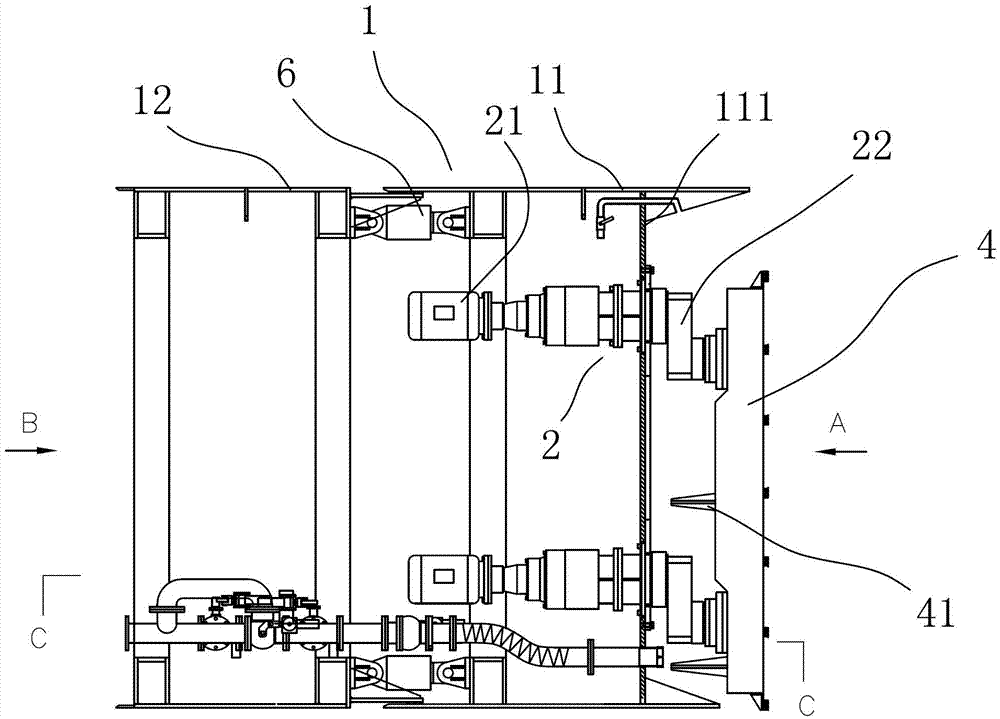

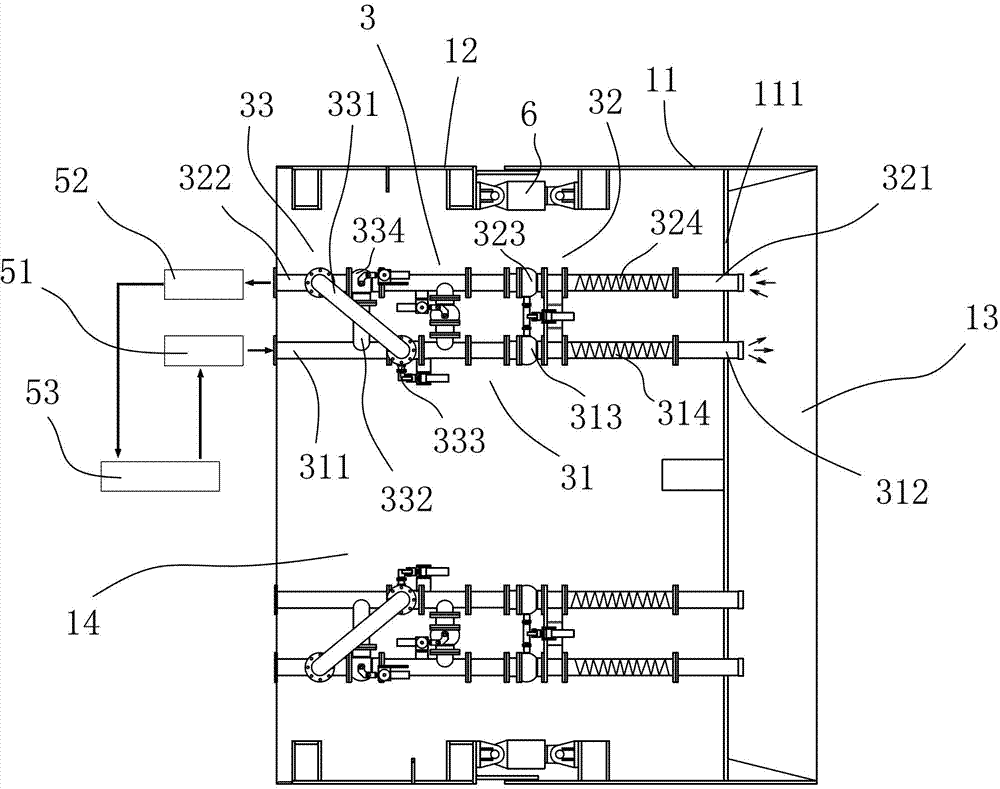

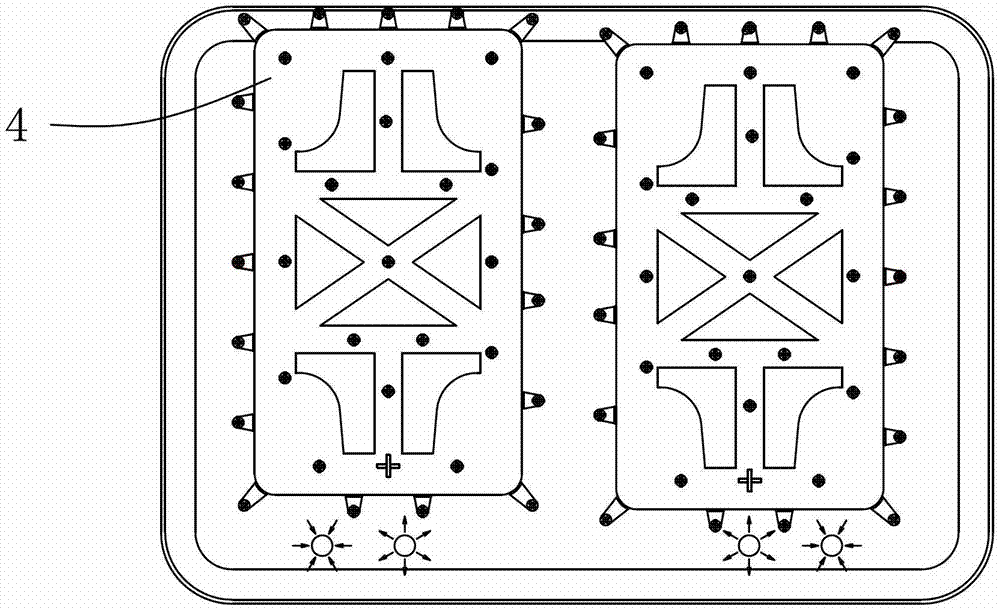

[0028] refer to Figure 1 to Figure 7 , a muddy water balanced pipe jacking machine according to the present invention includes a housing 1, the housing 1 includes a front housing 11 and a rear housing 12, and a deviation correction cylinder 6 is arranged between the front housing 11 and the rear housing 12, and the The front part of the front housing 11 is provided with a partition 111 that divides the inner chamber of the housing 1 into a muddy water chamber 13 and a machine inner chamber 14. In the machine inner chamber 14, at least one group of drive systems 2 and at least one group for The circular slag discharge system 3 for discharging the mud slag in the mud water chamber 13 , the output end of the drive system 2 is connected to the cutter head 4 through the partition 111 .

[0029] By installing at least one set of circulating slag discharge system 3 in the mud-water balanced pipe jacking machine, the sludge in the mud water cavity 13 can be circulated and slag-discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com