Engineering driller capable of efficiently discharging slag

An engineering drilling rig and high-efficiency technology, applied in the directions of rotary drilling rigs, drill bits, drill pipes, etc., can solve the problems of reducing the drilling efficiency of the drilling rig, increasing the labor intensity of workers, energy consumption, etc., to improve the slag removal efficiency, simple structure, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

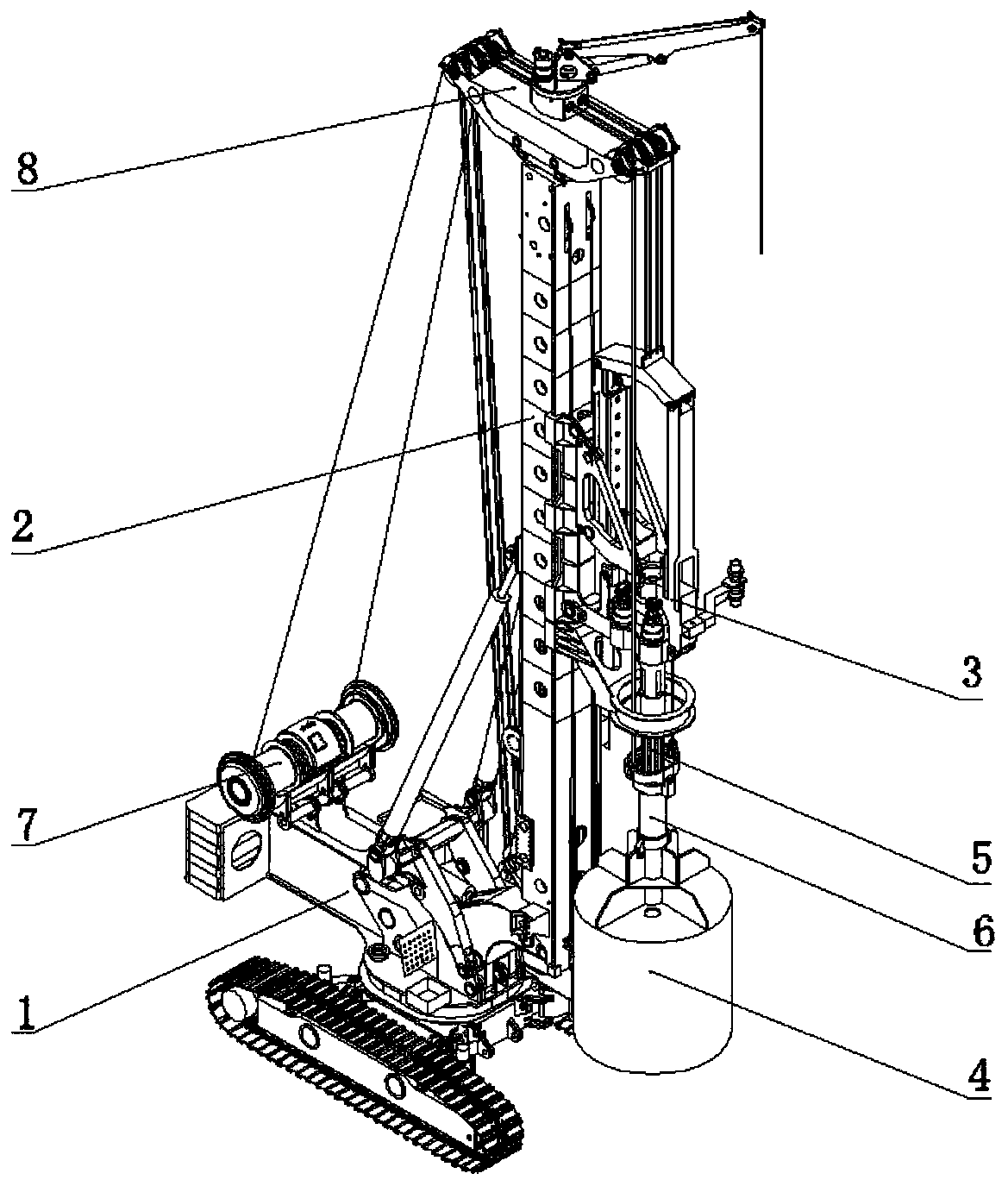

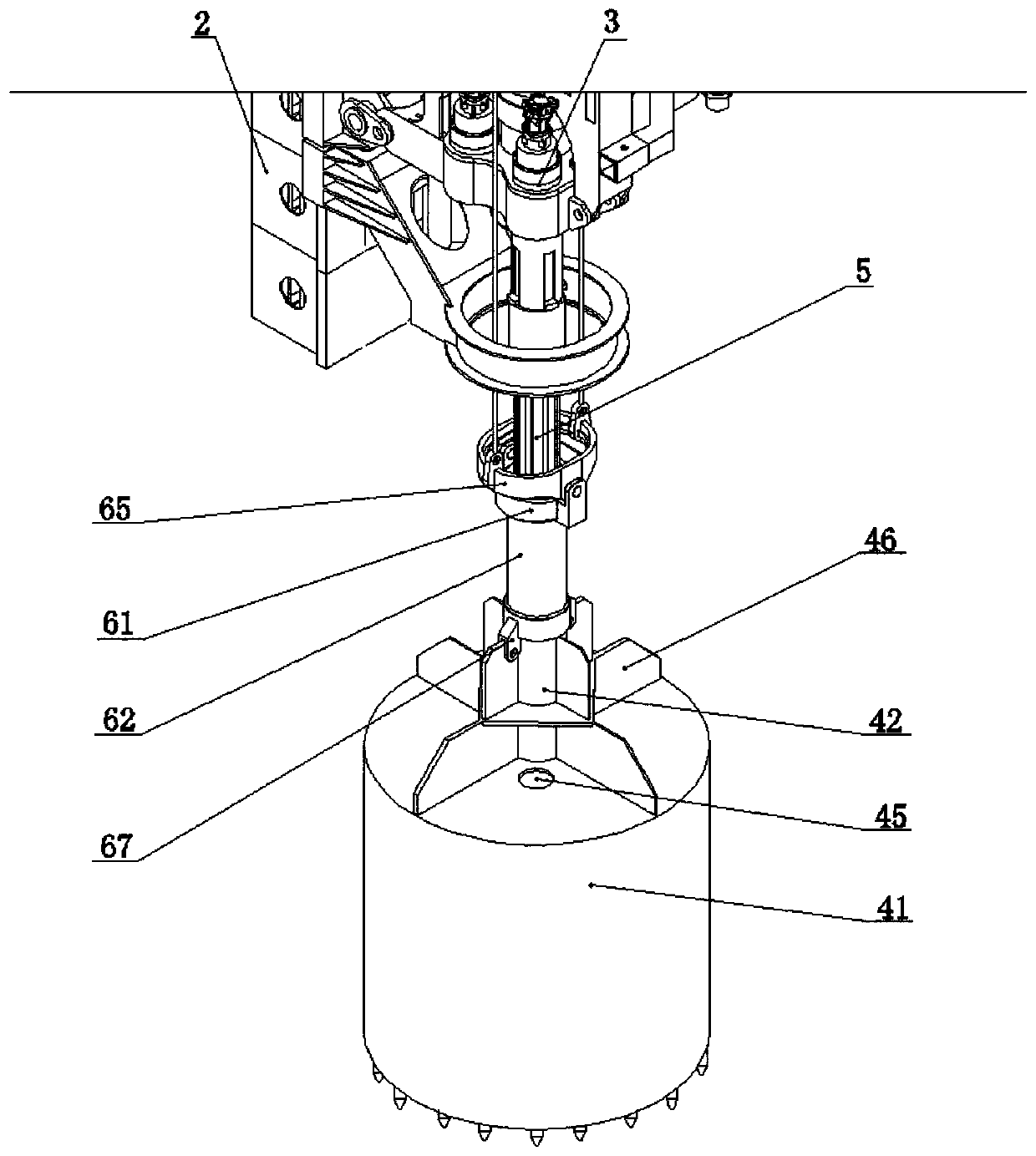

[0026] Embodiment 1, a kind of engineering drilling rig of efficient slagging, refer to figure 1 , including a drilling rig body 1, a drilling tower 2 is installed on the front end of the drilling rig body 1, a power head 3 is installed on the drilling tower 2, and a drilling tool assembly is installed on the power head 3, refer to figure 2 , the drilling tool assembly includes a rotary drilling bit 4, a drill pipe assembly and a slip ring assembly 6;

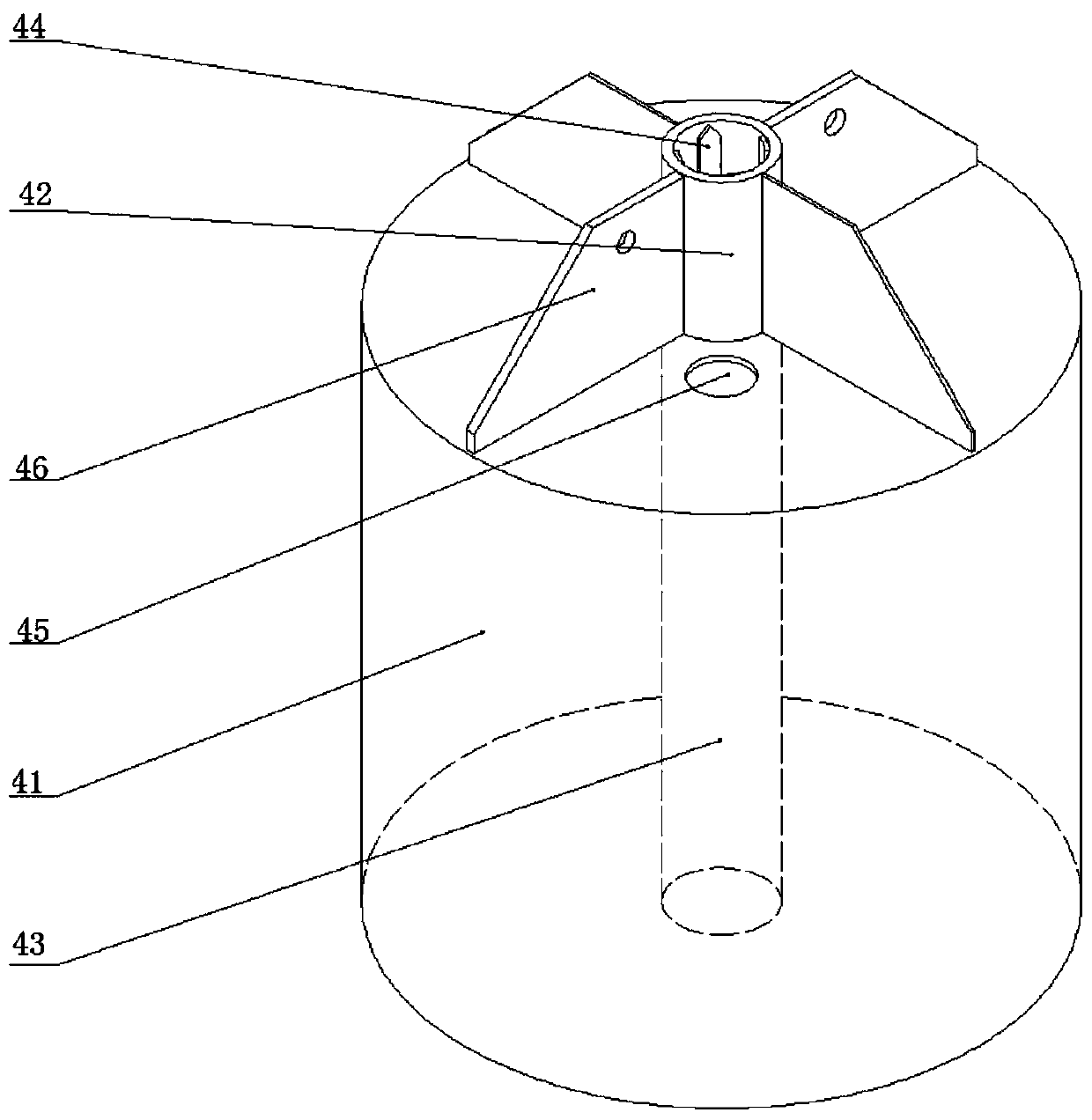

[0027] refer to image 3 and Figure 4 , the rotary drilling bit 4 includes a cylinder 41, the top of the cylinder 41 is provided with a loam cake, and the center of the loam cake is fixedly provided with a torsion transmission sleeve 42, and the torsion transmission sleeve 42 is fixedly provided with a torsion transmission inner spline 44, and the torsion transmission The axis of the sleeve 42 is collinear with the axis of the cylinder 41, and a sealing tube 43 connected to the lower end of the torque transmission sleeve 42...

Embodiment 2

[0031] Embodiment 2. In the high-efficiency slag discharge engineering drilling rig described in Embodiment 1: the bottom end of the sealing pipe 43 and the bottom end of the cylinder body 41 are at the same level.

Embodiment 3

[0032] Embodiment 3, a high-efficiency slagging engineering drilling rig described in Embodiment 1 or 2: the bottom of the cylinder 41 is fixedly equipped with drill teeth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com