Multi-cutter-disk heading machine

A roadheader and multi-cutter technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve problems such as unsatisfactory excavation of large-section tunnels, expand the scope of geological application, improve operating efficiency, and improve excavation efficiency and the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

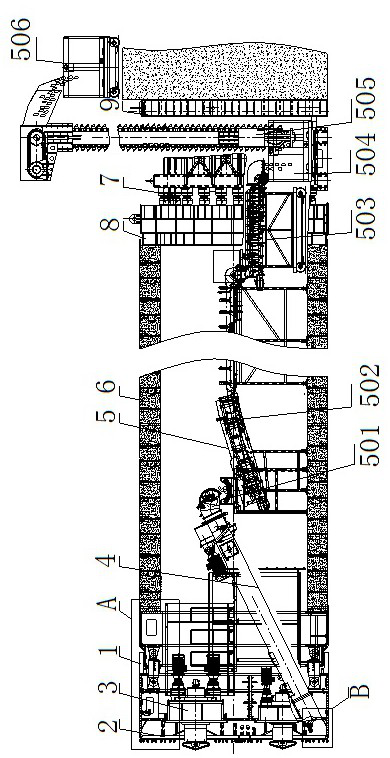

[0052] Embodiment 1, a kind of multi-cutter heading machine, such as figure 1 As shown, it includes an outer shell 1 that plays a supporting role. The front end of the outer shell 1 is provided with a drive system 3 connected to an excavation mechanism 2. The excavation mechanism 2 is equipped with a slag discharge system 4 and a slag conveying system 5 . The rear part of the outer shell 1 is provided with a jacking system 7, and the jacking system 7 cooperates with the outer shell 1 through the top iron 8 and the pipe joint 6 in sequence. Under the pushing action of the jacking system 7, the excavation mechanism 2 realizes the excavation of the face, and the excavated muck is transported to the muck conveying system 5 through the slag discharging system 4, and then conveyed by the muck conveying system 5. Drain the muck.

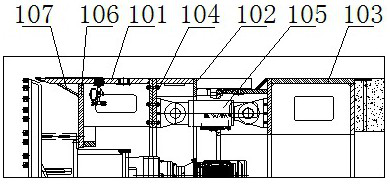

[0053] Specifically, such as figure 2 As shown, the outer casing 1 includes a front casing 101, a middle casing 102 and a rear casing 103 connected in ...

Embodiment 2

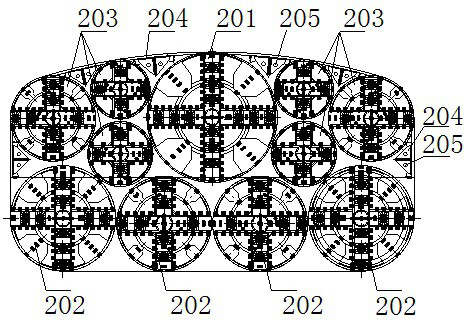

[0065] Embodiment 2, a kind of multi-cutter heading machine, such as Figure 7 As shown, the large cutterhead 201 and the medium cutterhead 202 are spoke-and-plate cutterheads, and the spoke-and-plate cutterhead includes radially arranged spokes and a faceplate. The small cutterhead 203 is a spoked cutterhead, and the spoked cutterhead includes radially arranged spokes.

[0066] Described large-scale cutterhead 201, medium-sized cutterhead 202, small-sized cutterhead 203 all comprise the big ring 206 that is arranged on outer beam outer end, and the circumferential direction of big ring 206 and described panel are all arranged with tearing knife 207, big circle The tearing knives on ring 206 act as gauge knives. A hob 208 and a scraper 209 are arranged on the spokes, and a central fishtail knife 210 is arranged at the centers of the large cutterhead 201 , the medium cutterhead 202 and the small cutterhead 203 .

[0067] Further, as Figure 8 As shown, a stirring rod 211 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com