Double-power quick connector screw drilling rod

An auger drill pipe and dual-power technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems that the threaded drill pipe can only rotate in one direction, high labor intensity, low slag discharge efficiency, etc., and achieve automation And intelligent, high slag discharge efficiency, easy drill back effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

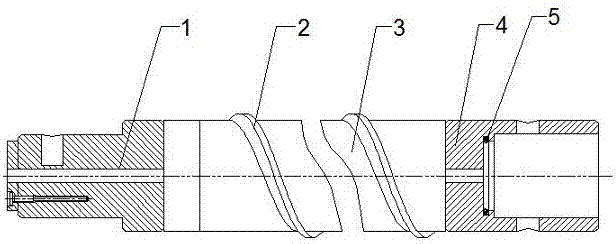

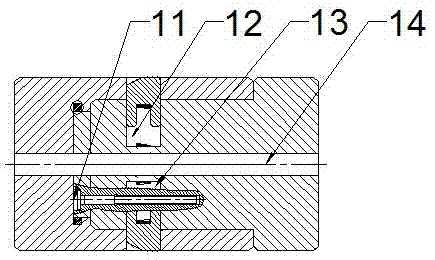

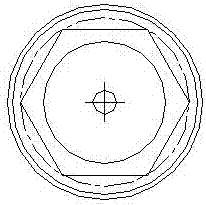

[0027] Such as Figure 1~6 As shown, a helical drill pipe with dual power quick joints includes a drill pipe main body 3, a helical blade 2 is arranged on the drill pipe main body 3, and a male joint 1 and a female joint 4 are respectively provided at both ends of the drill pipe main body 3; The main body of the connector 1 is a hexagonal prism with rounded corners on each edge of the end. The male connector 1 is provided with a first through hole 14 in the axial direction, and the middle part of the male connector 1 is symmetrically provided with a first blind hole 12 and a second blind hole 13. , for installing the deadbolt, the axes of the first blind hole 12 and the second blind hole 13 are perpendicular to the center line of the male joint, and the end of the male joint is provided with a third blind hole 11 and a fourth blind hole (not shown in the figure , set symmetrically with the third blind hole centering on the axis), used to install screws; the outside of the fema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com