Drilling equipment for coal seam large-diameter boring construction

A technology of large-diameter and drilling equipment, applied in drilling equipment and methods, drilling equipment, drill bits, etc., can solve the problems of inability to drill large-diameter holes and low drilling efficiency, so as to improve drilling efficiency and improve drilling efficiency. The effect of hole depth and guaranteed success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

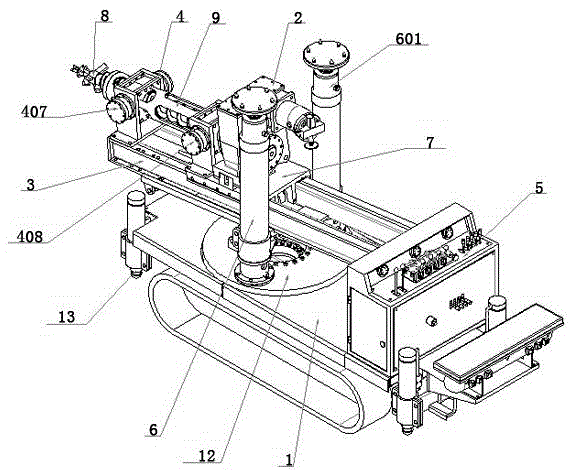

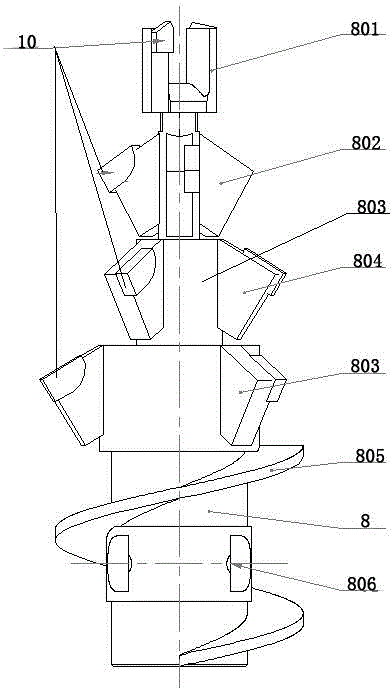

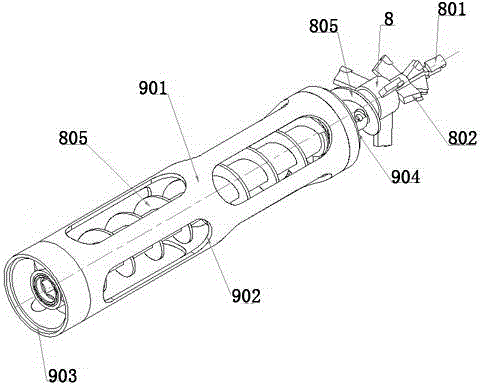

[0023] As shown in the figure, a kind of drilling equipment for large-aperture drilling in coal seams. The drilling equipment includes two parts, namely, a large-torque high-speed drilling rig and a drilling tool for large-aperture drilling in coal seams. The high-torque high-speed The drilling rig is composed of a crawler-type traveling mechanism, a supporting and fixing mechanism, a feeding mechanism, a power output device, a clamping mechanism and an operation console. The crawler-type walking mechanism can make the mobile drilling rig convenient and quick, and the drilling rig can be moved forward, backward and turned only by controlling the operating handle; the supporting and fixing mechanism plays the role of fixing the drilling rig when drilling, and the supporting and fixing mechanism is equipped with an oil cylinder. When the drilling rig is working, the oil cylinder is used to stretch out to withstand the rocks on the top plate and the bottom plate, and the drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com