Pulse plasma drilling machine system

A pulsed plasma and drilling rig technology, which is applied to drilling equipment, earth-moving drilling, drilling equipment and methods, etc., can solve the problems that the drilling rig cannot work normally, the position of the working coil is sensitive, and it is difficult to meet such requirements, etc. Achieve the effect of improving energy utilization efficiency and increasing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

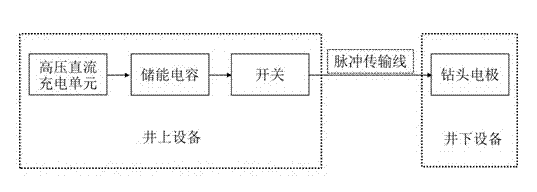

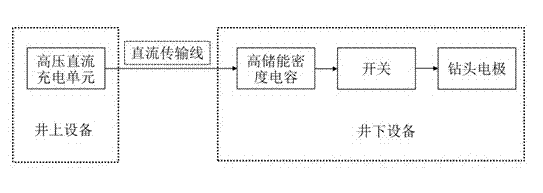

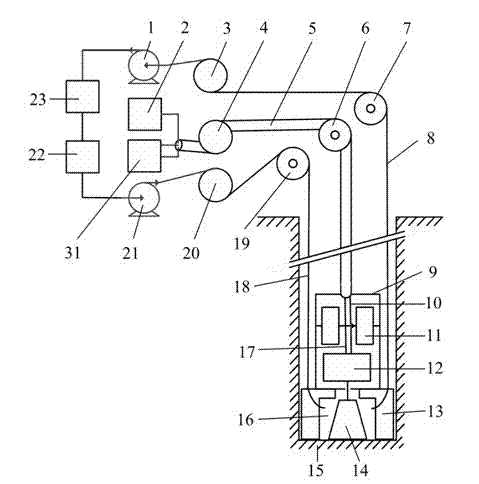

[0040] Such as figure 2 As shown, the circuit part of the pulse plasma drilling machine system of the present invention mainly includes a high voltage DC charging unit, a high energy storage density capacitor and a switch. Different from the traditional pulse plasma drilling rig system: the present invention places the high-voltage DC charging unit on the well, while the high energy storage density capacitor 11, the switch 12 and the drill bit electrodes are placed down the well. The uphole equipment (high-voltage DC charging unit) and downhole equipment (high energy storage density capacitor 11, switch 12 and drill bit electrodes) in the circuit part are connected together through a DC transmission line. see Figure 4 , as a specific implementation of the present invention, the three-phase alternating current is boosted by the transformer T and then rectified by the rectifier bridge to become a high-voltage direct current. This part is the high-voltage direct current chargi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com