High efficient gas extraction method of long drill hole directional segmental fracturing in soft and low permeability coal seam

A staged fracturing and gas drainage technology, which is applied in the direction of gas discharge, earthwork drilling, and mining fluids, can solve problems such as drill sticking, poor fracturing anti-reflection effect, and drilling depth limitation, and achieve increased drainage. The effect of improving the production area and efficiency, improving the efficiency of gas drainage, and increasing the scope of fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

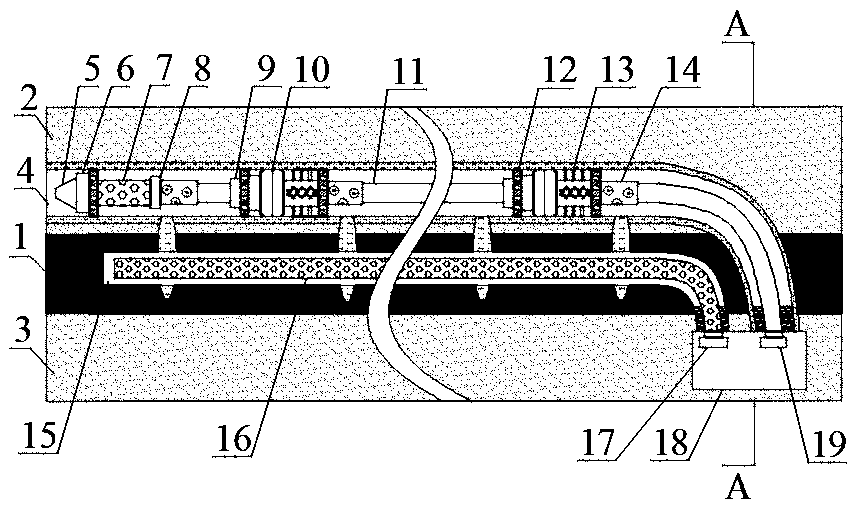

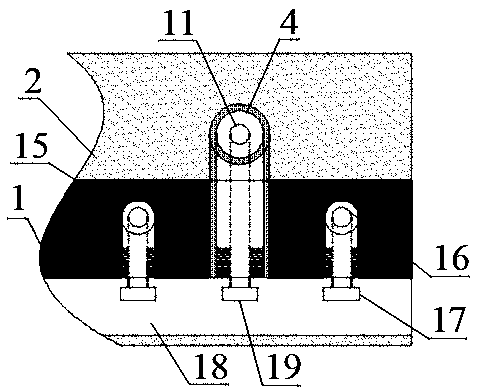

[0026] Attached below figure 1 and figure 2 , to further describe the specific implementation of the present invention in detail.

[0027] Such as figure 1 and figure 2 as shown,

[0028] A high-efficiency gas drainage method for directional segmental fracturing with long boreholes in a soft low-permeability coal seam provided by the present invention comprises the following steps:

[0029] S100~Excavate the floor rock roadway 18 in the floor rock layer 3 of the soft low-permeability coal seam 1, and drill horizontal fracturing holes 4 from the floor rock roadway 18 through the coal seam 1 to the roof rock layer 2 by using a kilometer directional drilling rig, and use boundary detection technology to control The horizontal fracturing hole 4 is in the roof rock layer 2 0.5-1.0 meters away from the top boundary of the coal seam 1, and the drilling length is 500-1000 meters.

[0030] S200~After the drilling of the horizontal fracturing hole 4 is completed, the drilling too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com