Steel tube drilling device provided with multiple drill heads

A drilling device and multi-drill technology, applied in positioning devices, driving devices, boring/drilling, etc., can solve problems such as low processing efficiency, time-consuming and labor-intensive, and accuracy-dependent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

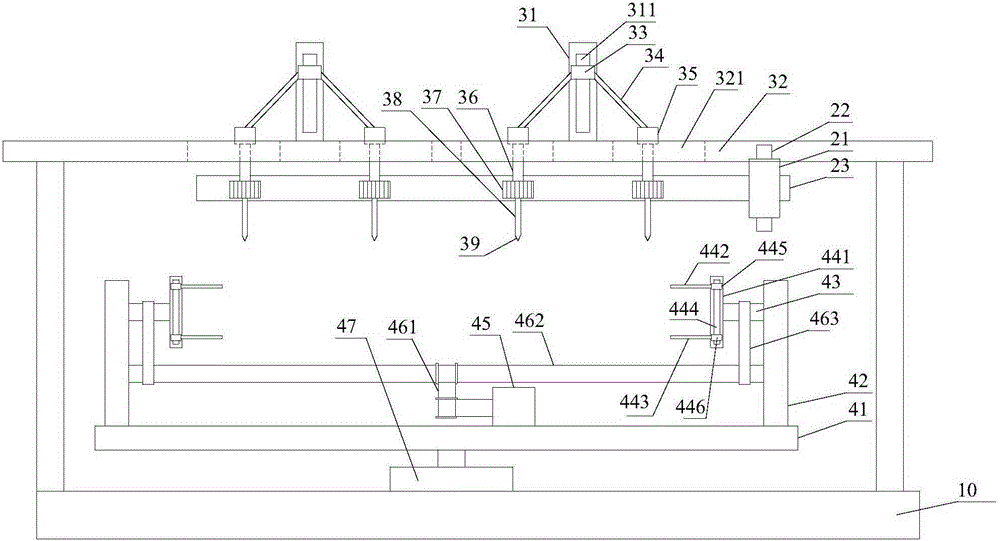

[0019] refer to figure 1 , the present invention proposes a multi-bit steel pipe drilling device, including a workbench 10, a driving mechanism, a drilling mechanism for drilling a steel pipe, and a clamping mechanism for clamping a steel pipe, wherein:

[0020] The driving mechanism includes a first gear 21 , a rack 23 , and a transmission shaft 22 , the transmission shaft 22 is fixedly connected to the first gear 21 , and the first gear 21 meshes with the rack 23 .

[0021] The drilling mechanism includes a plurality of drilling devices, and each drilling device includes a cross bar 32 installed on the workbench 10, a column 31 installed on the cross bar 32, a connecting plate 33 installed on the column 31 and two drills. Hole unit, each drilling unit comprises slide block 35, first connecting rod 36, second gear 37, drill rod 38; Column 31 is provided with the 3rd chute 311 along the direction perpendicular to workbench 10, connecting plate 33 and The third chute 311 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com