In-hole drilling tool integrating drilling, slotting and punching coal seam and using method thereof

A cutting and punching technology, which is applied in the field of anti-reflection and anti-collision, can solve the problems of hidden safety hazards and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

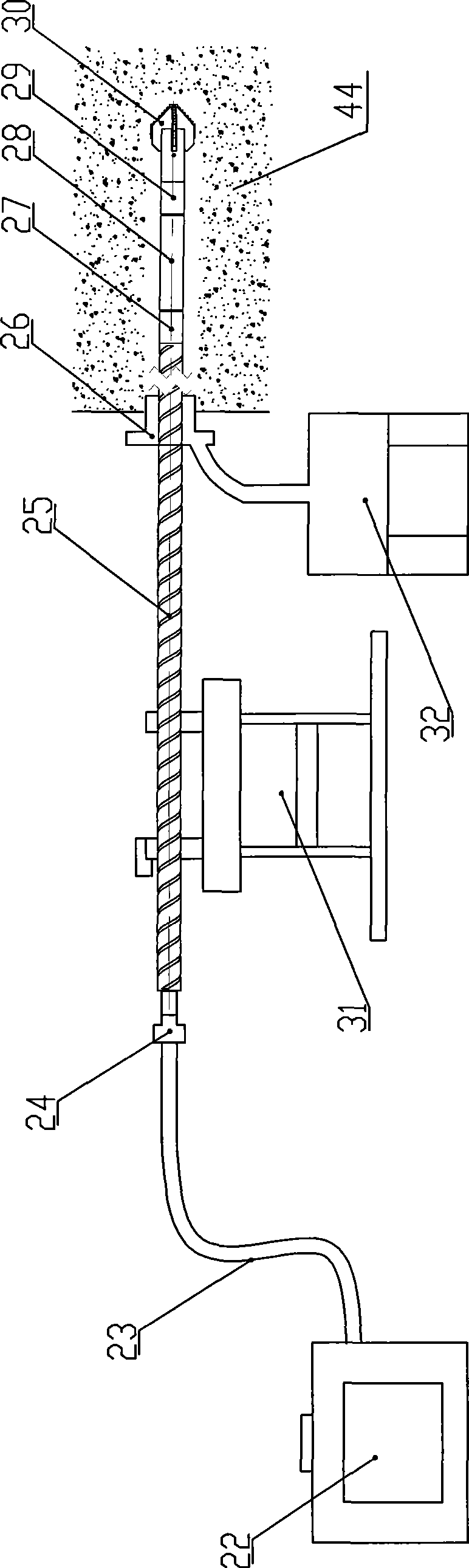

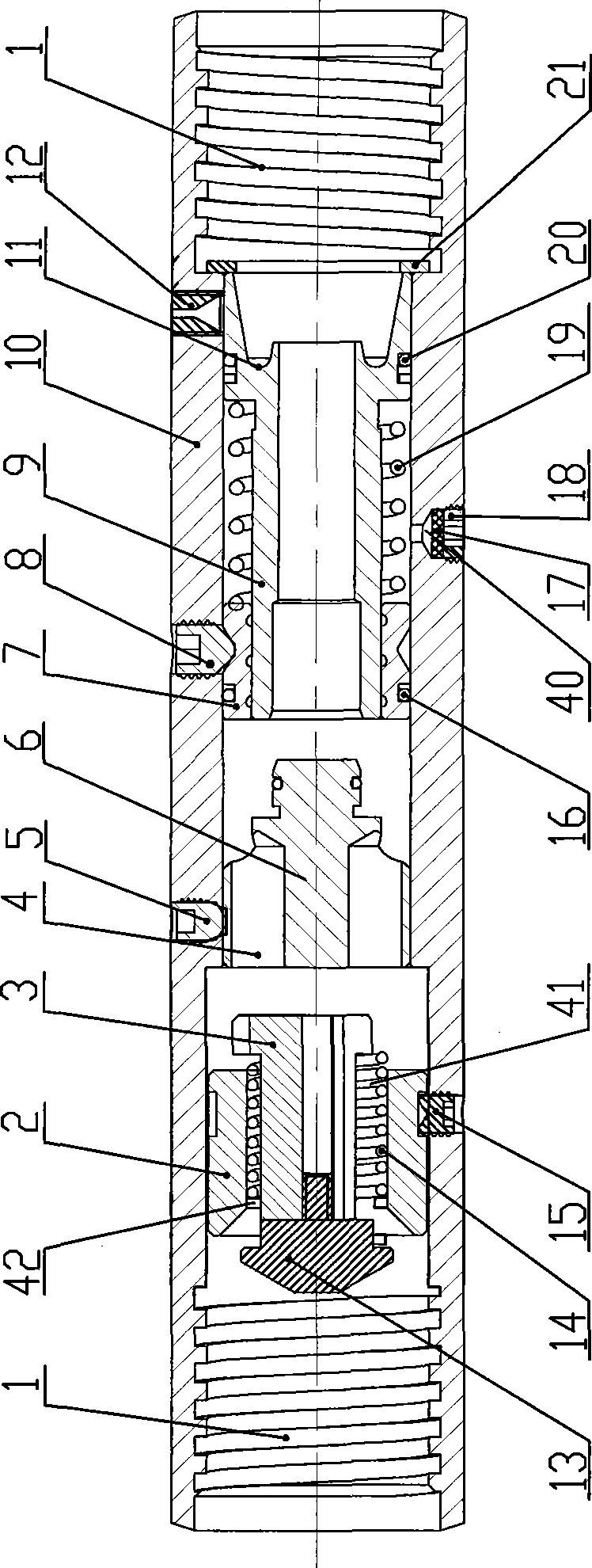

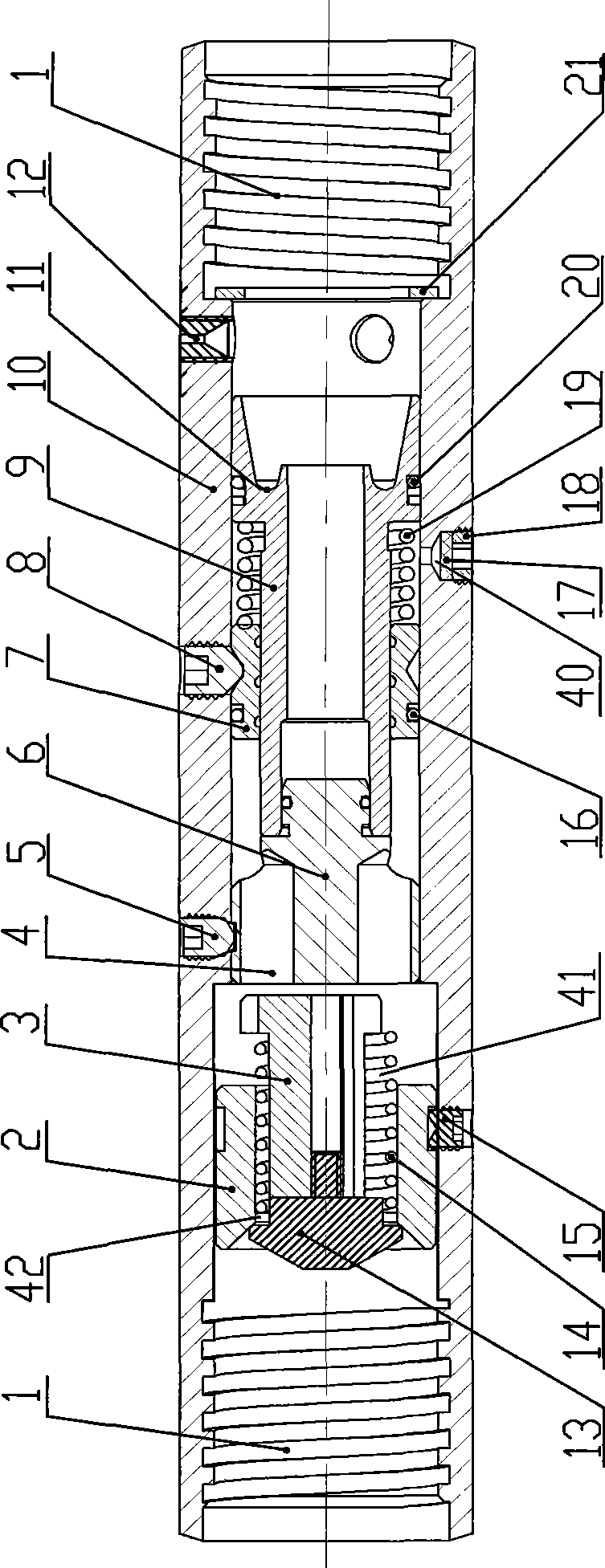

[0024] Such as Figure 1 to Figure 5 As shown, the coal seam drilling slit punching integrated hole drilling tool of the present invention and its use method include a drilling machine 31, a water supply or an air supply device, and the drilling machine 31 is provided with a high-pressure sealing drill pipe 25, a water supply or an air supply device Including high-pressure pumping station 22, hose 23 and water supply or air supply 24, one end of hose 23 is connected with high-pressure pumping station 22, the other end is connected with water supply or air supply 24, water supply or air supply 24 is connected with high-pressure The inlet of the sealing drill pipe 25 is connected, the front end of the high-pressure sealing drill pipe 25 is screwed with a slit punching valve 28 through a variable joint 27, the front end of the slit punching valve 28 is screwed with a drill bit 30 through a variable joint 29, and the high-pressure sealing drill rod 25. The slotting and punching va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com