Real-time drilling parameter and efficiency optimization method

An optimization method and drilling parameter technology, applied in drilling equipment, drilling automatic control system, earthwork drilling and production, etc., to achieve the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

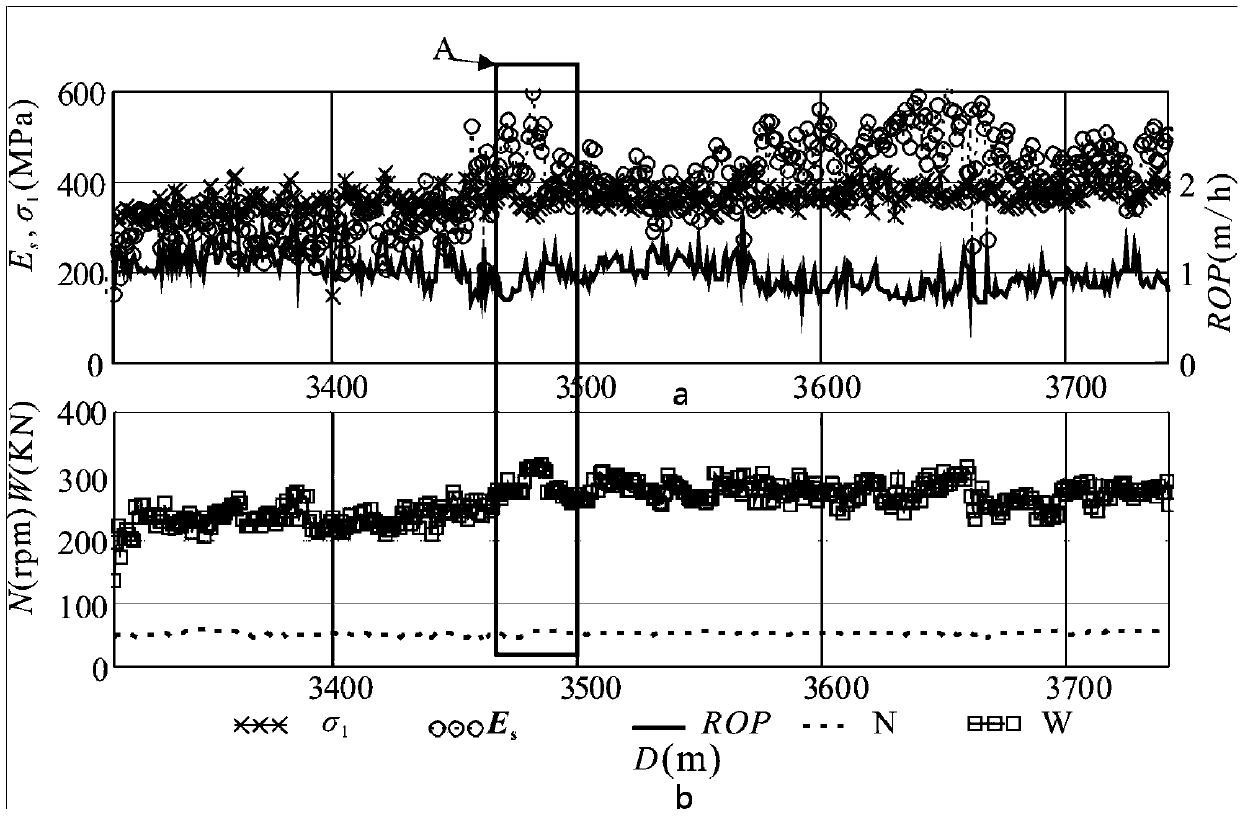

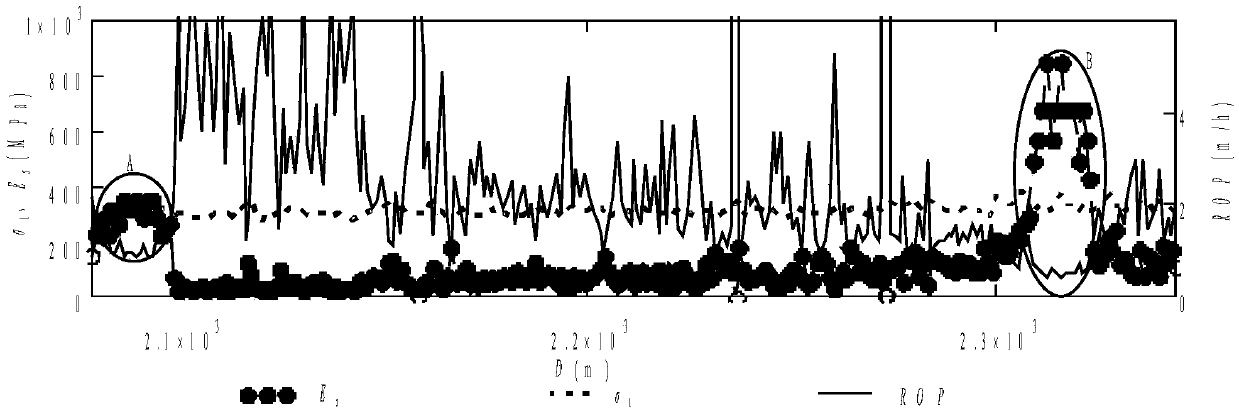

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

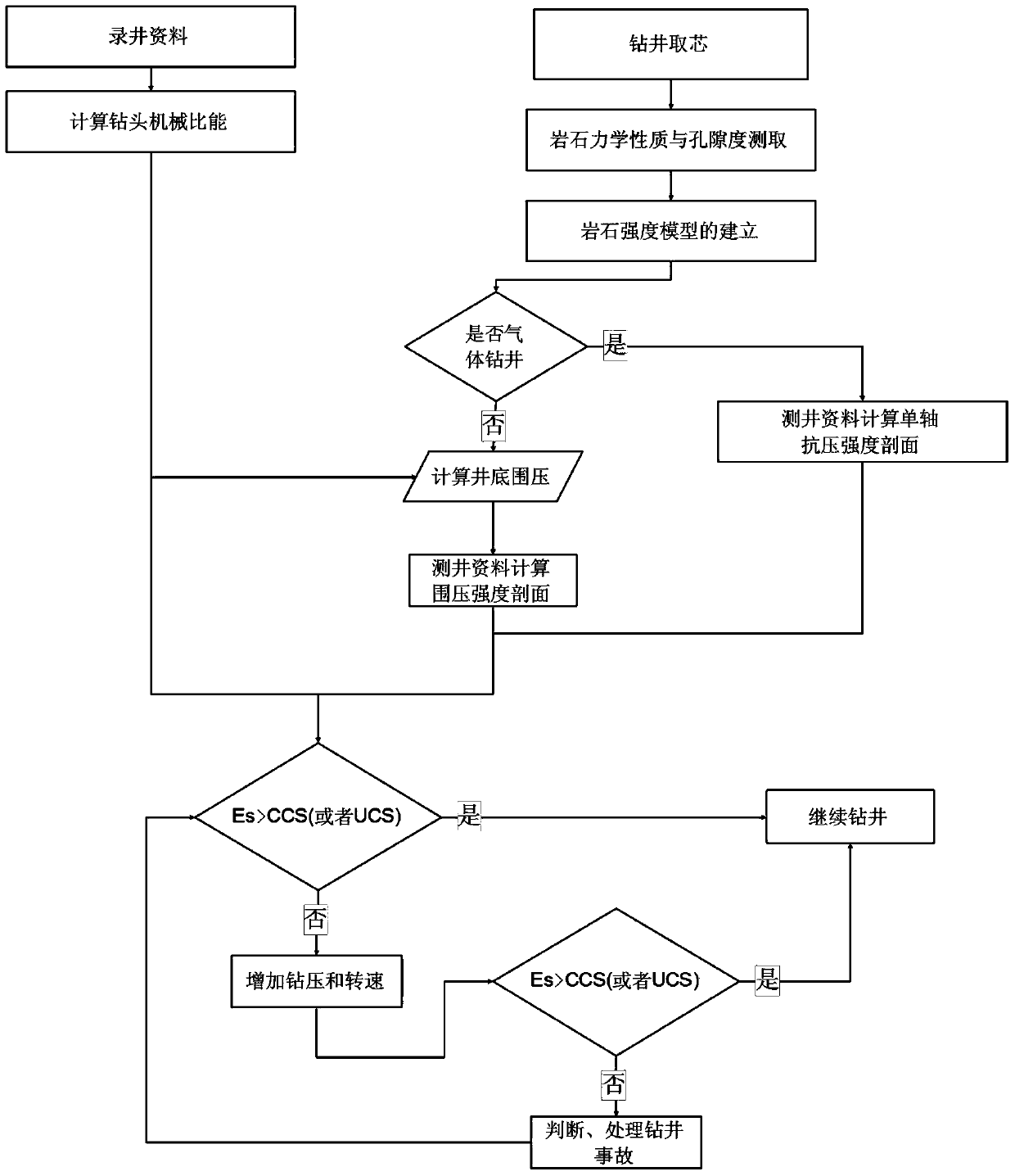

[0029] refer to figure 1 , a method for real-time optimization of drilling parameters and efficiency, comprising the following steps:

[0030] The establishment of the calculation model of rock strength at the bottom of A:

[0031] A1 collect rock cores with different porosities for a certain type of rock, and measure the porosity of the collected rock cores;

[0032] A2 Carry out triaxial rock mechanics experiments on rock cores with different porosities, and measure the compressive strength of rocks under different confining pressures;

[0033] A3 uses the particle swarm optimization algorithm to determine the parameters (a, b, c) in the intensity model:

[0034] σ 1 -σ 3 =UCS 0 (1+aσ 3 b )×exp(-φ×c)

[0035] where σ 1 is the triaxial compressive strength of the rock, σ 3 For the test confining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com