Turnover frame for stacked wooden boards

A technology of flipping racks and boards, applied in the field of flipping racks, can solve the problems of insufficient flipping efficiency, unsatisfactory use effect, and heavy wooden boards, and achieves the effects of reliable, fast and efficient flipping, ideal use effect, and high flipping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

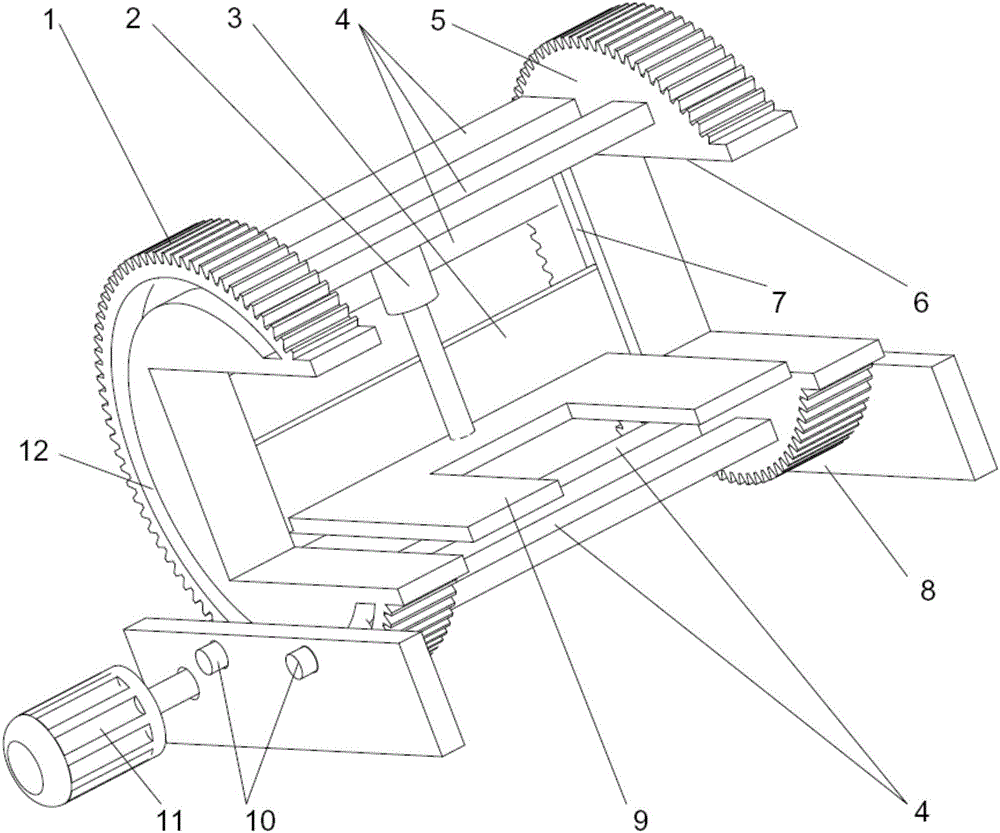

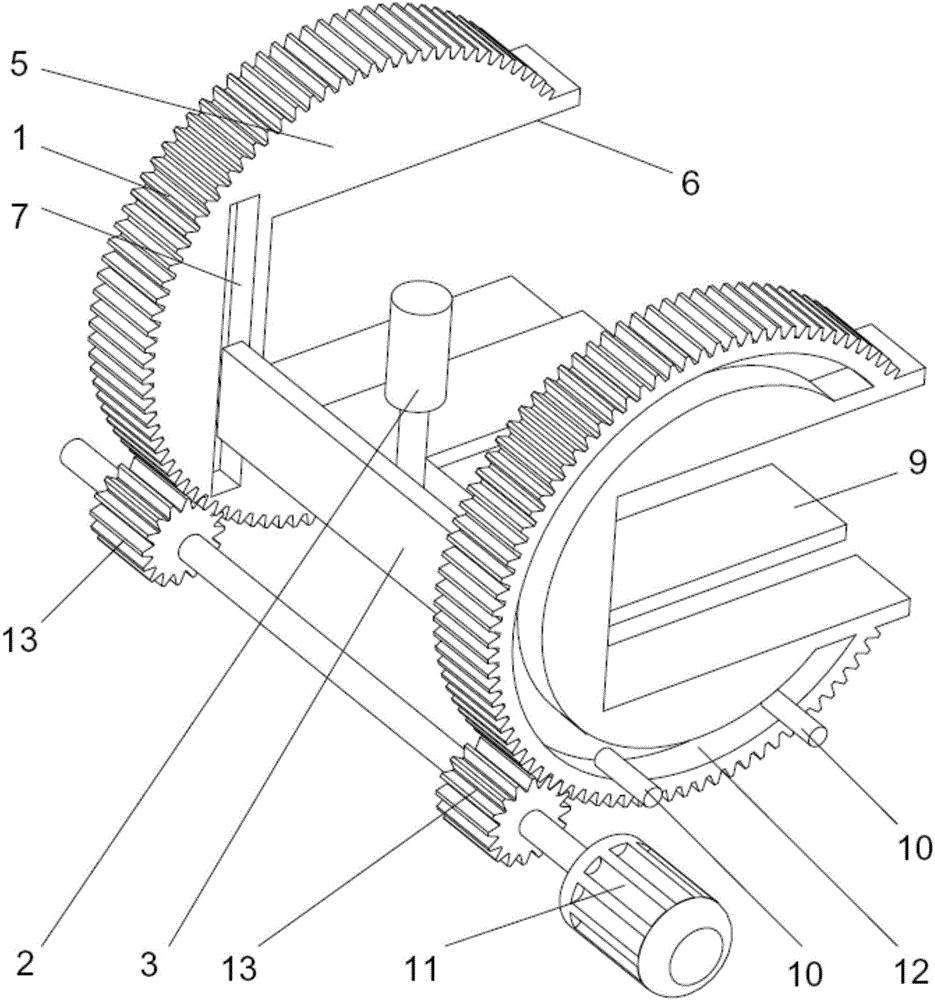

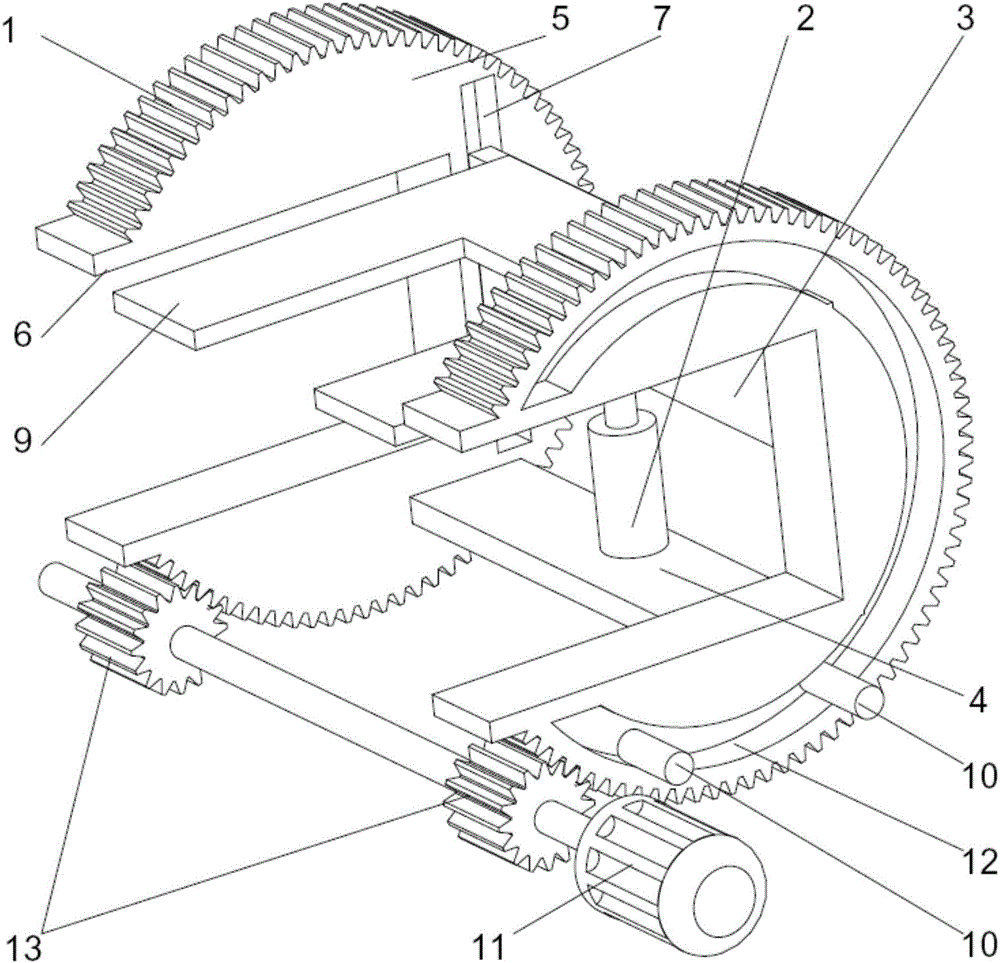

[0017] Embodiments of the present invention, such as Figure 1 to Figure 3 As shown, an overturn frame for laminated wooden boards includes two C-shaped wheel frames 5 that are movably erected on the base 8, and the back of the C-shaped bow of the C-shaped wheel frame 5 is an arc-shaped wheel surface. The wheel surface is provided with a wheel surface gear 1; the C-shaped recess is a square notch-shaped wheel frame gap 6; the opposite sides of the two C-shaped wheel frames 5 are provided with arc-shaped groove-shaped roller limit guide rails 12 ; Two C-shaped wheel frames 5 are provided with a rectangular guide groove 7 along the vertical edge of the wheel frame gap 6 on the opposite surface; The edges of the wheel frame gap 6 between the opposite surfaces are fixedly connected by a plurality of connecting rods 4; the two guide grooves 7 are inserted with movable clamps 3 that can move up and down, and the lower edge of the movable clamps 3 is vertically connected with movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com