Gypsum board defect automatic monitoring system and monitoring method

An automatic monitoring and gypsum board technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of complex design of the turnover mechanism, affecting the efficiency of the production process, and long conveying process, so as to reduce secondary damage Probability, improvement of turnover efficiency, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

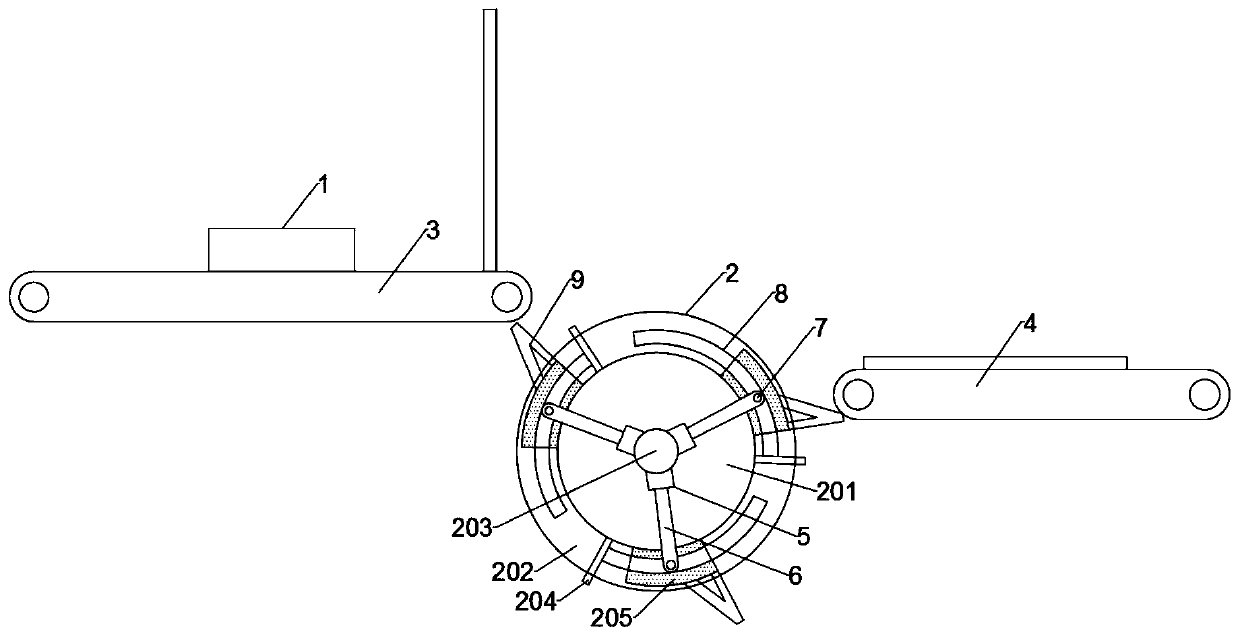

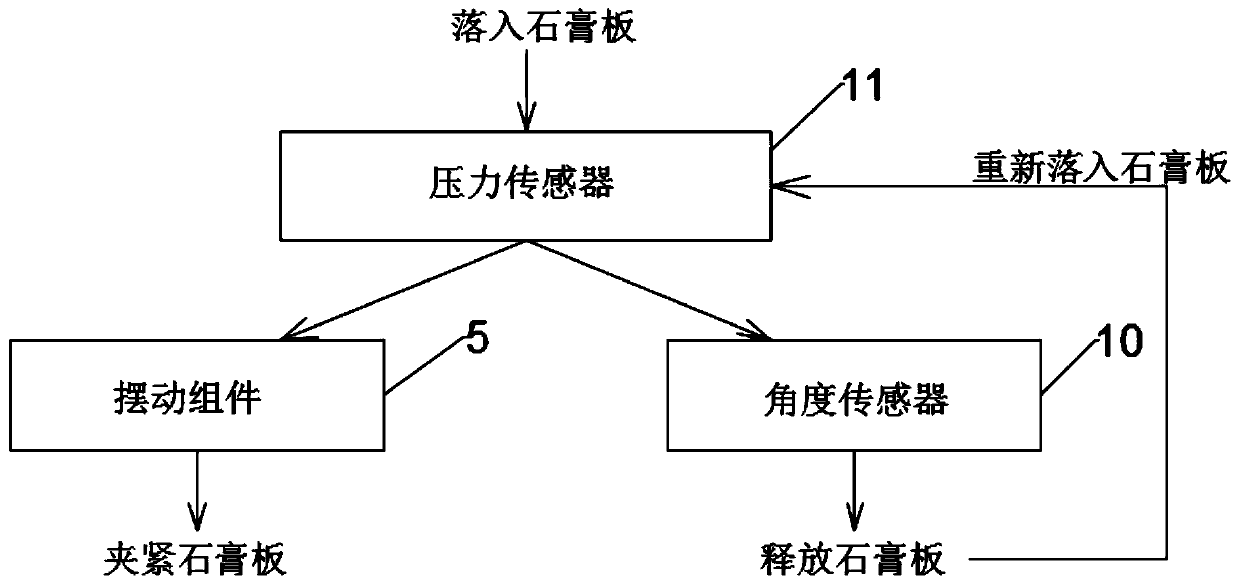

[0045] Such as figure 1 As shown, the present invention provides an automatic monitoring system for gypsum board defects. The gypsum board defect monitoring system in this embodiment is set between the output end of the dryer and the stacking station, and is mainly used to monitor the gypsum board defects of the dryer. Carry out quality inspection for damage and cracks. When the quality inspection is qualified and there is no damaged part, it will continue to be transported along the conveyor line to the stacking station for cutting. If the quality inspection is not qualified for damage, use the side of the gypsum board defect monitoring system The push mechanism is removed.

[0046] In order to quickly detect both sides of the gypsum board, the invention first stands the dry gypsum board sideways on the conveying line, and when the gypsum board reaches the defect detection area, two raster scanning devices can be used to complete the detection of the front and rear two gypsum...

Embodiment 2

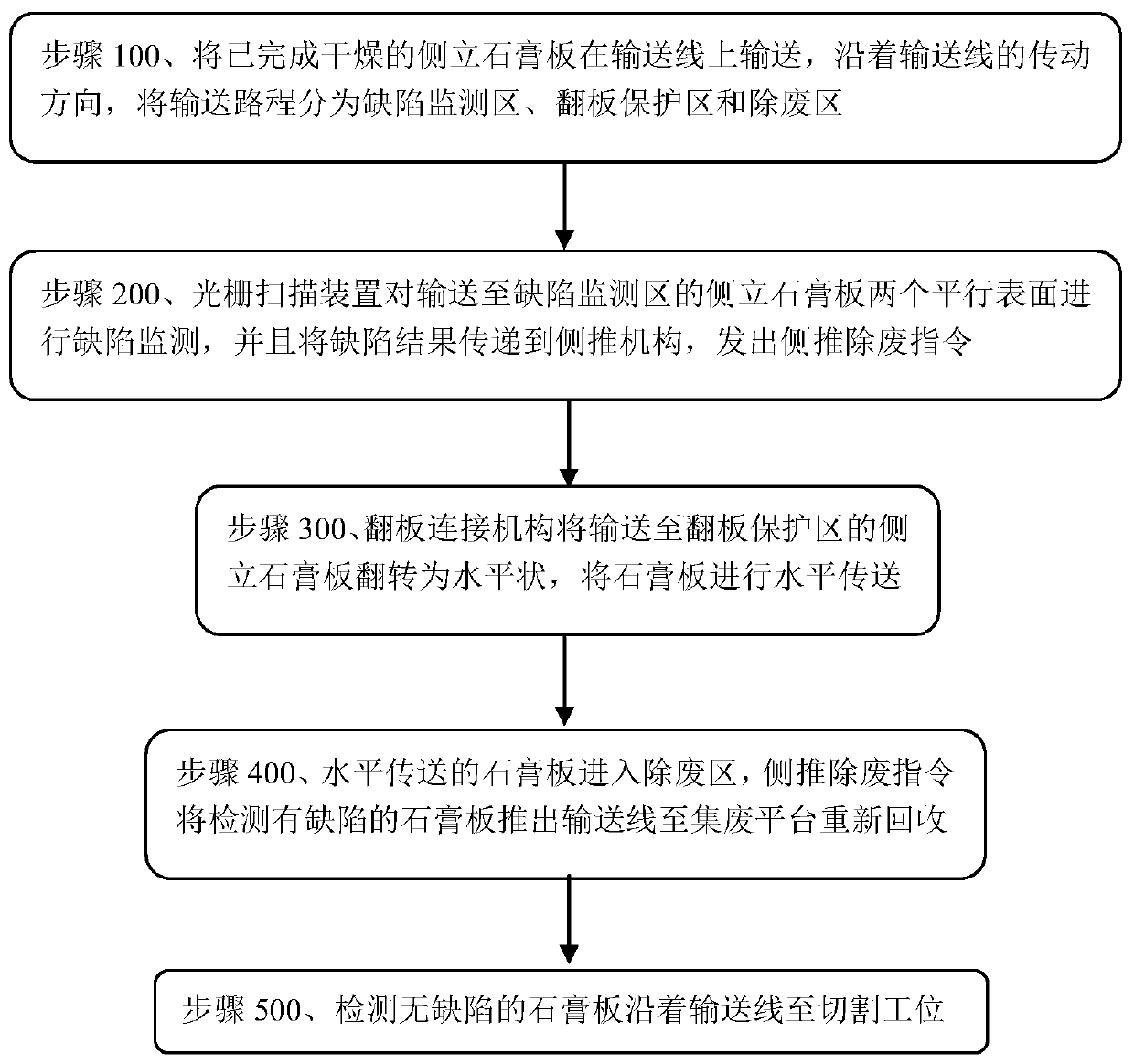

[0069] To illustrate the working principle of the above-mentioned automatic monitoring system for gypsum board defects, as image 3 As shown, the present invention also provides a monitoring method of a gypsum board defect automatic monitoring system, comprising the steps of:

[0070] Step 100, conveying the dried side-standing gypsum boards on the conveying line, and dividing the conveying distance into a defect monitoring area, a flap protection area and a waste removal area along the transmission direction of the conveying line.

[0071] The defect monitoring area is mainly used to detect whether there is any damage on the surface of the dried gypsum board. The flap protection area converts the detected gypsum boards standing sideways to horizontal transportation, which is convenient for the side pushing work of the damaged gypsum boards in the waste removal area, and stacking The work is carried out normally and quickly to prevent the secondary damage caused by the instabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com