Automatic-release riveting machine

A rivet machine and rivet technology, applied in the field of metal stamping, can solve problems such as hindering production efficiency, wasting enterprise production time, and increasing the workload of staff, so as to save production time, improve production efficiency, and reduce work burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

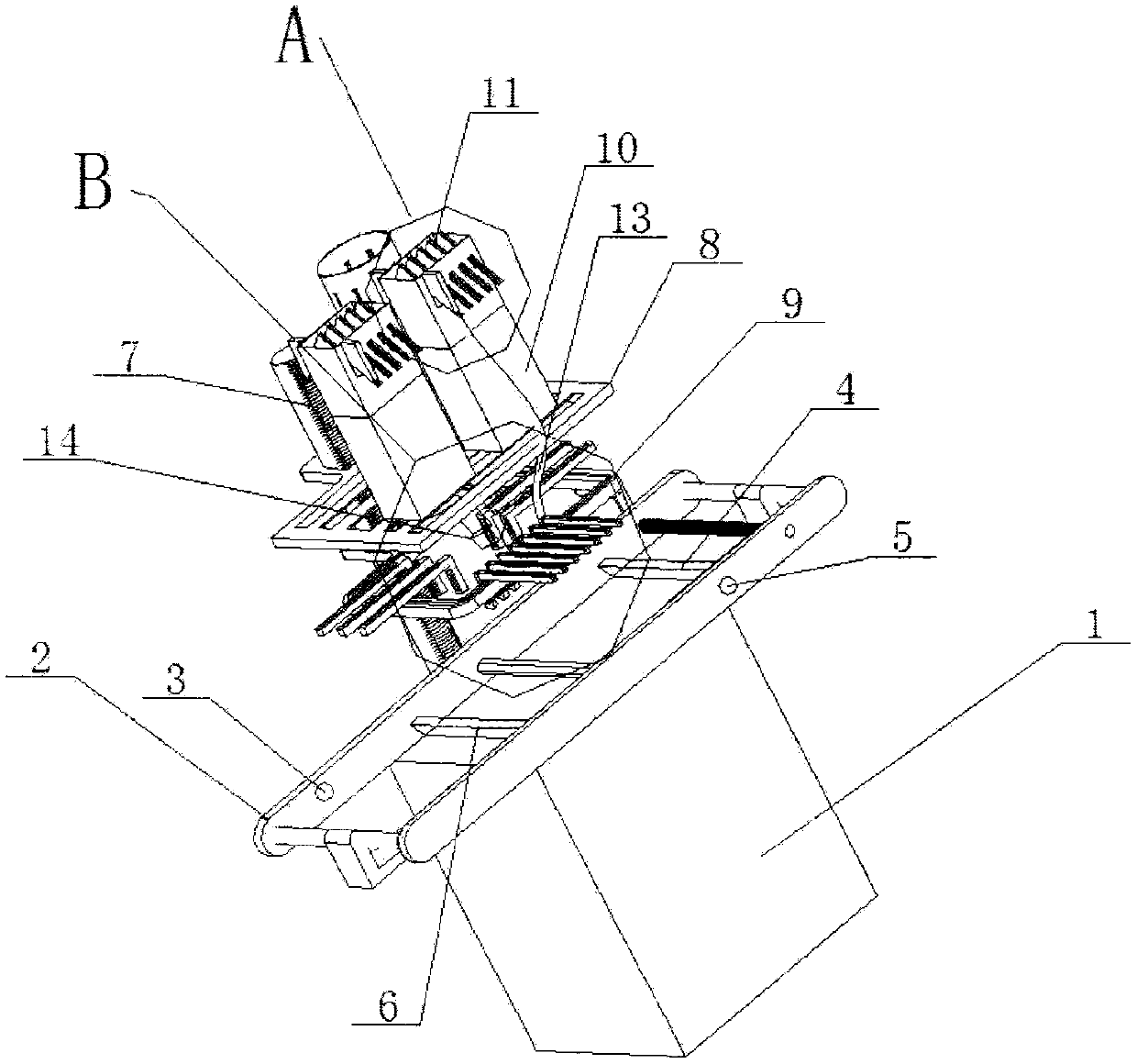

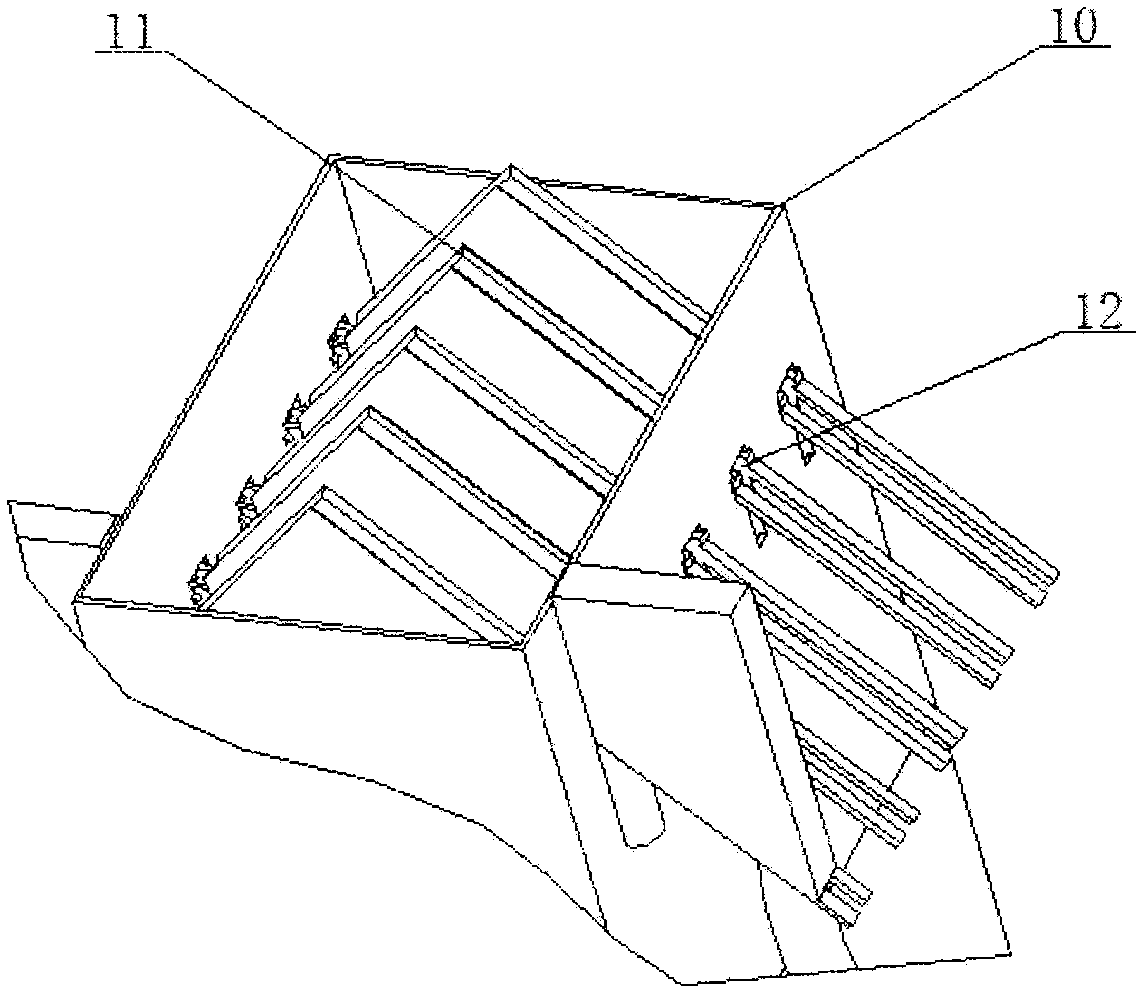

[0029] Such as figure 1 , figure 2 with image 3 As shown, the self-releasing rivet machine includes a base bracket 1, and a conveyor belt 2 is fixedly connected to the base bracket 1. The head end of the conveyor belt 2 is provided with a first sensor 3, and the first sensor 3 is connected to a first baffle 4. The first The baffle plate 4 is connected with a second sensor 5, the second sensor 5 is fixedly connected to the conveyor belt 2, the second sensor 2 is connected with a second baffle plate 6, and the second baffle plate 6 is placed at the head end of the conveyor belt and the first baffle plate 4 between, and the first baffle 4 and the second baffle 6 can move back and forth along the conveyor belt 1, the first baffle 4 and the second baffle 6 can move up and down; one side of the base support 1 is fixedly connected with a pillar 7. The pillar 7 is fixed with an arrangement fixing frame 8 and a rivet collection device in turn from top to bottom. Both the arrangemen...

Embodiment 2

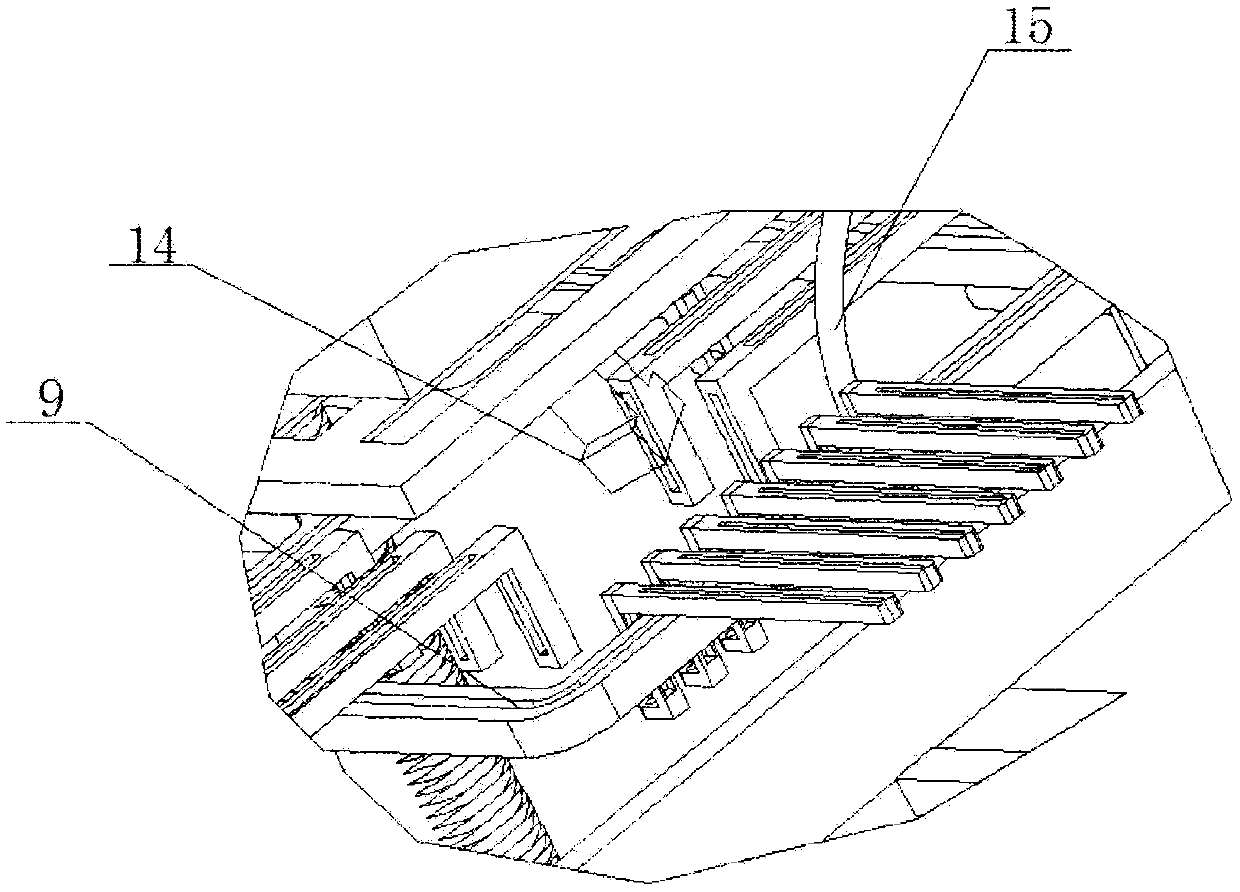

[0032] Such as figure 2 with Figure 4 As shown, the self-releasing rivet machine includes a base bracket 1, and a conveyor belt 2 is fixedly connected to the base bracket 1. The head end of the conveyor belt 2 is provided with a first sensor 3, and the first sensor 3 is connected to a first baffle 4. The first The baffle plate 4 is connected with a second sensor 5, the second sensor 5 is fixedly connected to the conveyor belt 2, the second sensor 2 is connected with a second baffle plate 6, and the second baffle plate 6 is placed at the head end of the conveyor belt and the first baffle plate 4 between, and the first baffle 4 and the second baffle 6 can move back and forth along the conveyor belt 1, the first baffle 4 and the second baffle 6 can move up and down, and the outside of the conveyor belt is fixedly connected with a positioning device 9, The top of the positioning device 9 is provided with a rivet placement device 14, and the rivet placement device 14 can realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com