Micro-fluidic chip bonding method and micro-fluidic chip

A microfluidic chip and bonding technology, which is applied in the field of bioscience micro-analysis system, can solve the problems of not being able to package the microfluidic chip firmly, and achieve the effect of reasonable structure, obvious bonding effect and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

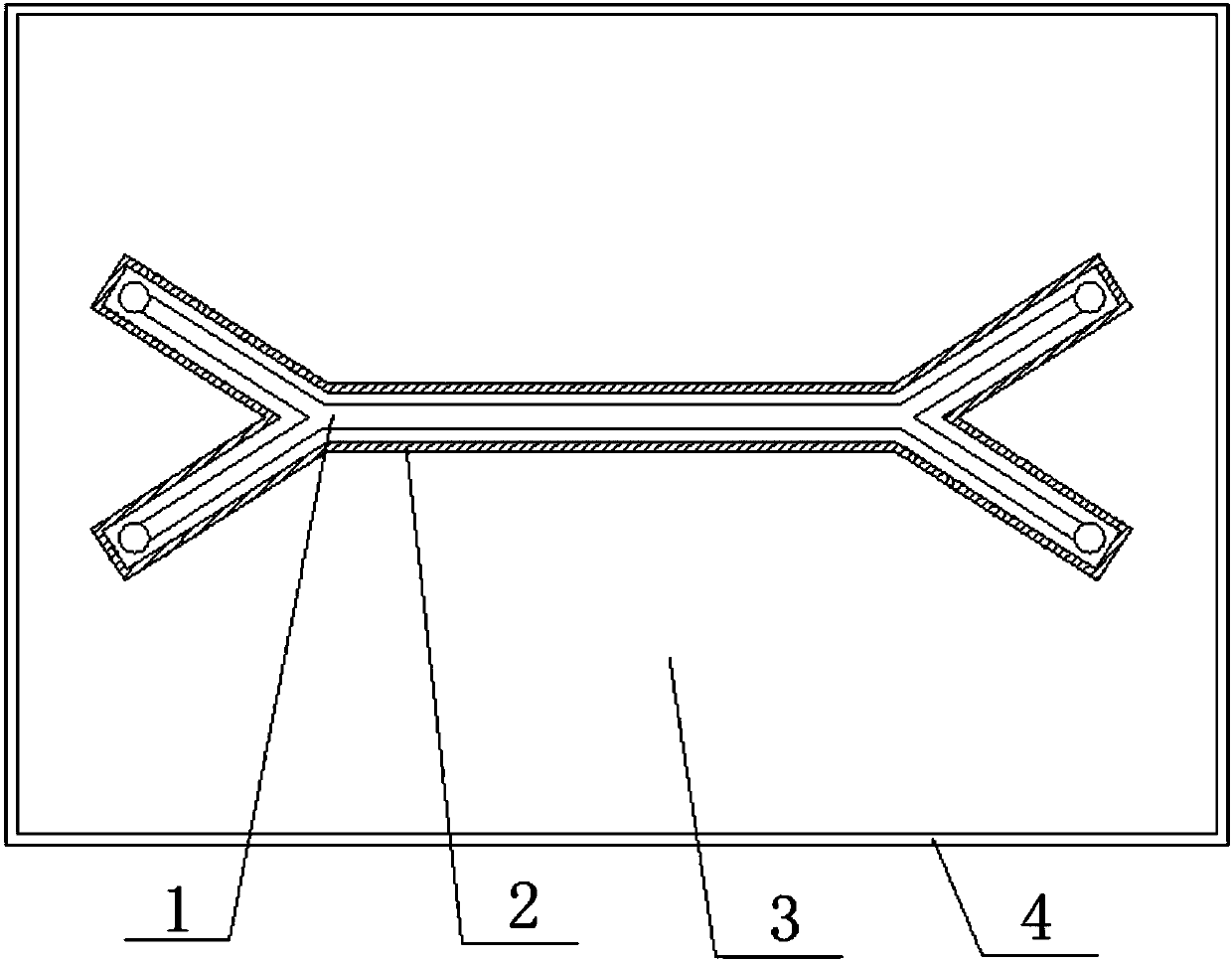

[0032] A microfluidic chip bonding method for bonding a substrate 4 with a microchannel structure 1 on the surface and a cover sheet together to form a microfluidic chip with a preset cavity structure, including:

[0033] Step 1, providing a microfluidic chip substrate 4, the upper surface of the substrate 4 is provided with a microchannel structure 1;

[0034] Step 2, setting ultrasonic bonding energy directors 2 at the periphery of the microchannel structure 1 on the upper surface of the substrate 4, the width and thickness of the ultrasonic bonding energy directors 2 are both 100-500 μm, more optimally, 200 μm is selected; the ultrasonic bonding energy director 2 cannot directly contact the edge of the microchannel structure 1, and is 100 μm-2 mm away from the edge of the microchannel structure 1, and more optimally, 200 μm is selected;

[0035] Step 3, paste double-sided adhesive tape 3 on the upper surface of the substrate 4, and bond the cover sheet to the substrate 4. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com