Preparation method for low-temperature curing structure glue film

A curing structure and adhesive film technology, applied in the direction of film/sheet adhesives, adhesives, epoxy glue, etc., can solve problems affecting efficiency, etc., to achieve improved performance, excellent bonding performance, and excellent bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] A low-temperature curing structural adhesive film, in parts by weight, its composition is as follows:

[0017] A component: 30 parts of TDE-85 epoxy resin, 25 parts of AG-80 epoxy resin;

[0018] B component: 45 parts of bisphenol F epoxy;

[0019] C component: 5 parts of polyetheramine, 6 parts of dicyandiamide;

[0020] Component D: 15 parts of core-shell rubber (MX-157), 15 parts of thermoplastic resin;

[0021] Component E: 3 parts of substituted urea, 1 part of DMP-30;

[0022] Component F: 2 parts of titanate, 2 parts of fumed silica.

[0023] The preparation method of this kind of low-temperature curing structural adhesive film is as follows:

[0024] Add component A, component B and component D into the mixing equipment, raise the temperature to 120 °C and keep stirring for 60 minutes to fully dissolve component D and mix evenly, add component F, keep stirring at 90 °C for 30 minutes, cool down to After 45°C, add components C and E, and keep stirring for 20...

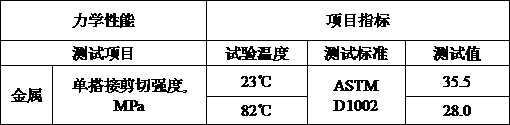

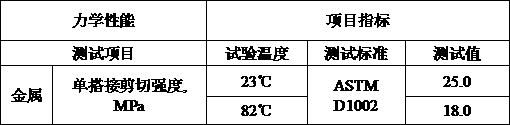

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com