Construction method of anti-seepage wall of hydropower station

A construction method and technology for hydropower stations, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as serious water seepage, hidden safety hazards, and reduced safety of slot holes, and achieve simple construction technology, obvious economic benefits, and convenient quality The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

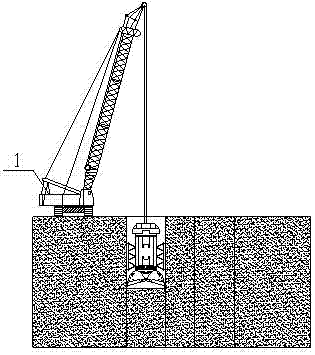

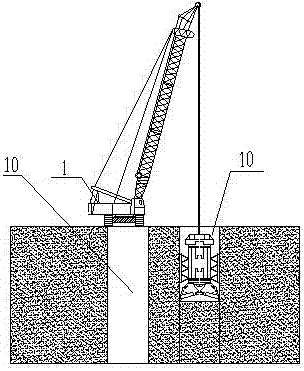

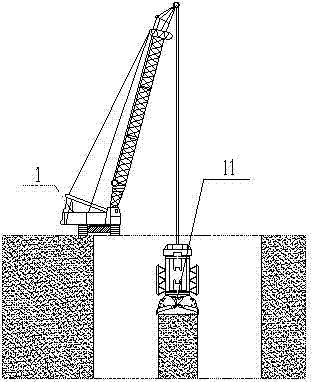

[0035] Such as Figure 1 to Figure 14 As shown, the present invention provides a construction method for the anti-seepage wall of a hydropower station. The anti-seepage wall is arranged on the wall foundation in the hydropower station, and the wall foundation is a soft foundation, cofferdam or dam in the hydropower station. It is characterized in that: the method includes The first-phase groove section construction and the second-phase groove section construction carried out successively on the wall foundation; the first-phase groove section and the second-phase groove section are staggered; the first-phase groove section construction specifically includes the following steps: Step 1 , use grab bucket 1 to grab the first-stage main hole 10 on one side of the wall foundation; step 2, use grab bucket 1 to grab the other side first-stage main hole 10 on the wall foundation; step 3, use grab bucket 1 The first-stage slot hole is formed after grabbing the first-stage intermediate a...

Embodiment 2

[0037] On the basis of Example 1, in the process of grabbing, when a boulder is encountered, any method of drilling and blasting in the groove, energy-concentrating blasting in the groove or heavy chisel (hammer) smashing is used to deal with it.

[0038] The drilling and blasting in the groove is specifically as follows: first, the grab bucket 1 or the percussion drilling rig stops the construction; then the full hydraulic engineering drilling rig is used to drill holes to penetrate the boulder; finally, a blasting tube is installed to blast the boulder. During blasting, the amount of charge in the blasting cylinder is 2-3kg / m according to the length of the rock section. When there are multiple blasting tubes, millisecond detonators are installed to blast in sections to avoid endangering the safety of the slot.

[0039] The energy-concentrating blasting in the groove is specifically: placing an energy-concentrating blasting cylinder under the surface of the boulder for blasti...

Embodiment 3

[0042] On the basis of Example 1, such as Figure 4 and Figure 11 As shown, the first-stage gas lift reverse circulation hole cleaning or the second-stage gas lift reverse circulation hole cleaning is specifically: after the hole shape of the first-stage slot hole or the second-stage slot hole is qualified, first use the grab bucket 1 to remove the first-stage slot Grab the sand and pebbles at the bottom of the hole or the second-stage slot, and then use the air lift method to clean the hole.

[0043] The principle of the gas lift method is to mix the liquid and gas with the help of the gas lift slag discharger, and use the density difference to lift and discharge the mud and sediment at the bottom of the hole. Compressed air enters the mixer from the air pipe, and forms a liquid-gas mixture in the slag discharge pipe 5 with a density lower than that of the mud outside the pipe. Make the mud in the hole carry the sediment at the bottom of the hole to follow up and discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com