Seepage-proof thermal insulation wall material containing fibrous material

A technology for thermal insulation walls and fiber materials, which is applied in the fields of thermal insulation wall materials and anti-seepage thermal insulation wall materials, can solve the problems of immature thermal insulation and energy saving technology, damage to buildings, poor thermal insulation effect, etc., and achieves low thermal conductivity. , Reduce environmental damage, and improve the effect of anti-seepage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

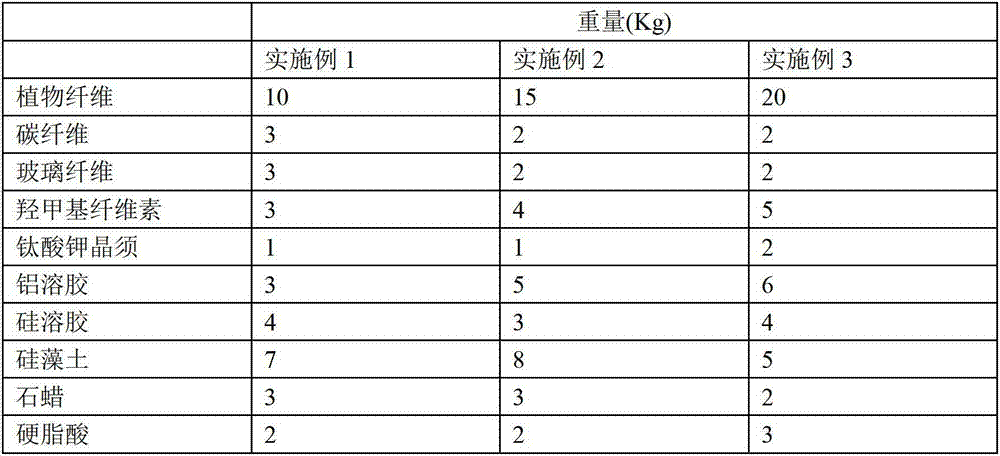

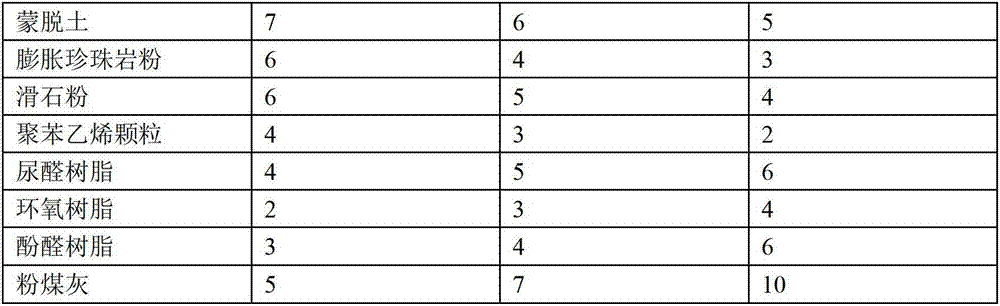

[0016] Weigh each component according to the weight ratio in Table 1

[0017] The weight proportion of table 1 embodiment 1~embodiment 3

[0018]

[0019]

[0020] The preparation method is:

[0021] S1: Weigh the mixture in proportion, add 15-20 parts of water, and stir evenly;

[0022] S2: The wet billet is prepared by mechanical extrusion blooming method or manual blooming method;

[0023] S3: drying at 100°C to 150°C to remove moisture;

[0024] S4: Use mechanical equipment to cut and grind to obtain products.

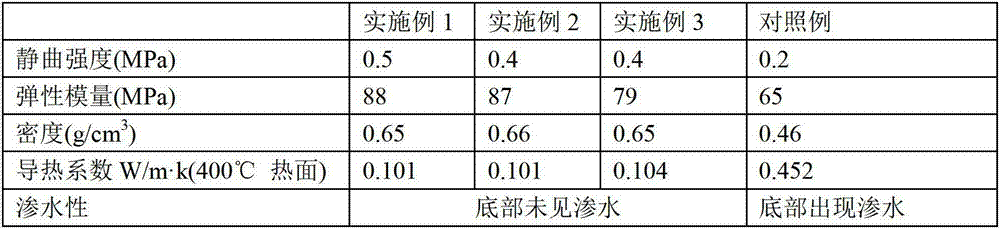

[0025] The performance test results of the thermal insulation wall materials in the above examples are shown in Table 2. In addition, the wall material disclosed in the patent CN02110379 is used as a comparison.

[0026] Among them, the test method of water permeability is: make a 30×30cm test block made of thermal insulation wall material, place it horizontally, seal it with wooden boards around it to form a groove shape, pour clean water in the middle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com