Anti-seepage cofferdam structure and construction process

A construction technique and technology of cofferdams, applied in the direction of infrastructure engineering, construction, etc., can solve problems such as the inability to guarantee the quality of cofferdam seepage prevention, the tight construction period of cofferdams, and the ineffective compaction of materials, etc., to achieve convenient construction methods, The construction method is easy and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

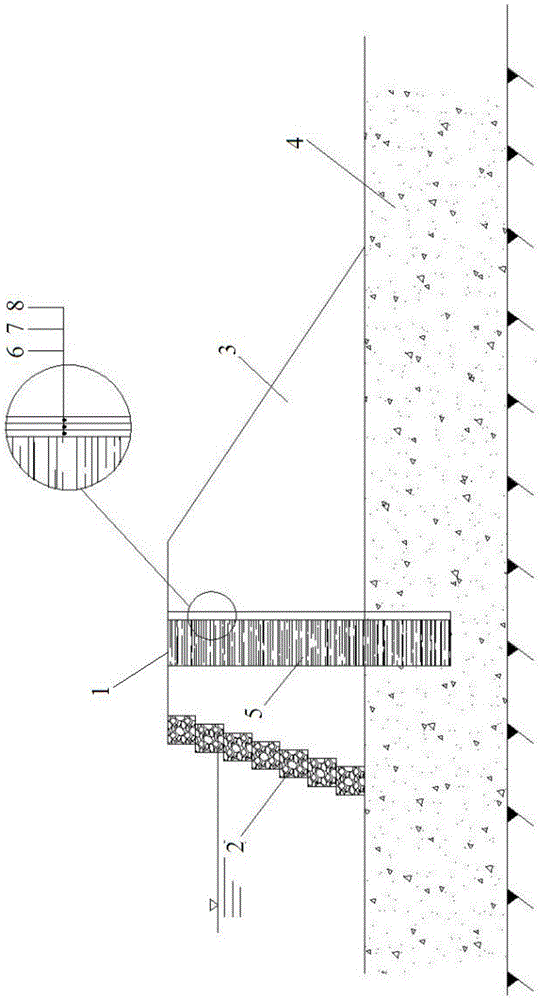

[0024] like figure 1 As shown, the present invention is an anti-seepage cofferdam structure, and the cofferdam structure includes a vertical anti-seepage body 1 arranged in the middle of the end face of the cofferdam. The main body of 1 is filled with multi-layer cemented sand and gravel mixture 5, and a vertical anti-seepage partition layer is provided on one side of the anti-seepage body 1, and the anti-seepage partition layer is between two layers of geotextiles 6 and 8 A layer of geomembrane 7 is interposed, the other side of the anti-seepage partition layer is a trapezoidal cofferdam body 3, and the other side of the anti-seepage body 1 is provided with a lead wire stone dragon 2.

[0025] In the preferred embodiment of the present invention, the cross-section of the vertical anti-seepage body 1 is rectangular, the width of the rectangle is 3 meters, and the depth of the vertical anti-seepage body 1 buried in the riverbed cover layer 4 is 1.2 meters.

[0026] In a prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com