Construction method for processing saline soil roadbed by separation layer

A construction method and technology of partitioning layers, applied in the direction of roads, roads, buildings, etc., can solve problems such as unevenness, swelling, cracking, cracking and damage on the road surface, and affecting the normal operation of vehicles, so as to improve stability and service life, The effect of reducing project cost and easy control of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Treatment measures: clear the saline soil on the surface of the widened part of the subgrade (the thickness of the removal depends on the saline soil), replace it with gravel soil, and set a composite geomembrane to cover the gravel soil partition layer.

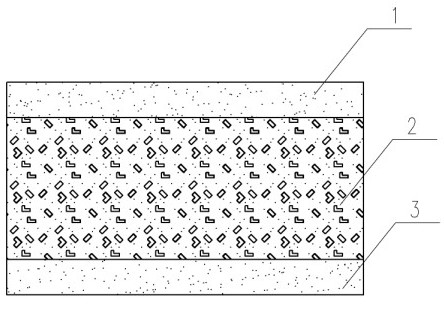

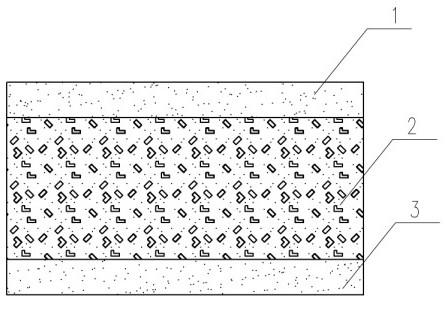

[0026] The subgrade structure layer of this section includes: 3cm thick fine-grained asphalt concrete, 4cm thick medium-grained asphalt concrete, 20cm thick cement stabilized gravel layer, 30cm thick natural graded gravel layer, composite geomembrane-coated isolation layer and the original roadbed surface layer . The cement-stabilized gravel layer contains 4-6% cement, and the cement is made of No. 32.5 ordinary Portland cement, and the rest is gravel; the maximum particle size of the gravel in the natural graded gravel is 5cm, and the soil content is less than 10%.

[0027] Its construction steps are as follows:

[0028] 1. Clear the surface soil of the original pavement layer, and compact it with a compaction degre...

Embodiment 2

[0033] Treatment measures: remove the saline soil on the surface of the subgrade (the thickness of the removal depends on the saline soil), replace it with gravel soil, and set a coarse sand filter layer to cover the gravel soil partition layer.

[0034] The subgrade structure layer of this section includes a 3cm-thick asphalt surface layer, an 18cm-thick cement-stabilized gravel layer, a gravel-soil barrier layer coated with a coarse sand filter layer and the original subgrade surface layer. The cement-stabilized gravel layer contains 4-6% cement, and the cement is made of No. 32.5 ordinary Portland cement, and the rest is gravel. The gravel-soil barrier layer covered by the coarse sand filter layer includes the upper coarse sand filter layer, the gravel barrier layer and the lower coarse sand filter layer. The construction steps are as follows:

[0035] 1. Lay the lower layer of coarse sand filter layer first, with a thickness of 10cm and a compaction degree of over 96%; pav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com