Connecting method and structure for horizontal impervious layer and drainage vertical shaft of red mud yard

A connection method and technology of an anti-seepage layer are applied in the field of sludge disposal in the waste water treatment station of an alumina plant, which can solve the problems of leakage, the sealing of the joint and the uneven foundation, and achieve a simple construction method and solve the sealing and foundation problems. Uneven settlement, good effect of anti-seepage and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

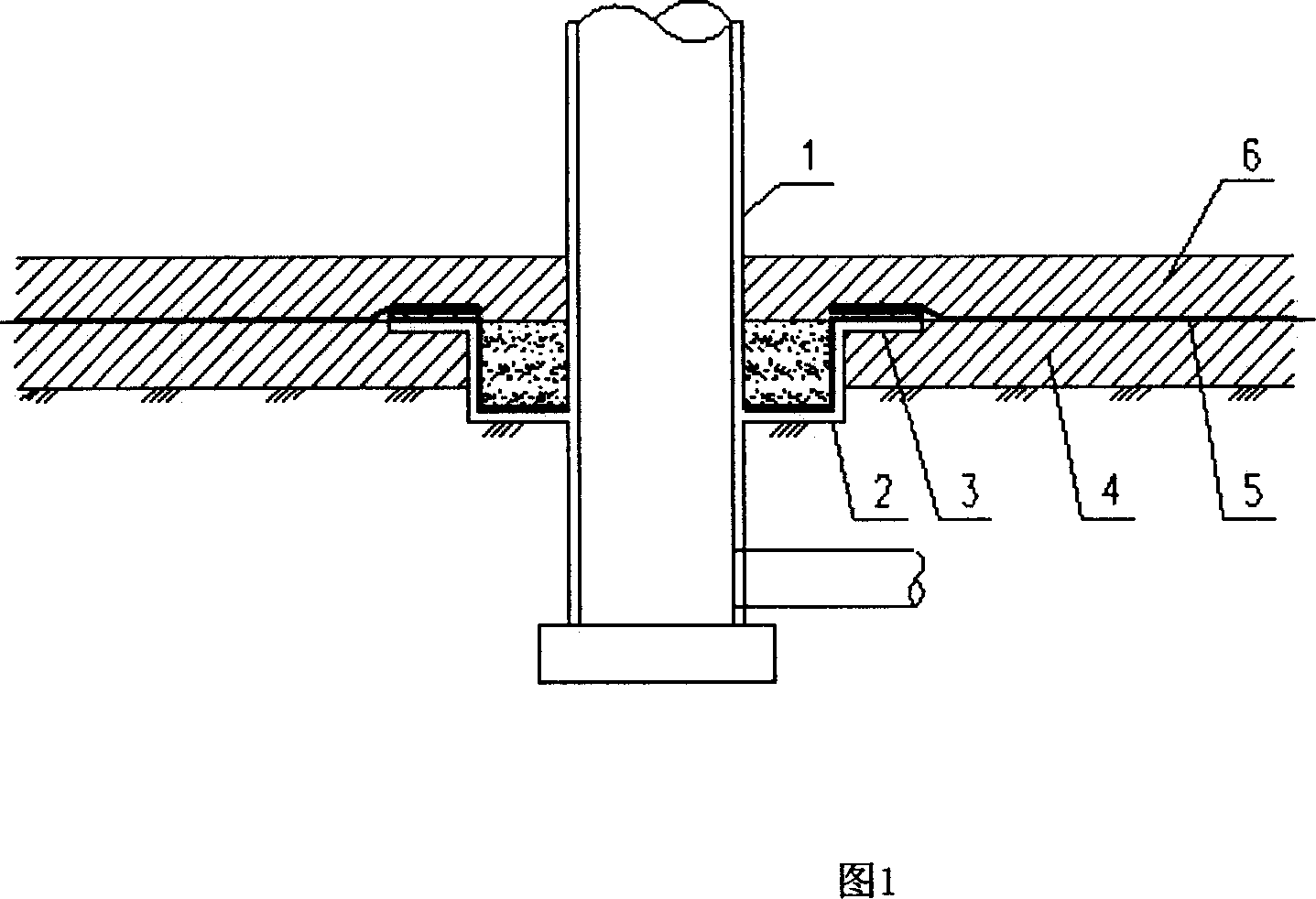

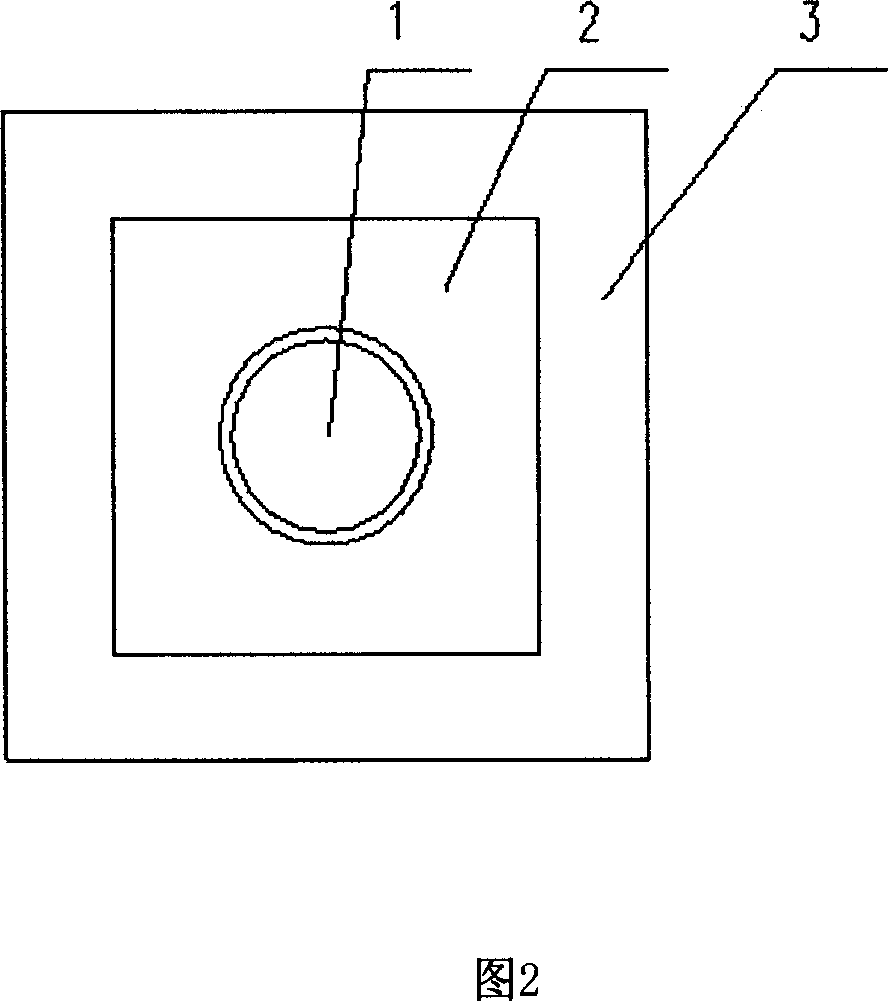

[0016] A square groove (2) is set on the drainage shaft (1), and its material is the same as the shaft. The groove (2) is integrated with the drainage shaft (1). If the drainage shaft (1) is a steel structure, the groove (2) is made of steel plates; if the drainage shaft (1) is a reinforced concrete structure, the groove (2) is also made of reinforced concrete and constructed together with the shaft. Groove (2) depth is about 1m.

[0017] An annular edge (3) is provided outside the groove (2). Its width is estimated based on foundation settlement.

[0018] Then construct the cushion course (4) in the horizontal anti-seepage layer, and its top is flush with the annular edge (3).

[0019] Then lay the composite geomembrane (5). The composite geomembrane is folded once on the annular edge (3), and then laid along the side wall of the groove (2) to the bottom of the groove (2). Concrete is poured in the groove (2) afterwards, and the top of the concrete is flush with the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com