A kind of high wear-resistant concrete material and its preparation method and application

A concrete and high wear-resistant technology, applied in the field of building materials, can solve the problems of reduced wear resistance strength, unstable concrete performance, etc., and achieve the effects of reducing shrinkage deformation, significant energy saving and environmental protection benefits, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

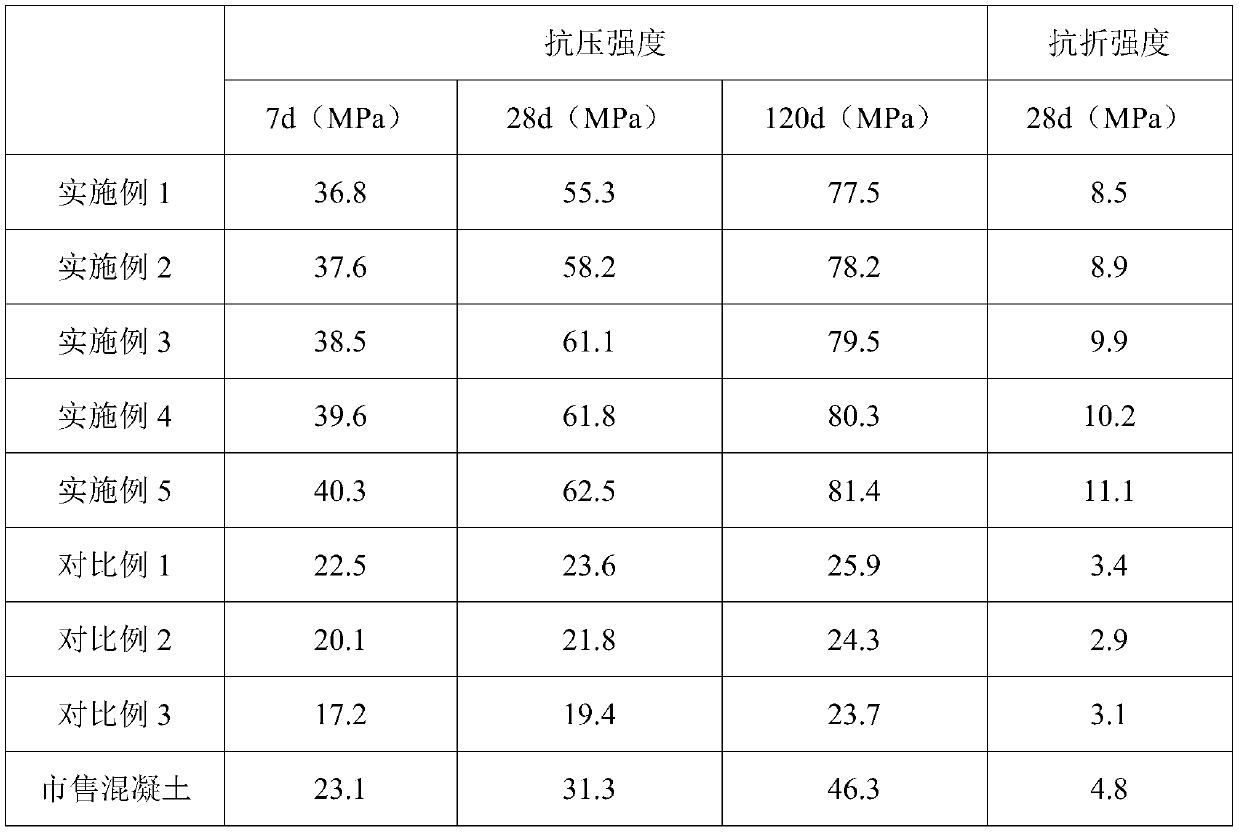

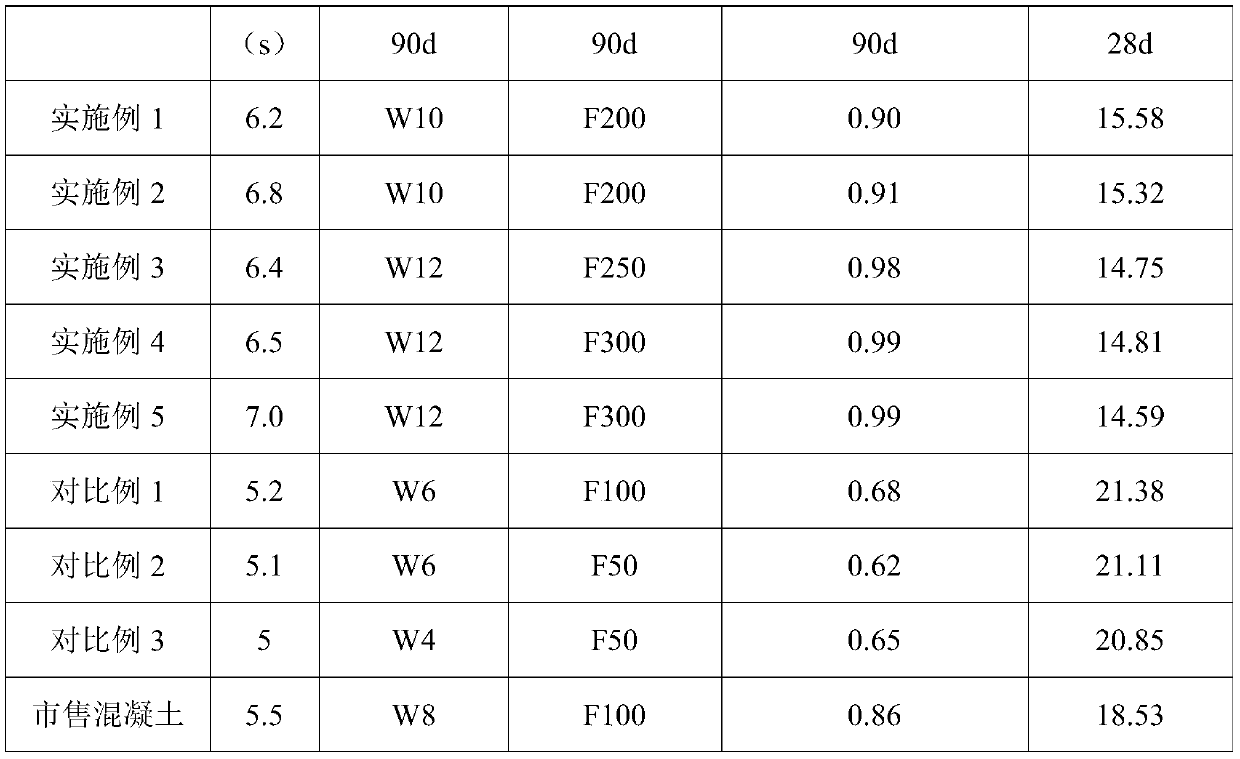

Examples

Embodiment 1

[0022] In the embodiment of the present invention, a highly wear-resistant concrete material comprises the following steps: Portland cement 45kg, fine sand 23kg, polystyrene resin 11kg, cellulose diacetate 7kg, dimethyl sulfoxide 15kg, vermiculite 18kg.

[0023] Mix dimethyl sulfoxide with 4 times its mass of water to prepare a dimethyl sulfoxide solution. Mix and crush vermiculite and cellulose diacetate, pass through a 100-mesh sieve, then mix with dimethyl sulfoxide solution, heat to 75°C and seal and stir at this temperature for 1.8h, with a stirring speed of 200r / min. The precipitate was collected by centrifugation, washed and dried to obtain pretreated vermiculite; the centrifugal speed was 3000r / min, and the centrifugal time was 10min. Add polystyrene resin to the pretreated vermiculite, ball mill for 45min, and the mass ratio of ball to material during ball milling is 5:1. Then mix it with Portland cement and fine sand, and stir evenly; the stirring speed is 120r / min...

Embodiment 2

[0025] In the embodiment of the present invention, a highly wear-resistant concrete material comprises the following steps: Portland cement 55kg, fine sand 31kg, polystyrene resin 19kg, cellulose diacetate 15kg, dimethyl sulfoxide 25kg, vermiculite 26kg.

[0026] Mix dimethyl sulfoxide with 5 times its mass of water to prepare a dimethyl sulfoxide solution. Mix and crush vermiculite and cellulose diacetate, pass through a 150-mesh sieve, then mix with dimethyl sulfoxide solution, heat to 78°C and seal and stir at this temperature for 2 hours at a stirring speed of 220r / min. The precipitate was collected by centrifugal separation, washed and dried to obtain pretreated vermiculite; the centrifugal speed was 3000r / min, and the centrifugal time was 20min. Add polystyrene resin to the pretreated vermiculite, ball mill for 50min, and the mass ratio of ball to material during ball milling is 5:1. Then mix it with Portland cement and fine sand, and stir evenly; the stirring speed is...

Embodiment 3

[0028] In the embodiment of the present invention, a highly wear-resistant concrete material comprises the following steps: Portland cement 48kg, fine sand 25kg, polystyrene resin 13kg, cellulose diacetate 9kg, dimethyl sulfoxide 18kg, vermiculite 20kg.

[0029] Mix dimethyl sulfoxide with 5 times its mass of water to prepare a dimethyl sulfoxide solution. Mix and crush vermiculite and cellulose diacetate, pass through a 150-mesh sieve, then mix with dimethyl sulfoxide solution, heat to 76°C and seal and stir at this temperature for 1.9h, with a stirring speed of 220r / min. The precipitate was collected by centrifugal separation, washed and dried to obtain pretreated vermiculite; the centrifugal speed was 3000r / min, and the centrifugal time was 15min. Add polystyrene resin to the pretreated vermiculite, ball mill for 50min, and the mass ratio of ball to material during ball milling is 5:1. Then mix it with Portland cement and fine sand, and stir evenly; the stirring speed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com