Pre-paving anti-sticking waterproof structure and construction method

A waterproof structure, pre-laid and anti-adhesion technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve problems such as poor resistance to deformation, leakage points, waterproof layer damage, etc., and achieve anti-deformation and anti-crack resistance. ability, good water channeling resistance, and the effect of good water channeling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

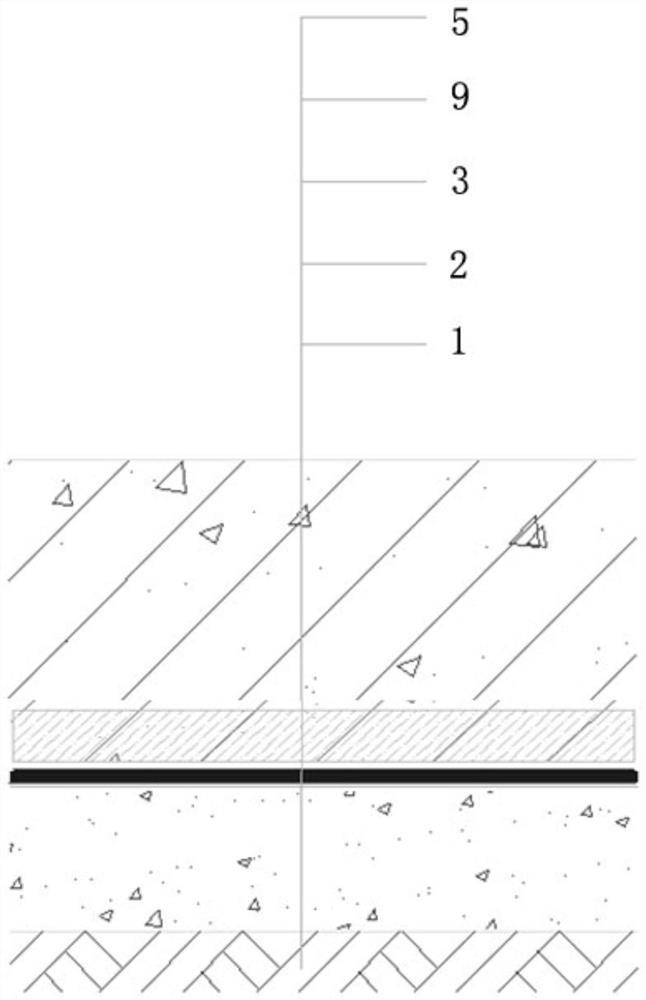

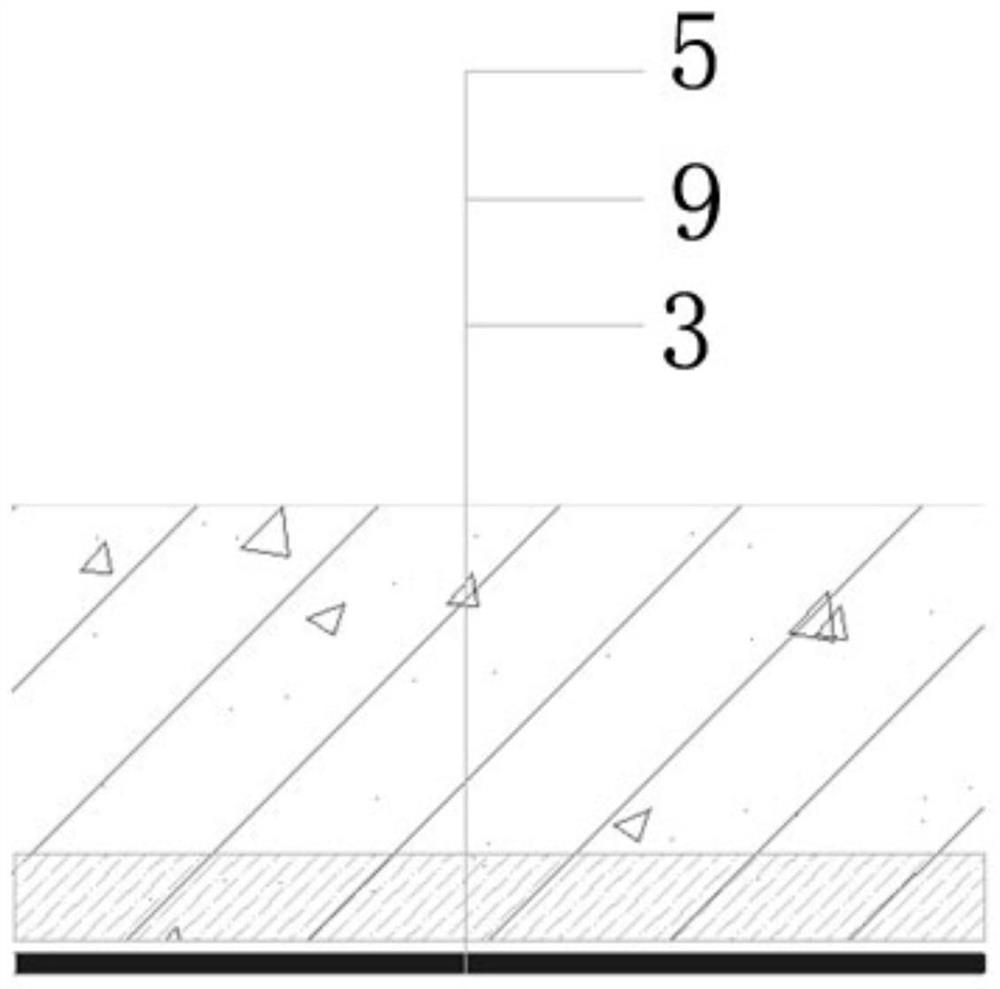

[0053] This embodiment provides a pre-paved anti-adhesive waterproof structure, such as figure 1 As shown, the structure includes a concrete cushion 2 , a pre-laid polymer waterproof membrane layer 3 , an impervious self-repairing waterproof layer 9 and an impermeable concrete layer 5 from bottom to top.

[0054] The impervious self-repairing waterproof layer 9 is dispersed to the impermeable concrete layer 5 from the cement-based osmotic crystalline waterproof material that is dry-scattered on the pre-laid polymer waterproof membrane layer 3 and is in contact with the cement-based osmotic crystalline waterproof material. formed by parts, such as image 3 shown.

[0055] The thickness of the concrete cushion 2 is 100mm, and the concrete of the concrete cushion 2 is C15 concrete.

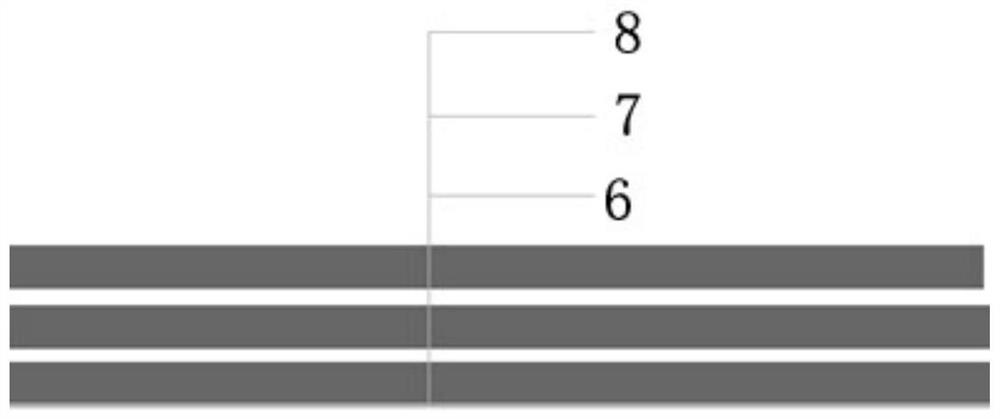

[0056] The thickness of the pre-laid polymer waterproof membrane layer 3 is 1.5mm; the pre-laid polymer waterproof membrane layer 3 includes a bottom film 6, a self-adhesive adhesive layer 7 and an...

Embodiment 2

[0064] This embodiment provides a pre-paved anti-adhesive waterproof structure. The difference between this embodiment and Embodiment 1 is that the amount per square meter of the cement-based permeable crystalline waterproof material on the pre-paved polymer waterproof membrane layer 3 is 2.0kg.

Embodiment 3

[0066] This embodiment provides a pre-paved anti-adhesive waterproof structure. The difference between this embodiment and Embodiment 1 is that the amount per square meter of the cement-based permeable crystalline waterproof material on the pre-paved polymer waterproof membrane layer 3 is 0.5kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com