Liquid lightening agent and preparation and application thereof

A lightening agent and liquid technology, applied in solid waste management, chemical instruments and methods, sustainable waste treatment, etc., can solve the problems of difficult further adjustment of cement slurry density, inability to meet rapid drilling, low 24h waiting setting strength, etc. Achieve the effects of weakening the floating phenomenon, easy industrial production, and stable performance of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

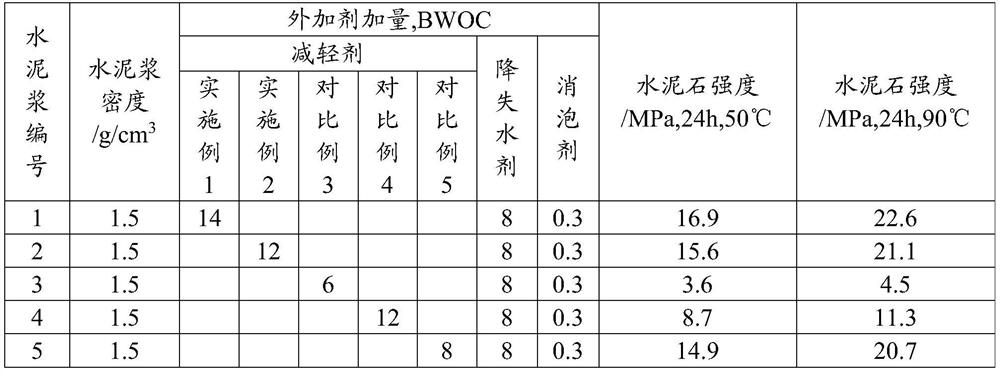

Examples

Embodiment 1

[0057] In this embodiment, the hollow microspheres are processed as follows:

[0058] The hollow microspheres were purchased from Sinosteel Ma'anshan Mining Institute New Material Technology Co., Ltd., model H6000;

[0059] 1) Treating the hollow microspheres in a solution with a pH value of 12 for 2 hours, neutralizing the alkaline substances on the surface of the hollow microspheres after treatment and drying;

[0060] 2) Add the mixture of ammonia, ethanol and water to the hollow microspheres treated in step 1) for 0.5h; the weight ratio of the hollow microspheres to the mixed solution is 2.2:15.6; the volume of ammonia, ethanol and water The ratio is 0.1:2:6;

[0061] 3) Mix the mixture obtained in step 2) with ethyl orthosilicate and treat for 4 hours, the mass ratio of ethyl orthosilicate to the mixed liquid obtained in step 2) is 0.93:12.4;

[0062] 4) The mixture in step 3) was separated from solid and liquid, washed with ethanol and water for several times, filtered...

Embodiment 2

[0070] In this embodiment, the hollow microspheres are processed as follows:

[0071] The hollow microspheres were purchased from Zhongke Huaxing New Material Co., Ltd., model D4000;

[0072] 1) Treating the hollow microspheres in a solution with a pH value of 11 for 3 hours, neutralizing the alkaline substances on the surface of the hollow microspheres after treatment and drying;

[0073] 2) adding the mixture of ammonia, ethanol and water to the hollow microspheres treated in step 1) for 0.5h; the weight ratio of the hollow microspheres to the mixed solution is 1.8:19.8; the volume of ammonia, ethanol and water The ratio is 0.05:4:6;

[0074] 3) Mix the mixture obtained in step 2) with ethyl orthosilicate, and treat for 4 hours, the mass ratio of ethyl orthosilicate to the mixture is 0.86:13.4;

[0075] 4) The mixture in step 3) is separated from solid and liquid, and the solid matter is calcined at 130° C. for 2 hours to obtain coated modified hollow microspheres.

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com